Ultrahard TiB2/Si3N4 nano-multilayer film and preparation method thereof

A nano-multi-layer and multi-layer film technology, applied in coatings, layered products, metal material coating processes, etc., can solve problems such as low hardness, high brittleness, and poor bonding between the film and the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

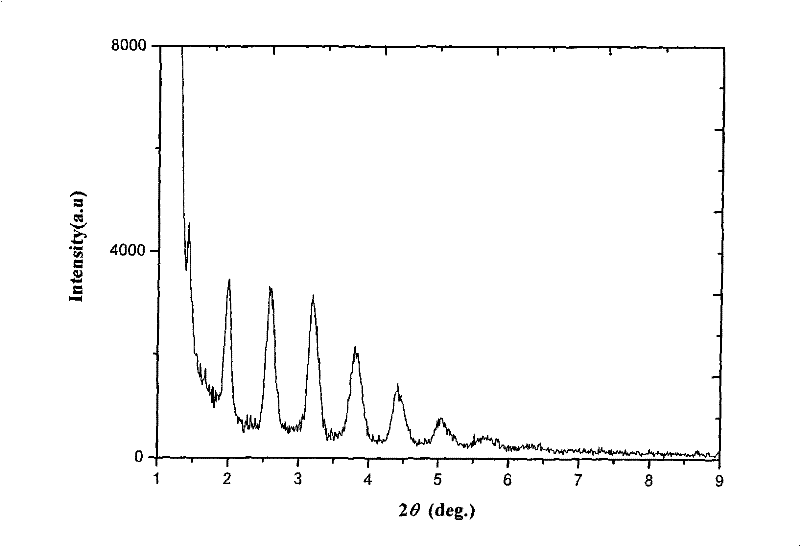

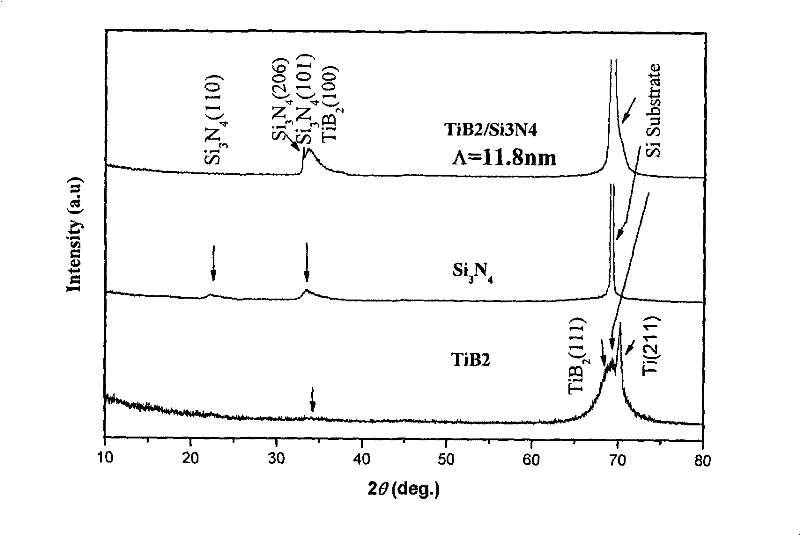

Image

Examples

Embodiment 1

[0077] Synthetic process parameters: Before the experiment, the Si wafer was ultrasonically cleaned with acetone and absolute alcohol for 15 minutes, dried and put into the ion beam assisted deposition coating chamber. The sputtering gas used in the deposition process is pure Ar 2 , use a mass flow controller to control the flow rate at 4.02 ml / s; background vacuum: 1.9×10-4Pa~2.0×10-4Pa, working pressure between 1.2×10-2Pa~1.3×10-2Pa; splash Sputtering ion source process parameters: discharge voltage 70V, acceleration voltage 200V, sputtering energy 1.05keV, sputtering beam current 25mA. with low energy Ar + When the ion gun is cleaned, its process parameters: discharge voltage 70V, acceleration voltage 100V, auxiliary energy 200eV, auxiliary beam current 5mA; substrate heating temperature: 25-425°C.

