Method for the annealing preparation of tantalum scandium acid plumbum-based ferroelectric film by two step method

A technology of lead tantalum scandate and ferroelectric thin films, which is applied in the field of preparation of lead tantalum scandate-based ferroelectric thin films, can solve the problem of compositional deviation of lead tantalum scandate-based ferroelectric thin films, and achieve high purity and extremely high perovskite phase. Highly preferred orientation of chemical strength and good crystallization performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

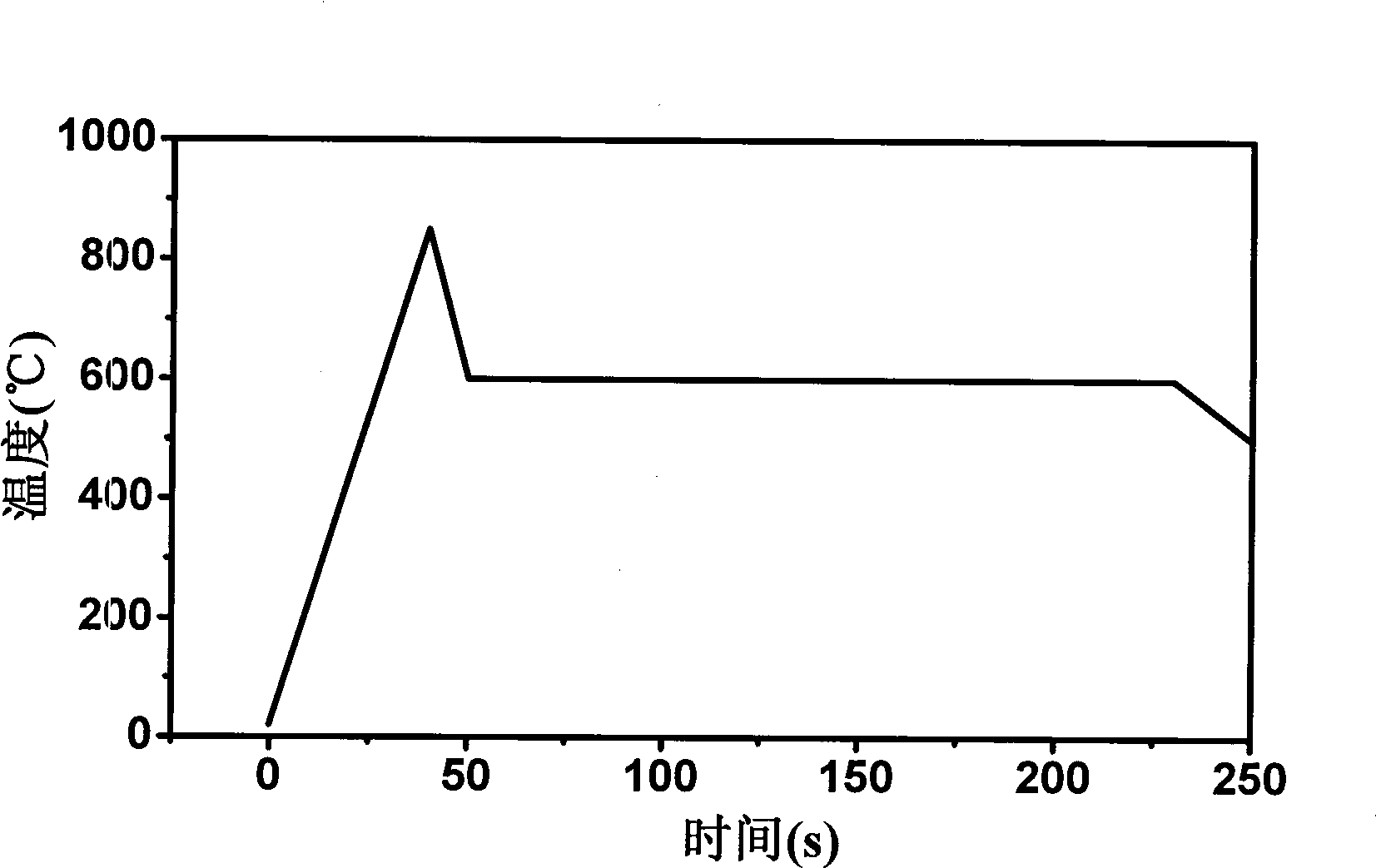

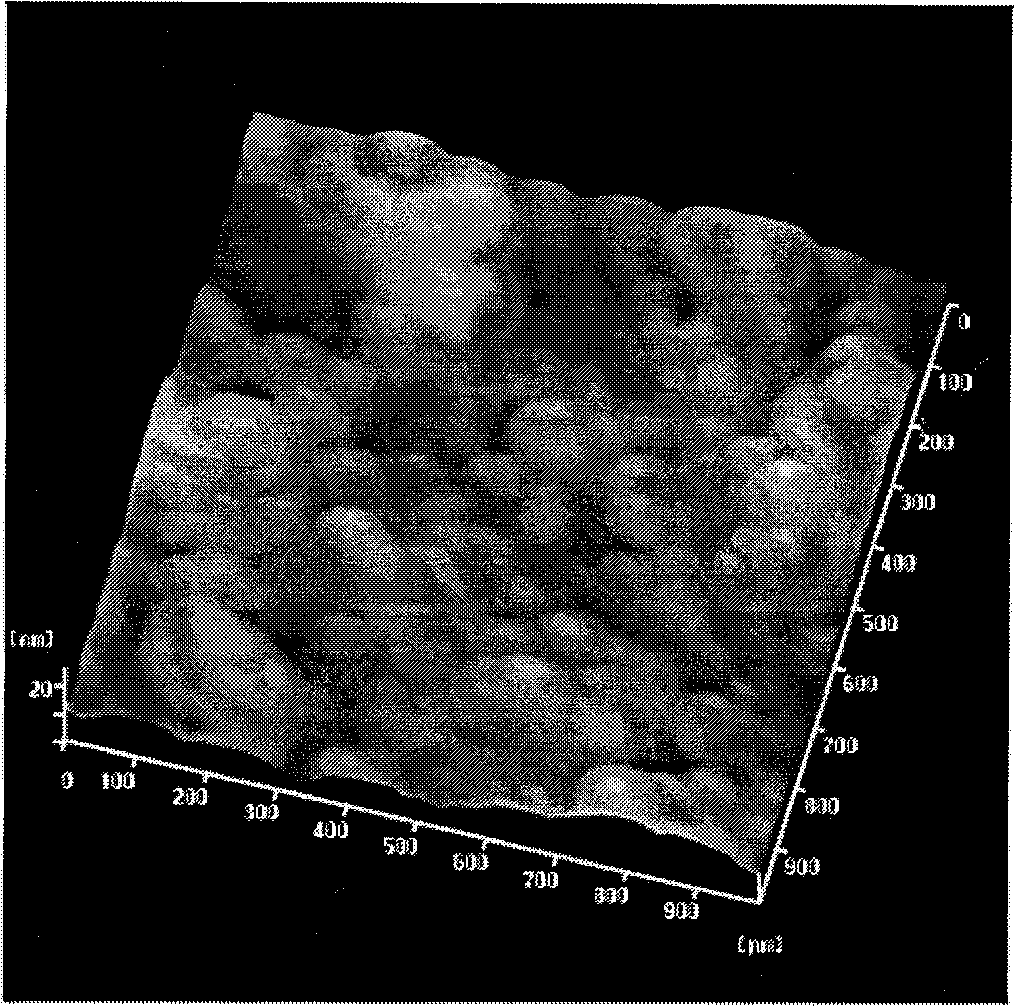

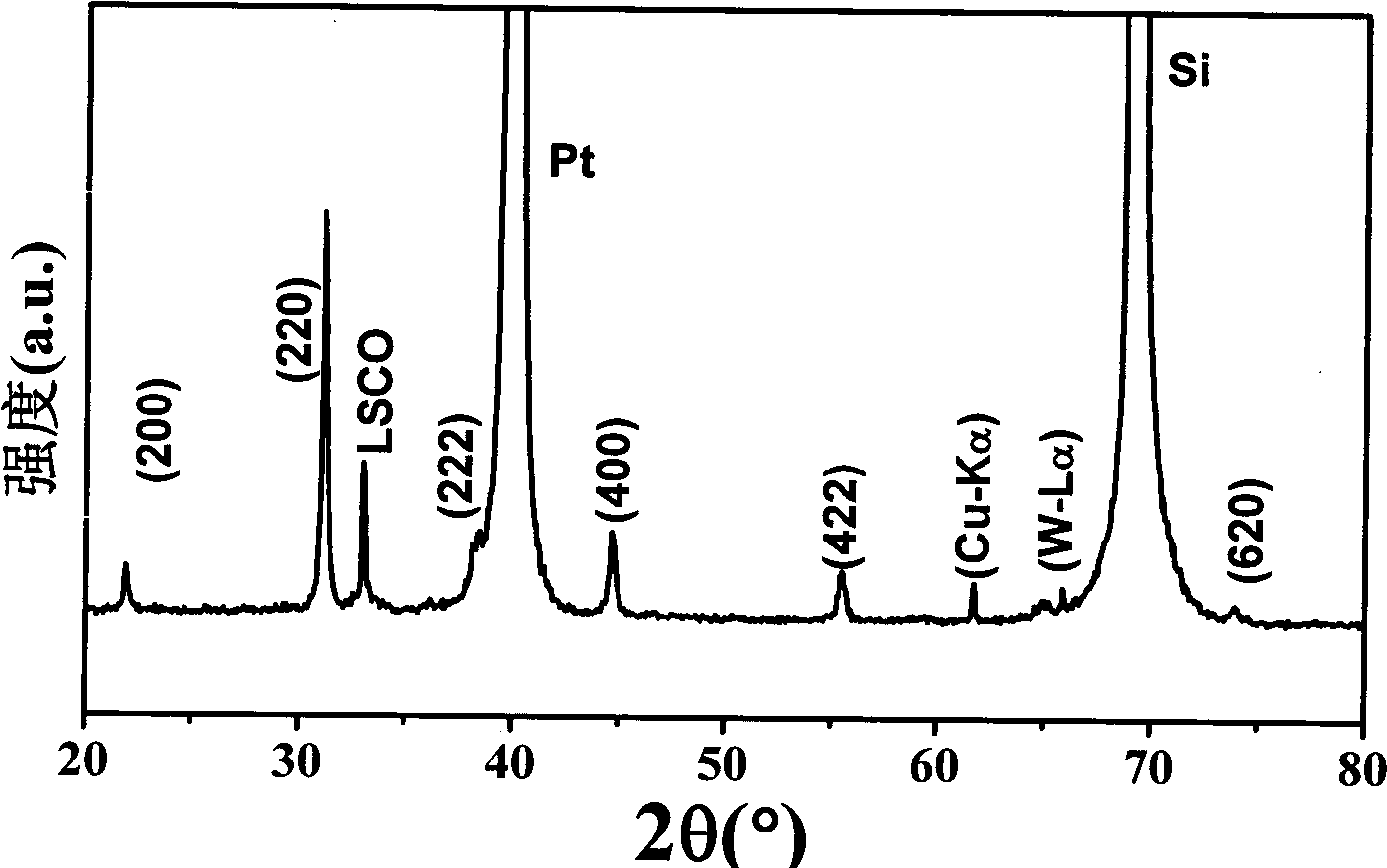

[0024] The present embodiment prepares 0.95Pb(Sc 0.5 Ta 0.5 )O 3 -0.05PbTiO 3 Ferroelectric thin film (abbreviated as PSTT5), the process steps are as follows:

[0025] (1) Processing of the substrate

