Preparing method of ethanol-soluble resin for printing ink and application thereof

A technology of resin for ink and alcohol-soluble type, which is applied in the field of preparation of resin for alcohol-soluble ink, can solve the problems of poor applicability of non-polar substrates, unsatisfactory effect, increased raw material cost, etc. Overcome the effects of poor substrate adaptability, excellent adhesion fastness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

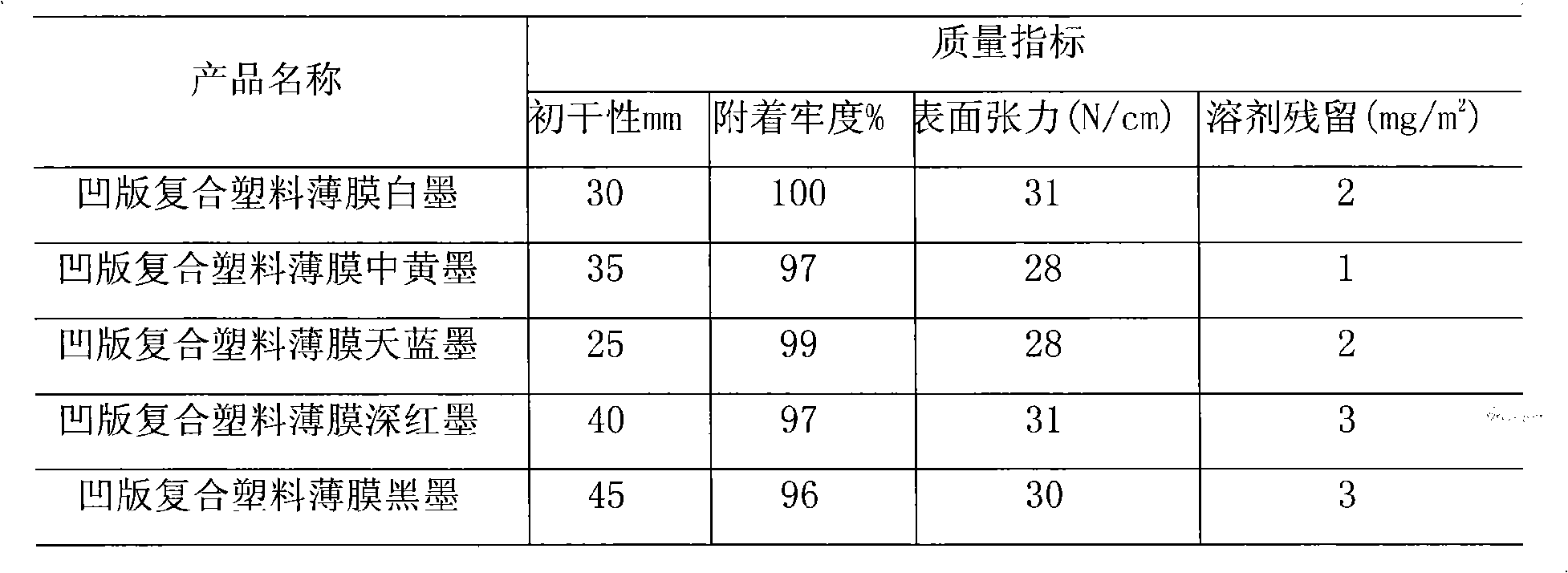

Image

Examples

Embodiment 1

[0018] This embodiment one provides a preparation method and application of a resin for alcohol-soluble ink, the preparation method of the resin is as follows:

[0019] Preparation of polyester diol:

[0020] a. Add 15-25 parts by mass of aliphatic dibasic acid, 15-25 parts by mass of aromatic dibasic acid, 25-35 parts by mass of crystalline dibasic alcohol and 20-30 parts by mass of amorphous dibasic alcohol In the polyester synthesis kettle, heat up to 200-240°C, and react for 5-6 hours to complete the esterification reaction; in practice, after the esterification reaction is completed, it is also possible to confirm whether the esterification reaction is qualified by measuring the acid value of the reactant. If the acid value of the reactant is less than or equal to 25mgKOH / g, it can be confirmed that the esterification reaction is qualified;

[0021] b. First pump down the vacuum to -0.02Mpa~-0.04Mpa, pay attention to observe the water outlet, keep the water output stable...

Embodiment 2

[0032] The present embodiment two provides a kind of preparation method of resin for alcohol-soluble ink, is used for manufacturing the resin that ink is used, and this method is specifically carried out according to the following steps:

[0033] (1) Preparation of polyester diol:

[0034] Get each raw material according to the following formula:

[0035] Raw material ratio%

[0036]Adipic acid 16

[0037] Isophthalic acid 21

[0038] Neopentyl glycol 29

[0039] Diethylene glycol 34

[0040] a. Add 16Kg of adipic acid, 21Kg of isophthalic acid, 29Kg of neopentyl glycol and 34Kg of diethylene glycol into the polyester synthesis kettle, heat up to 200-240°C, react for 5.5 hours, and wait for ester After the chemical reaction is completed, the measured acid value=18mgKOH / g;

[0041] b. Then perform low vacuum pumping, the vacuum degree of low vacuum pumping is -0.035Mpa, pay attention to observe the water outlet situation, keep the water output stable at 5kg / hour, after 1....

Embodiment 3

[0060] The present embodiment three provides a kind of preparation method of resin for alcohol-soluble ink, is used for manufacturing the resin that ink is used, and this method is specifically carried out according to the following steps:

[0061] (1) Preparation of polyester diol:

[0062] Get each raw material according to the following formula:

[0063] Raw material ratio%

[0064] Sebacic acid 18

[0065] Phthalic acid 20

[0066] 1,4 Butanediol 32

[0067] Propylene glycol 30

[0068] a. Add 18Kg of sebacic acid, 20Kg of phthalic acid, 32Kg of 1,4-butanediol and 30Kg of propylene glycol into the polyester synthesis kettle, heat up to 200-240°C, react for 6 hours, and wait for the esterification reaction to be completed. Measured acid value = 22mgKOH / g;

[0069] b. Preliminary low vacuum pumping, the vacuum degree of low vacuum pumping is -0.03Mpa, pay attention to observe the water outlet situation, keep the water output stable at 10kg / hour, after the low vacuum pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com