Informatization yarn tube for quality management of spun yarn

A quality management and bobbin technology, applied in the field of informationized bobbins, can solve the problems of disjointed spinning and winding management, no bobbin quality tracking management, etc.

Inactive Publication Date: 2009-09-09

JIANGNAN UNIV

View PDF0 Cites 28 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, my country's textile enterprises only conduct sampling tests on the bobbins produced by the spinning frame to determine whether the working conditions of the spinning frame are stable and whether management work such as preservation and maintenance is required. There is no specific inspection of the bobbins produced by each spindle. Quality Tracking Management

However, the current automatic winding machine can complete the statistical analysis of the quality of each bobbin. Therefore, there is a disconnection in management between spinning and winding

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

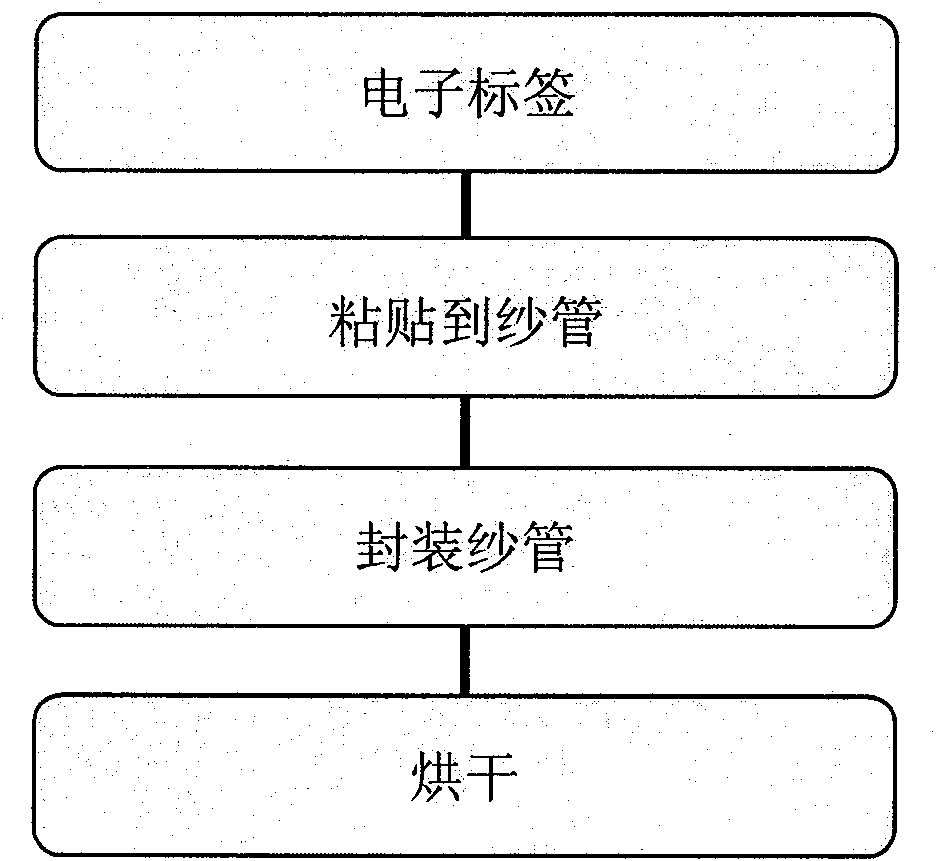

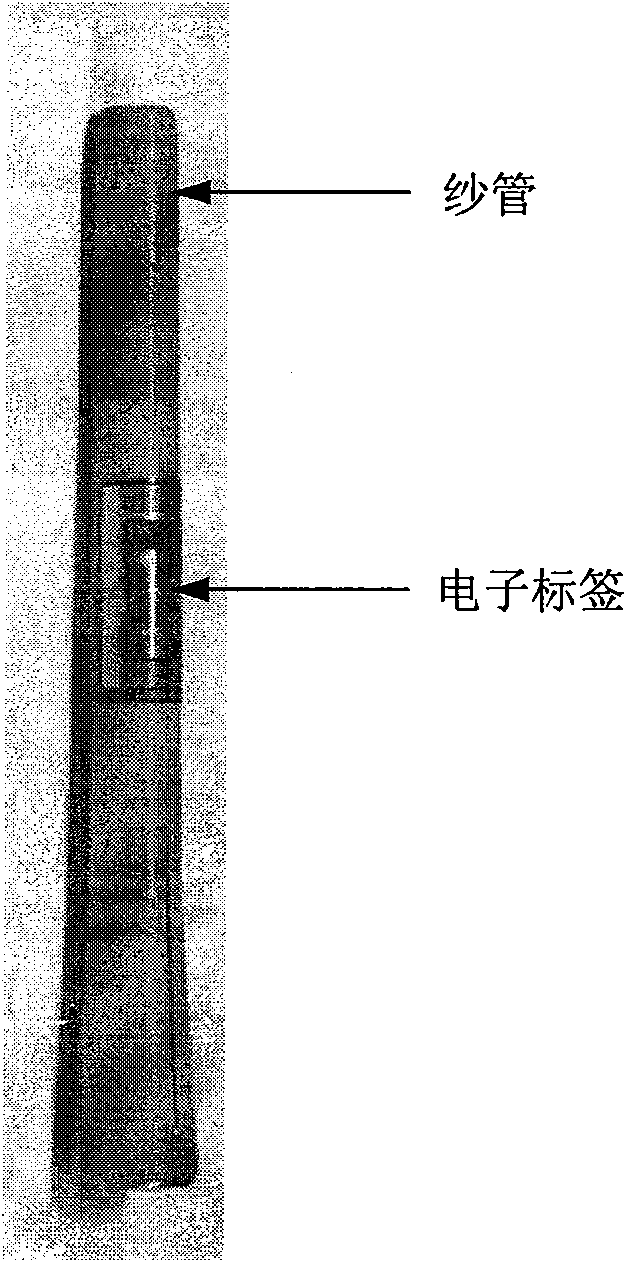

[0015] Choose the electronic label of the Philips chip; use 502 glue to paste the electronic label on the shell of the tube; use epoxy resin to encapsulate the tube; dry it at 40 degrees.

example 2

[0017] Select the electronic label of the TCL chip; use wood glue to paste the electronic label on the inner wall of the bobbin; use epoxy resin to encapsulate the bobbin; dry it at 40 degrees.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an informatization yarn tube for quality management of spun yarn, belonging to the field of novel textile machinery. Because a textile mill has many spinning machines and each spinning machine is provided with a plurality of spindles, which spindle of which spinning