Method for preparing slot field-effect transistor with back-gate ZnO multi-nano wire

A manufacturing method and transistor technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of the gap, the small working current of ZnO nanowire field effect transistors, etc., and achieve the effect of increasing the current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in combination with specific embodiments and with reference to the accompanying drawings.

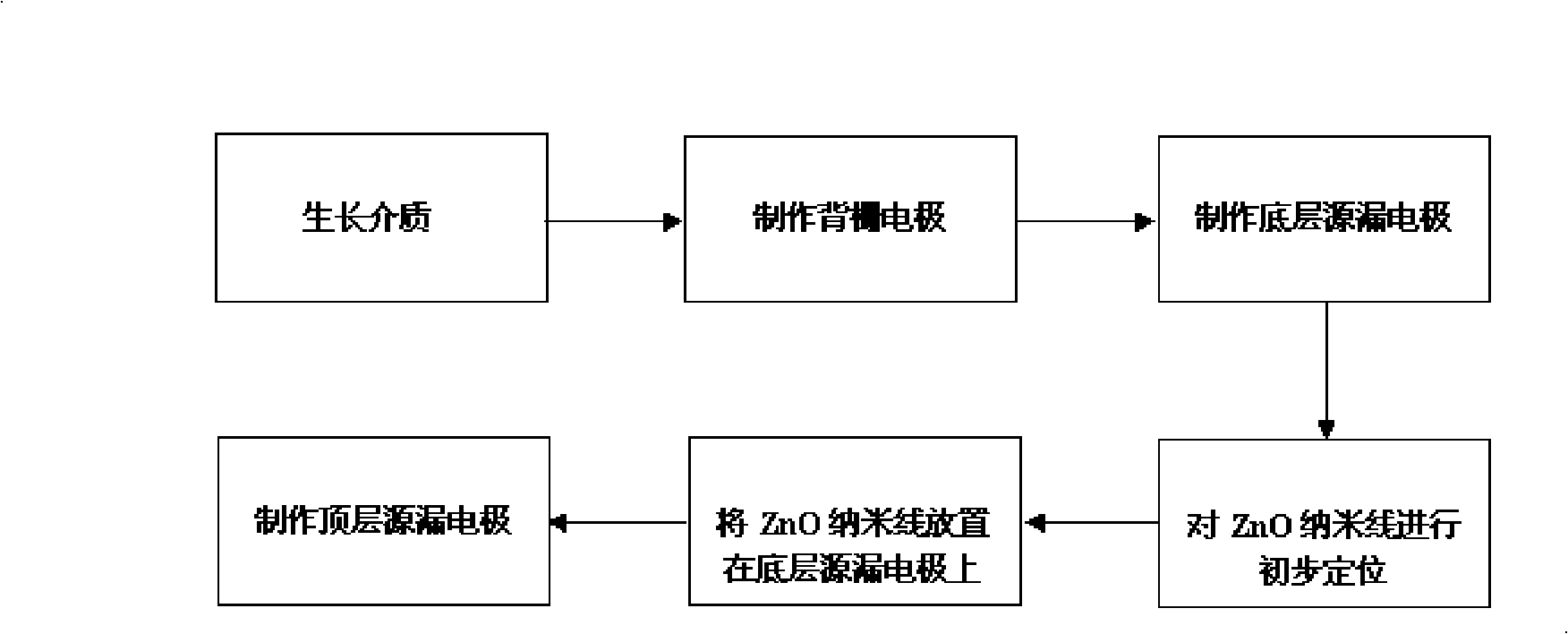

[0028] see figure 1 and figure 2 , a method for manufacturing a back gate ZnO multi-nanowire trench field effect transistor, the steps of the method are as follows:

[0029] (1) On the upper surface of the substrate 1, use RF plasma enhanced chemical vapor deposition technology PECVD to grow SiO 2 Dielectric 2 is used as a gate oxide dielectric;

[0030] (2) evaporating metal on the back side of the substrate 1 as the back gate electrode 3;

[0031] (3) Electrode metal is made on the upper surface of the substrate through steps such as photolithography, evaporation, and stripping, as the bottom source and drain electrodes 4;

[0032] (4) Using AC bidirectional dielectrophoresis technology to initially immobilize ZnO nanowires 5, the process is as follows: put the ZnO nanowire material into an isopropanol solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com