Method for weight-increasing and antimicrobial treatment of silk fiber

A silk and fiber technology, which is applied in the field of weight gain modification and finishing of silk fibers, can solve the problems of wasting sericin resources, poor antibacterial properties of silk fibers, and environmental pollution, and achieve the goals of reducing pollution, improving efficiency, and improving flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

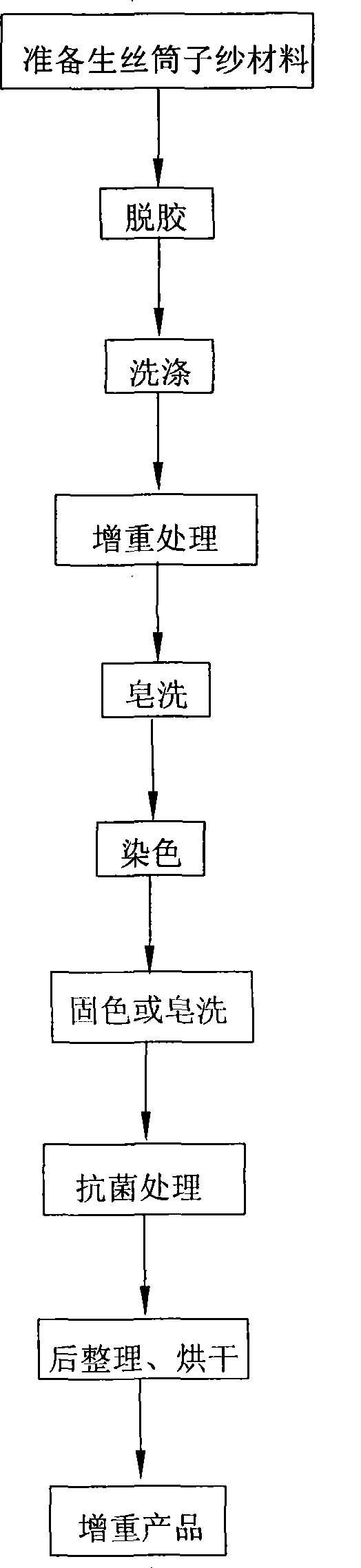

[0013] See attached figure 1 Shown. A method for weight gain and antibacterial treatment of real silk fibers, including the following steps: preparing raw silk cheese yarn material-degumming treatment with silk refining agent-washing treatment-weight gain treatment-soaping-dyeing-fixing Or soaping-antibacterial treatment-finishing, drying-weight gain (modified) products.

[0014] In the step of preparing the raw silk cheese yarn material, silk fiber is selected as an example, and 100Kg of pure silk fiber is weighed as the material to be processed.

[0015] In the degumming treatment step, silk refining agent is used to remove sericin protein according to a conventional process, and then washed with hot water at 100° C., washed with warm water at 70° C., and washed with cold water at room temperature.

[0016] In the weight gain treatment step, the grafting solution is prepared first: the grafting monomer is a derivative of methacrylate, such as methyl methacrylate, ethyl methacry...

Embodiment 2

[0025] See attached figure 1 Shown. A method for weight gain and antibacterial treatment of silk fiber, the steps are the same as in Example 1.

[0026] The steps of preparing raw silk cheese yarn material and degumming are the same as in Example 1.

[0027] In the weight gain treatment step, the grafting solution is prepared first: the grafting monomer is a derivative of methacrylate, such as methyl methacrylate, ethyl methacrylate, propyl methacrylate or methacrylic acid. One or more mixtures of butyl ester, the added amount is 66% of the fabric weight; ammonium persulfate is used as the initiator; the non-ionic surfactant adopts a flat addition of O, and the added amount is 0.8g / l; disperse Agent WA, the addition amount is 1g / l; soft water is used as the solvent, and the bath ratio is 1:15; the pH value of the grafting solution is adjusted to 3~4 with a mixture of formic acid and acetic acid. The weight gain treatment step is carried out in a closed full immersion high tempera...

Embodiment 3

[0032] See attached figure 1 Shown. A method for weight gain and antibacterial modification of silk fiber, the steps are the same as in Example 1.

[0033] The steps of preparing raw silk cheese yarn material and degumming are the same as in Example 1.

[0034] In the weight gain treatment step, the grafting solution is prepared first: the grafting monomer is a derivative of methacrylate, such as methyl methacrylate, ethyl methacrylate, propyl methacrylate or methacrylic acid One or more mixtures of butyl esters are added in an amount of 66% of the fabric weight; and 10%, 20%, and 30% of the fabric weight are added respectively with degumming wastewater; ammonium persulfate is used as an initiator; Non-ionic surface active agent adopts flat addition of O, and the addition amount is 0.8g / l; dispersant WA, the addition amount is 1g / l; solvent uses soft water, bath ratio is 1:15; uses formic acid and acetic acid mixture to adjust the grafting The pH value of the liquid is 3~4. The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com