machine is each yarn tube from can not be analyzed in the subsequent spinning processes. In order to solve the technical problem, the invention adopts a means of sticking radio frequency identities (RFID) on each yarn tube as the unique identification mark of each yarn tube, and the information of the spindles installed on each yarn tube in the production process of spun yarn is recorded to provide the basis for subsequently checking the spindle at which the yarn tube is positioned. The informatization yarn tube is used for quality tracking of a single spindle of spinning machines, and is used for quality tracing of defective yarn tubes.

Description

technical field [0001] The invention relates to an informationized bobbin with a special structure for spun yarn quality management, in particular to a method for storing and reading bobbin information by using an electronic tag, so as to achieve the purpose of spun yarn quality management. Background technique [0002] At present, my country's textile enterprises only conduct sampling tests on the bobbins produced by the spinning frame to determine whether the working conditions of the spinning frame are stable and whether management work such as preservation and maintenance is required. There is no specific inspection of the bobbins produced by each spindle. Quality tracking management. However, the current automatic winding machine can complete the statistical analysis of the quality of each bobbin. Therefore, there is a disconnection in management between spinning and winding. [0003] The electronic tag technology is a non-contact automatic identification technology tha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65H75/08B65H75/18

Inventor 刘基宏王鸿博高卫东江红霞卢雨正

Owner JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com