Method for preparing SiCp/AZ61 magnesium-based nano composite material using ultrasonic wave

A nano-composite material and ultrasonic technology, which is applied in the field of metal material preparation, can solve the problems of complex process, difficult and uniform distribution of reinforcing phases, and high cost, and achieve the effects of simple preparation process, no pollution of three wastes, and high ductility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] First, add the nano-SiC powder into the ethanol solution for ultrasonic dispersion pretreatment, then dry and grind the pretreatment mixed solution; put the AZ61 magnesium alloy into the crucible and heat it to melt, and keep it warm at 640°C. Extend the horn below the surface of the melt, and ultrasonicate for 5 minutes under the ultrasonic power of 650W; wrap the pretreated nano-SiC powder with 0.5% by mass percentage with tin foil, and add it to the AZ61 magnesium alloy melt In vivo, ultrasonic treatment for 15 minutes, casting sampling.

[0013] In this example, the tensile strength of the nano-SiC particle-reinforced AZ61 magnesium-based composite material reaches 295 MPa, which is 13.5% higher than that of the matrix, its Vickers hardness reaches 61.2, and the elongation rate is 13.8%.

Embodiment 2

[0015] First, add the nano-SiC powder into the ethanol solution for ultrasonic dispersion pretreatment, and then dry and grind the pretreatment mixed solution; put the AZ61 magnesium alloy into the crucible and heat it to melt, and keep it warm at 650°C. Extend the horn below the surface of the melt, and ultrasonicate for 10 minutes under 600W ultrasonic power; wrap the pretreated nano-SiC powder with 1.0% by mass percentage of tin foil, and add it to the AZ61 magnesium alloy melt In vivo, ultrasonic treatment for 20 minutes, casting sampling.

[0016] In this embodiment, the tensile strength of the AZ61 magnesium-based composite material reinforced with nano-SiC particles reaches 325 MPa, which is 25% higher than that of the matrix, and its Vickers hardness reaches 70.4. , and the elongation was 13.4%.

Embodiment 3

[0018] First, add the nano-SiC powder into the ethanol solution for ultrasonic dispersion pretreatment, then dry and grind the pretreatment mixed solution; put the AZ61 magnesium alloy into the crucible and heat it to melt, and keep it warm at 645°C. Extend the horn below the surface of the melt, and ultrasonicate for 8 minutes under the ultrasonic power of 600W; wrap the pretreated nano-SiC powder with 1.5% by mass percentage with tin foil, and add it to the AZ61 magnesium alloy melt In vivo, ultrasonic treatment for 18 minutes, casting samples.

[0019] In this example, the tensile strength of the nano-SiC particle reinforced Az61 magnesium-based composite material reaches 316MPa, which is 21.5% higher than that of the matrix; its Vickers hardness reaches 74.6. , the elongation rate was 13.1%. .

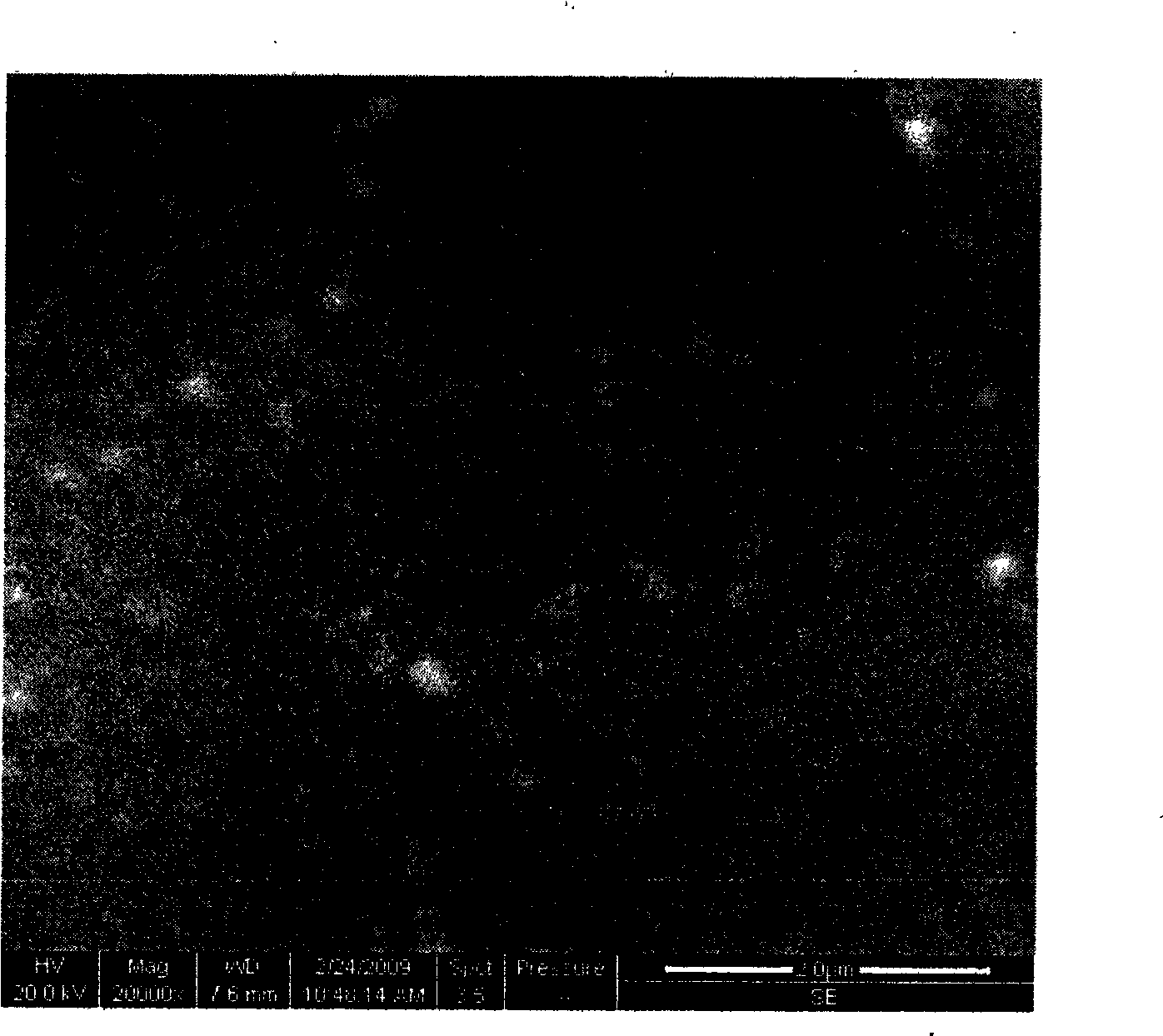

[0020] From the dispersion of nano-SiC particles in AZ61 magnesium alloy in Figure 1, it can be seen that due to the different electrical conductivity of SiC and magnesium alloy,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com