Method for preparing plant pathomycete zymotic fluid produced by lactobacillus

A technology for phytopathogenicity and fermentation broth, applied in the biological field, can solve the problems such as unreported patents, and achieve the effects of simple process, low production cost, and high activity against phytopathogenic fungi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for preparing a lactobacillus-resistant phytopathogenic fungus fermentation liquid, the steps of the preparation method are:

[0025] (1) Preparation of seed fermentation liquid: After activating the Lactobacillus plantarum strain twice with MRS liquid medium, inoculate it in a 250ml Erlenmeyer flask, with a liquid volume of 100ml per bottle, and anaerobic culture at a constant temperature of 37°C for 24-48h to become Seed fermentation broth.

[0026] In this step, the composition of the MRS medium is: peptone 10g, beef extract 10g, yeast extract 5g, Tween-801ml, triammonium citrate 2g, K 2 HPO 4 2g, glucose 20g, sodium acetate 5g, MgSO 4 ·7H 2 O 0.1g, MnSO 4 0.05g, 1.0L water, the pH is 6.4-6.7.

[0027] (2) Preparation of fermented product: In a 7L fermenter equipped with 5L fermentation medium and a neutralizing agent for controlling the pH value of the fermented liquid, insert the above-mentioned seed fermented liquid according to the volume ratio of...

Embodiment 2

[0032] Only the static anaerobic cultivation at 37°C for 48 hours in step 2 was changed to static anaerobic cultivation at 39°C for 48 hours. Others are the same as in Example 1.

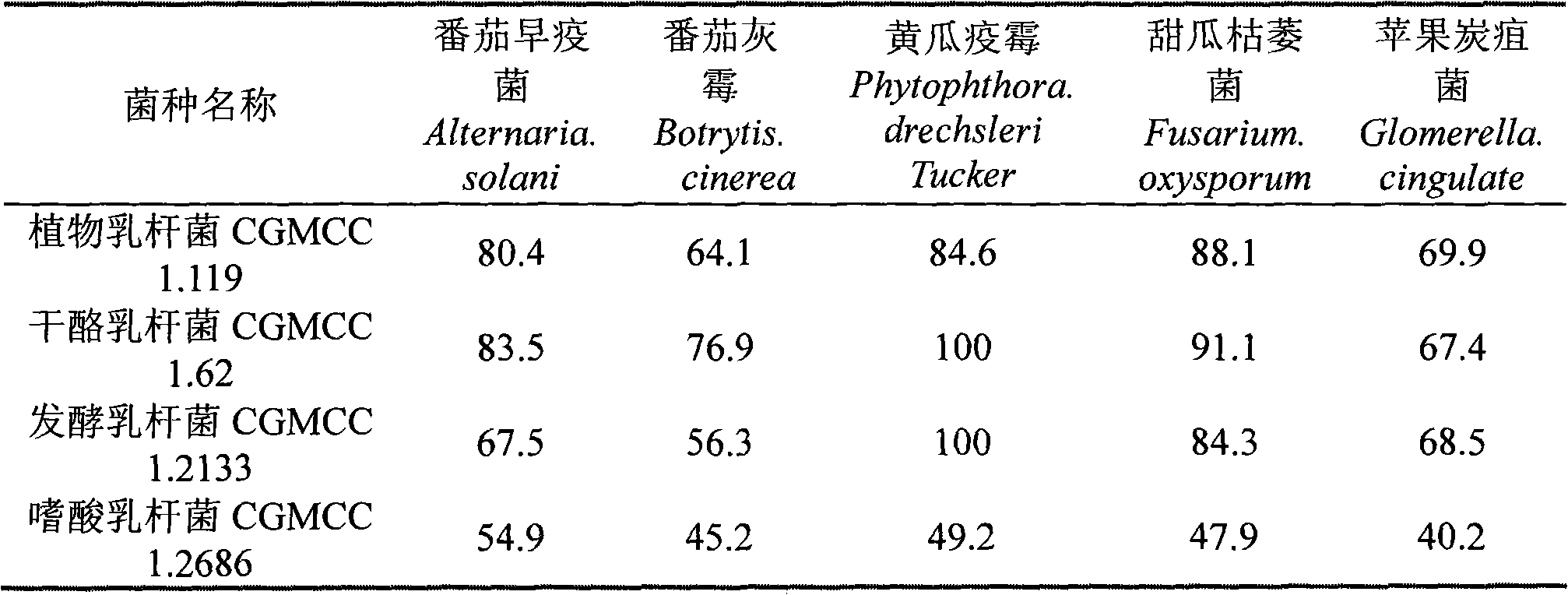

[0033] Four kinds of lactobacillus fermented liquids prepared by the preparation method of the present invention below carry out the in vitro antibacterial test (growth rate inhibition method) respectively:

[0034] (1) Centrifuge the fermented liquids of the four kinds of lactobacilli obtained at 14000 r / min and 4° C. for 10 min respectively, and collect the supernatants of the four kinds of lactobacilli respectively.

[0035] (2) Add 1ml of the above four supernatants to the melted 9ml PDA medium respectively, pour the obtained 10ml medium into a 9.0cm diameter sterilized petri dish, make a flat plate, and add sterile medium PDA was used as a control. From the edge of the phytopathogenic fungal colony cultivated for 3 to 6 days, use a puncher to cut into 5mm-diameter bacterial blocks, place them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com