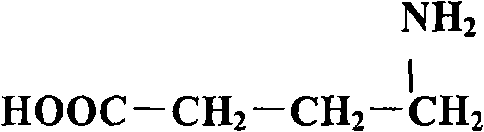

Method for producing gamma-aminobutyric acid by separated fermentation of enterococcus faecium

A technology of aminobutyric acid and Enterococcus faecium, which is applied in the biological field to achieve the effects of improving utilization rate, convenient operation and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preserved strains of Enterococcus faecium were activated on MRS slope, inserted into MRS or TYG or improved PD seed medium, stirred and cultured at 30-37°C, 100-180rpm for 12-24h, and then inserted into MRS or 4-10% TYG or improved PD fermentation medium, at 30-37°C, under stirring at 100-180rpm, add 1mol / L NaOH to control the pH6.0-7.0 culture for 24h, then remove the pH control, continue to ferment for 12-18h, press 15-40g Add glutamic acid or sodium glutamate at a ratio of final concentration / L, and continue to ferment at 35-45°C, pH 3.0-5.0 for 24-96 hours, so as to obtain a fermentation with a γ-aminobutyric acid content of 10-20g / L mash.

Embodiment 2

[0045] Enterococcus faecium is used as the production strain, firstly use the MRS slope to activate, and then use the MRS liquid culture in the triangular flask to activate based on 30-37°C, 100rpm shaker culture for 12h, and then insert 4-10% of the inoculum into MRS or TYG or improved PD seed medium, at 30-37°C, 100-180rpm, stir culture for 12-24h, then insert 4-10% into MRS or TYG or improved PD fermentation medium, at 30-37°C, 100-180rpm Under stirring, add 1mol / L NaOH to control the pH6.0~7.0 and cultivate for 24h, then release the pH control, continue to ferment for 12~18h, add glutamic acid or sodium glutamate at a ratio of 15~40g / L final concentration, The pH value is controlled at 3.0-5.0 by feeding NaOH and HCl and the fermentation is continued at 35-45° C. for 24-96 hours, thereby obtaining fermented mash with a content of γ-aminobutyric acid of 10-20 g / L. After sterilized discharge, GABA can be extracted and refined.

Embodiment 3

[0047] Enterococcus faecium is used as the production strain, firstly use the MRS slope to activate, and then use the MRS liquid culture in the triangular flask to activate based on 30-37°C, 100rpm shaker culture for 12h, and then insert 4-10% of the inoculum into MRS or TYG or improved PD seed medium, at 30-37°C, 100-180rpm, stir culture for 12-24h, then insert 4-10% into MRS or TYG or improved PD fermentation medium, at 30-37°C, 100-180rpm Under stirring, add 1mol / L NaOH to control the pH6.0~7.0 and cultivate for 24~36h, add glutamic acid or sodium glutamate at a ratio of 15~40g / L final concentration, and control the pH value by feeding NaOH and HCl Continue to ferment at 3.0-5.0 at 35-45° C. for 24-96 hours to obtain fermented mash with γ-aminobutyric acid content of 10-20 g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com