Biological tin/ag nano-multilayer film prepared by magnetron sputtering technology and its application

A nano-multi-layer and multi-layer film technology, which is applied in the field of bioengineering thin films and biomedical materials, can solve the problems that have not been found in the research of nano-multi-layer films, and achieve high hardness, high film-base binding force, and good biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

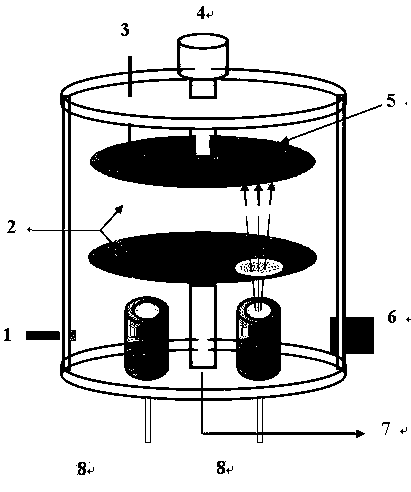

[0035] Synthesis of TiN / Ag nano-multilayer film by changing modulation ratio combined with substrate temperature conditions:

[0036] (1) Before the experiment, the titanium alloy (Ti6Al4V) substrate polished on one side was ultrasonically cleaned for 15 min with acetone and absolute alcohol in sequence, and then put into the magnetron sputtering coating chamber after drying.

[0037] (2) Vacuum the chamber so that the background vacuum in the chamber is 2.9×10 -4 Pa~3.0×10 -4 Pa.

[0038] (3) Adjust the flapper valve so that the working air pressure is 4 Pa, control the Ar intake flow rate with a mass flow meter to keep it at 40 sccm, turn on the bias power supply, adjust the base bias voltage to -400 V, and the current meter is normal , bombard and clean the sample with Ar ions for at least 15 min, and turn off the bias power.

[0039] (4) Turn on the radio frequency power supply, control the Ar intake flow rate with a mass flow meter to keep it at 40-41 sccm, adjust th...

Embodiment 2

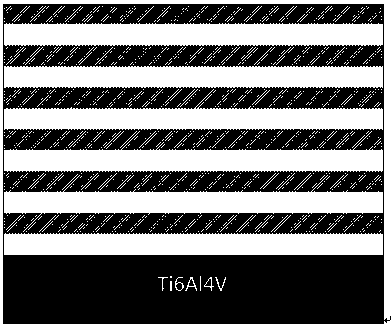

[0053] The application direction of biological TiN / Ag nano-multilayer film: intervertebral cage, dental implant and other biomedical materials.

[0054] As a biomedical material, such as an intervertebral fusion device, in the process of repairing the human spine, it must not only have a certain degree of compression resistance, but also need to take into account good tissue compatibility, non-toxicity, and minimize the content of the spine. Repulsion of osteoblasts and myocytes. The titanium alloy (Ti6Al4V) material has high hardness, wear resistance and good biocompatibility, so it has been widely used as a medical material. However, titanium alloy itself still has some limitations, biocompatibility needs to be further improved, and hardness and wear resistance can be further improved to meet the growing demand.

[0055] Using the magnetron sputtering (MS) method to deposit biological TiN / Ag nano-multilayer films on the surface of medical materials can not only improve the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com