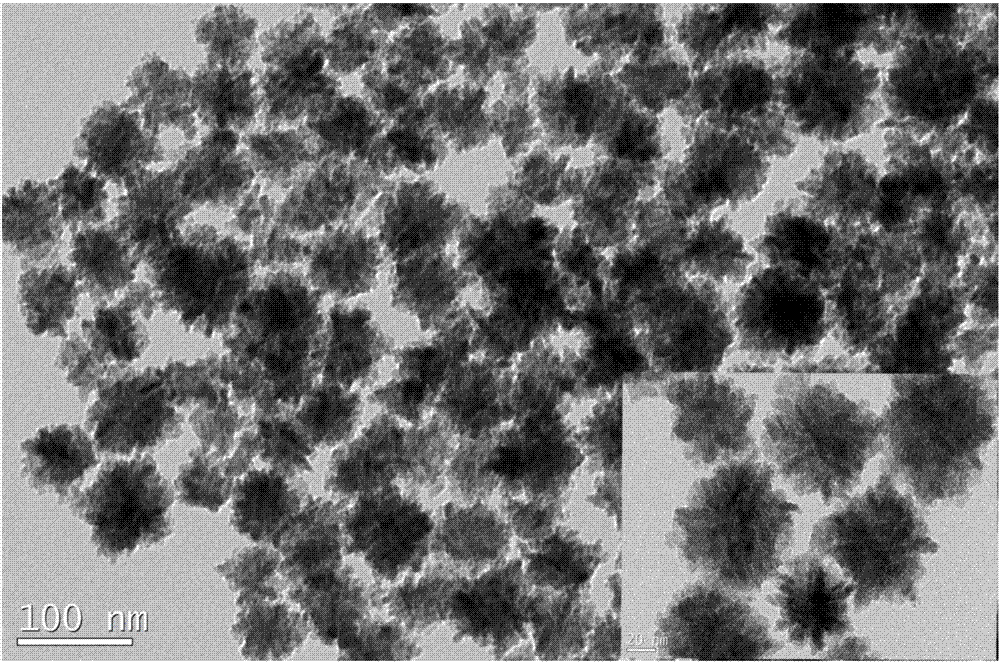

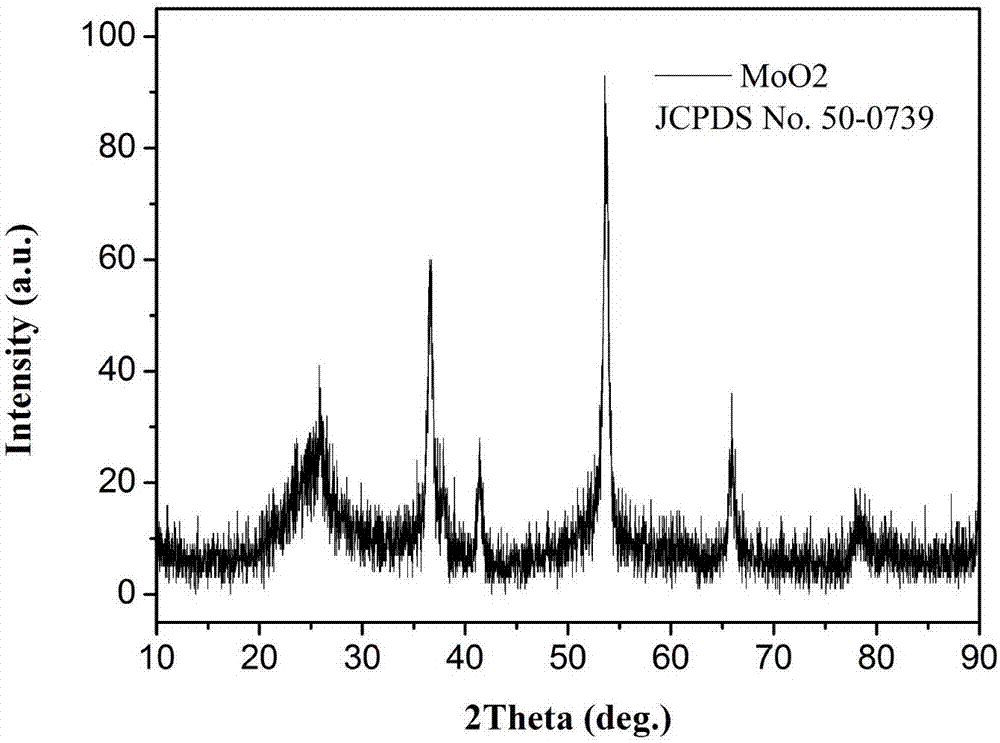

Preparation method of flower shape molybdenum dioxide nano powder

A technology of nano-powder and molybdenum dioxide, which is applied in the field of preparation of flower-like molybdenum dioxide nano-powder, achieving the effects of low cost, uniform size and good monodispersity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A flower-like MoO 2 The preparation method of nanopowder, comprises the steps:

[0022] Add 3M molybdenum powder to a clean 100mL beaker, then add 2.0mL of H 2 O, until the dispersion is uniform, add 2.0mL of H 2 o 2 , after the reaction is finished, seal it with plastic wrap, and let it stand overnight for 24 hours. Then add the molybdic acid precursor solution obtained above to 20mL of absolute ethanol, stir evenly, transfer to 50mL polytetrafluoroethylene liner, and put it into a 50mL stainless steel jacket, and conduct a hydrothermal reaction at 180°C for 8h. Then it was naturally cooled to room temperature, the obtained product was centrifuged and washed several times with water and absolute ethanol, and the obtained sample was dried at 60° C. for 12 hours.

Embodiment 2

[0024] Add 3M molybdenum powder to a clean 100mL beaker, then add 2.0mL of H 2 O, until the dispersion is uniform, add 1.0mL of H 2 o 2 , after the reaction is finished, seal it with plastic wrap, and let it stand overnight for 24 hours. Then add 8 mL of absolute ethanol to the molybdic acid precursor solution obtained above, stir evenly, transfer to 50 mL polytetrafluoroethylene lining, and put it into a 50 mL stainless steel jacket, and conduct a hydrothermal reaction at 180°C for 8 hours. Then it was naturally cooled to room temperature, the obtained product was centrifuged and washed several times with water and absolute ethanol, and the obtained sample was dried overnight at 60°C.

Embodiment 3

[0026] Add 3M molybdenum powder (550nm) to a clean 100mL beaker, then add 2.0mL of H 2 O, until the dispersion is uniform, add 1.0mL of H 2 o 2 , after the reaction is finished, seal it with plastic wrap, and let it stand overnight for 24 hours. Then add the molybdic acid precursor solution obtained above to 20mL of absolute ethanol, stir evenly, transfer to 50mL polytetrafluoroethylene liner, and put it into a 50mL stainless steel jacket, and conduct a hydrothermal reaction at 180°C for 8h. Then it was naturally cooled to room temperature, the obtained product was centrifuged and washed several times with water and absolute ethanol, and the obtained sample was dried at 60° C. for 12 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com