Method for preparing antimony pentafluoride

A technology of antimony pentafluoride and antimony trioxide, applied in chemical instruments and methods, inorganic chemistry, antimony compounds, etc., can solve the problems of high impurity content in finished products, high melting point, and difficult purification of products, and achieve reliable product quality, Easy to control, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

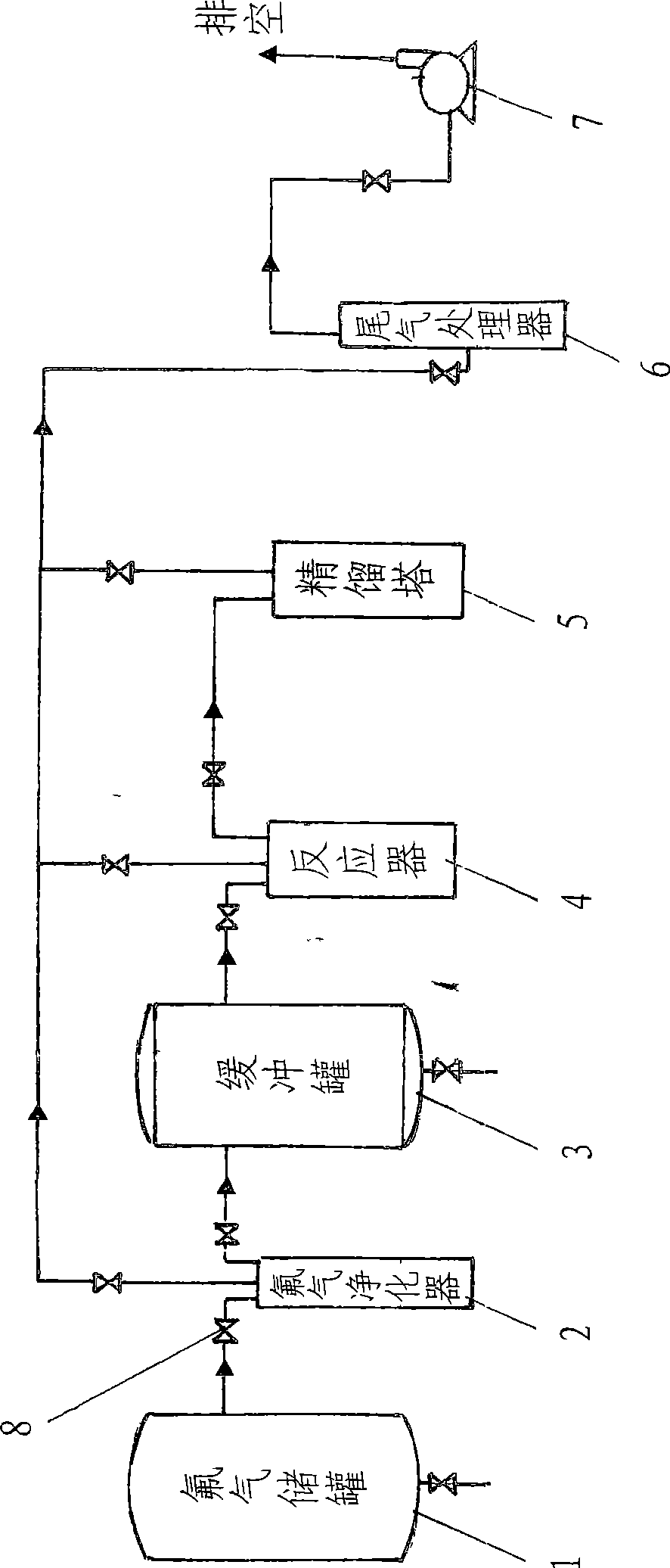

[0031] The preparation method of antimony pentafluoride of the present invention comprises the following steps:

[0032] (i) Fluorine gas purification

[0033] First, pass the fluorine gas in the fluorine gas storage tank 1 into the fluorine gas purifier 2 for freezing and liquefaction, and use the liquid nitrogen cold trap outside the fluorine gas purifier 2 to maintain the temperature of the fluorine gas purifier 2 at -140~- Between 195°C, the fluorine gas is liquefied at this time, and the impurity gases that cannot be condensed, such as hydrogen, oxygen and nitrogen, and other high-boiling substances are still in the gaseous state. Start the vacuum unit 7 to evacuate the impurity gas that cannot be condensed.

[0034] Then, by increasing the temperature of the fluorine gas purifier 2, the liquid fluorine is gasified to obtain a fluorine gas with a purity of more than 99%. Finally, the purified fluorine gas is input to the buffer tank 3 through pipelines, ready for compou...

Embodiment 1

[0044] First, purify the reactor 4, add 25 kg of antimony trioxide with a purity of 98.5% into the reactor 4; close the reactor, evacuate to -0.08MPa, and then preheat the reactor 4 to 100°C. Pass the purified fluorine gas in the buffer tank 3 into the reactor 4 .

[0045] During the reaction process, the temperature in the reactor was kept at 150°C. When the temperature of the reactor tended to drop significantly, the flow of fluorine gas was stopped to check that the reaction was terminated, and a liquid antimony pentafluoride crude product containing light impurities was obtained.

[0046] The liquid antimony pentafluoride crude product is pumped into the rectification tower for collection by means of negative pressure. First, the rectification tower is heated and the temperature is controlled at 100°C. As the temperature in the rectification tower rises, the liquid antimony pentafluoride begins to distill, vaporize and rise. The gas phase in the rectification tower rises ...

Embodiment 2

[0049] First, purify the reactor 4, add 25 kg of antimony trioxide with a purity of 98.5% into the reactor 4; close the reactor, evacuate to -0.08MPa, and then preheat the reactor 4 to 150°C. Pass the purified fluorine gas in the buffer tank 3 into the reactor 4 .

[0050] During the reaction process, the temperature in the reactor was kept at 200°C. When the temperature of the reactor tended to drop significantly, the flow of fluorine gas was stopped to check the termination of the reaction, and a liquid antimony pentafluoride crude product containing light impurities was obtained.

[0051] The liquid antimony pentafluoride crude product is pumped into the rectification tower for collection by means of negative pressure. First, the rectification tower is heated and the temperature is controlled at 125°C. As the temperature in the rectification tower rises, the liquid antimony pentafluoride begins to distill, vaporize and rise. The gas phase in the rectification tower rises t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com