[0078] Preparation process: first deposit Ti as a transition layer on a single-sided polished Si(100) substrate, and then alternately deposit TiB 2 and Si 3 N 4 Do multi-l...

Embodiment 2

[0080] TiB 2 / Si 3 N 4 Synthesis of nano-multilayer films:

[0081] Control substrate heating temperature 225°C, modulation period 9nm, modulation ratio Si 3 N 4 :TiB 2 1:9 (equivalent to TiB 2 8.1nm thick, Si 3 N 4 The thickness of the transition layer is 0.9nm), the thickness of the transition layer is 30nm, the Ar gas flow is maintained at 4.02sccm; the sputtering energy is 1.05keV; the sputtering beam is 25mA, where TiB 2 and Si 3 N 4 The sputtering energy is 1.05keV; the sputtering beam current is 25mA; the heating current is 2-2.8A. The total working air pressure is 1.2-1.3×10 -2 Pa. There are 60 cycles between the two targets, and the computer program precisely controls TiB 2 with Si 3 N 4 The sputtering time is 300 seconds and 50 seconds. The total thickness of the film is about 450 nm. The film is in the high vacuum chamber, and the chamber is not opened until the temperature drops to room temperature. The preparation process is the same as in Examp...

Embodiment 3

[0083] TiB 2 / Si 3 N 4 Synthesis of nano-multilayer films:

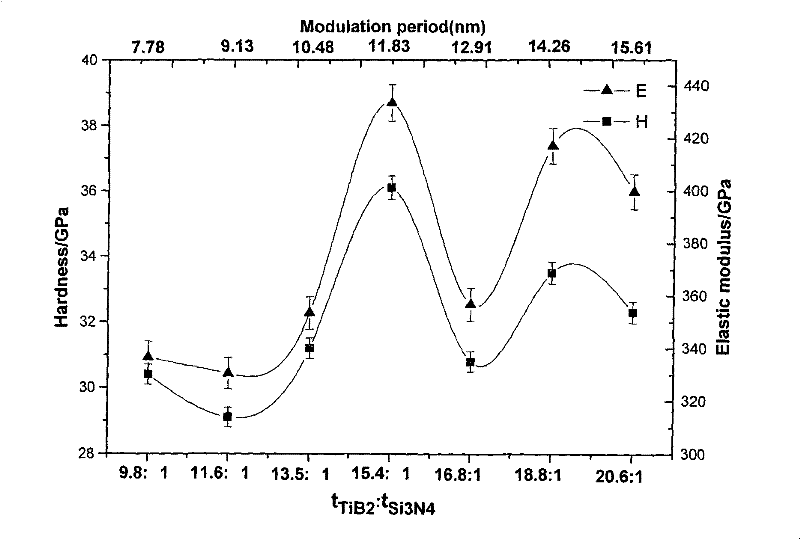

[0084] TiB 2 Thickness 11.21nm, Si 3 N 4 The thickness is 0.79nm, 11.8m (equivalent to the modulation ratio Si 3 N 4 :TiB 2 =1:15.6), the substrate temperature was kept at 225°C. There are 34-51 cycles between the two targets. The total working air pressure is 1.2-1.3×10 -2 Pa. Computer program precisely controls TiB 2 with Si 3 N 4 The sputtering time is 410 seconds and 40 seconds. where TiB 2 and Si 3 N 4 The sputtering energy is 1.05keV; the sputtering beam current is 25mA; the heating current is 2-2.8A. The total thickness of the film is about 600 nm. The film is in the high vacuum chamber, and the chamber is not opened until the temperature drops to room temperature to obtain TiB 2 / Si 3 N 4 Nano multilayer film. The preparation process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com