[0026] The substrate is Pt / Ti / SiO 2 / Si, the substrate was ultrasonically cleaned in toluene for 5 minutes, then in acetone for 5 minutes, and finally in absolute ethanol for 5 minutes.

[0027] (2) Preparation of transition layer

[0028] Sputtering is used to prepare the transition layer, and the substrate cleaned in step (1) is fixed on the substrate position of the sputtering device. The target is La 0.5 Sr 0.5 CoO 3 , according to La 0.5 Sr 0.5 CoO 3 The stoichiometric ratio of weighing raw materials PbO, La 2 o 3 、Co 2 o 3 and SrCO 3 , the raw materials are made into targets by traditional ceramic synthesis process. The target is fixed on the target position of the sputtering device, and the distance between the target and the substrate is 5 cm. The spu...

Embodiment 2

[0036] The present embodiment prepares 0.95Pb(Sc 0.5 Ta 0.5 )O 3 -0.05PbTiO 3 Ferroelectric thin film (abbreviated as PSTT5), the process steps are as follows:

[0037] (1) Processing of the substrate

[0038] The substrate is Pt / Ti / SiO 2 / Si, the cleaning treatment is the same as in Example 1.

[0039] (2) Preparation of transition layer

[0040] Sputtering is used to prepare the transition layer, and the substrate cleaned in step (1) is fixed on the substrate position of the sputtering device. The target is La 0.5 Sr 0.5 CoO 3 , according to La 0.5 Sr 0.5 CoO 3 The stoichiometric ratio of weighing raw materials PbO, La 2 o 3 、Co 2 o 3 and SrCO 3 , the raw materials are made into targets by traditional ceramic synthesis process. The target is fixed on the target position of the sputtering device, and the distance between the target and the substrate is 5 cm. The sputtering conditions are as follows: the background vacuum is 3×10 -4 Pa, the atmosphere used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Root mean square roughness | aaaaa | aaaaa |

| Remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com