Device and method for recycling volatile substances by utilizing adsorbent bed

A technology for volatile substances and adsorption beds, applied in separation methods, chemical instruments and methods, filter regeneration, etc., can solve the problems of failure to further improve efficiency, reduce the adsorption function of the adsorption bed 1, and waste the environment of volatile substances, etc. problems, to achieve the effect of reducing waste, improving adsorption effect and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

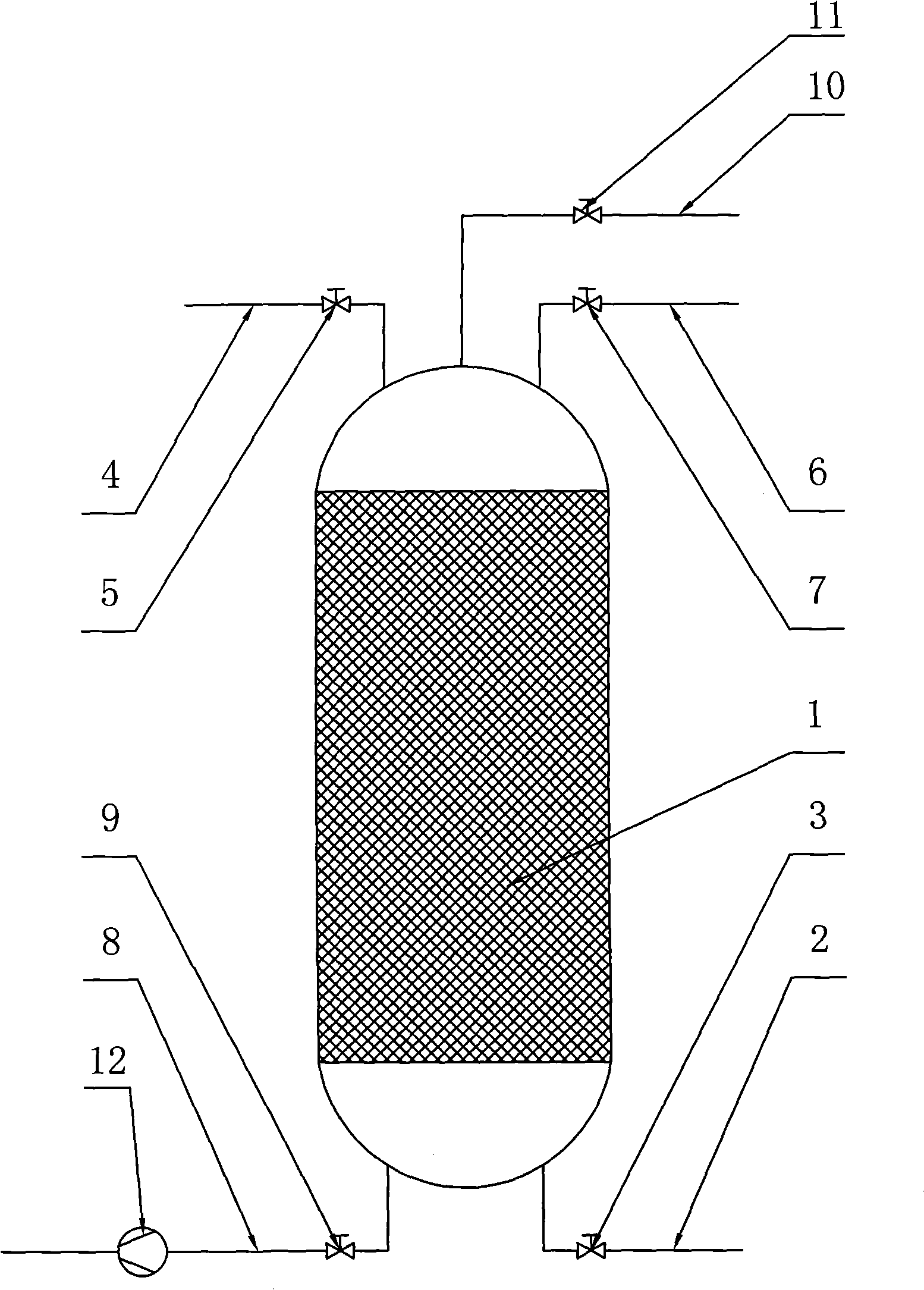

[0044] The method for recovering dichloromethane with an adsorption bed of the present invention includes the following two steps:

[0045] (1) In the adsorption step, open the intake valve 3 and the exhaust valve 5; close the steam valve 7 and the desorption valve 9;

[0046] (2) In the desorption step, open the steam valve 7 and the desorption valve 9; close the intake valve 3 and the exhaust valve 5.

[0047] The process of the desorption step is carried out according to the following method:

[0048] Open the steam valve 7, open the desorption valve 9, and use steam to heat the adsorption bed 1 with a delay of more than 1 minute. When the temperature of the mixed gas injection end of the adsorption bed 1 reaches or exceeds 39.8°C, turn off the steam Valve 7, open the power intake valve 11, delay more than 20 seconds, close the power intake valve 11, then close the desorption valve 9, then open the exhaust valve 5, open the intake valve 3 to enter The adsorption step.

Embodiment 2

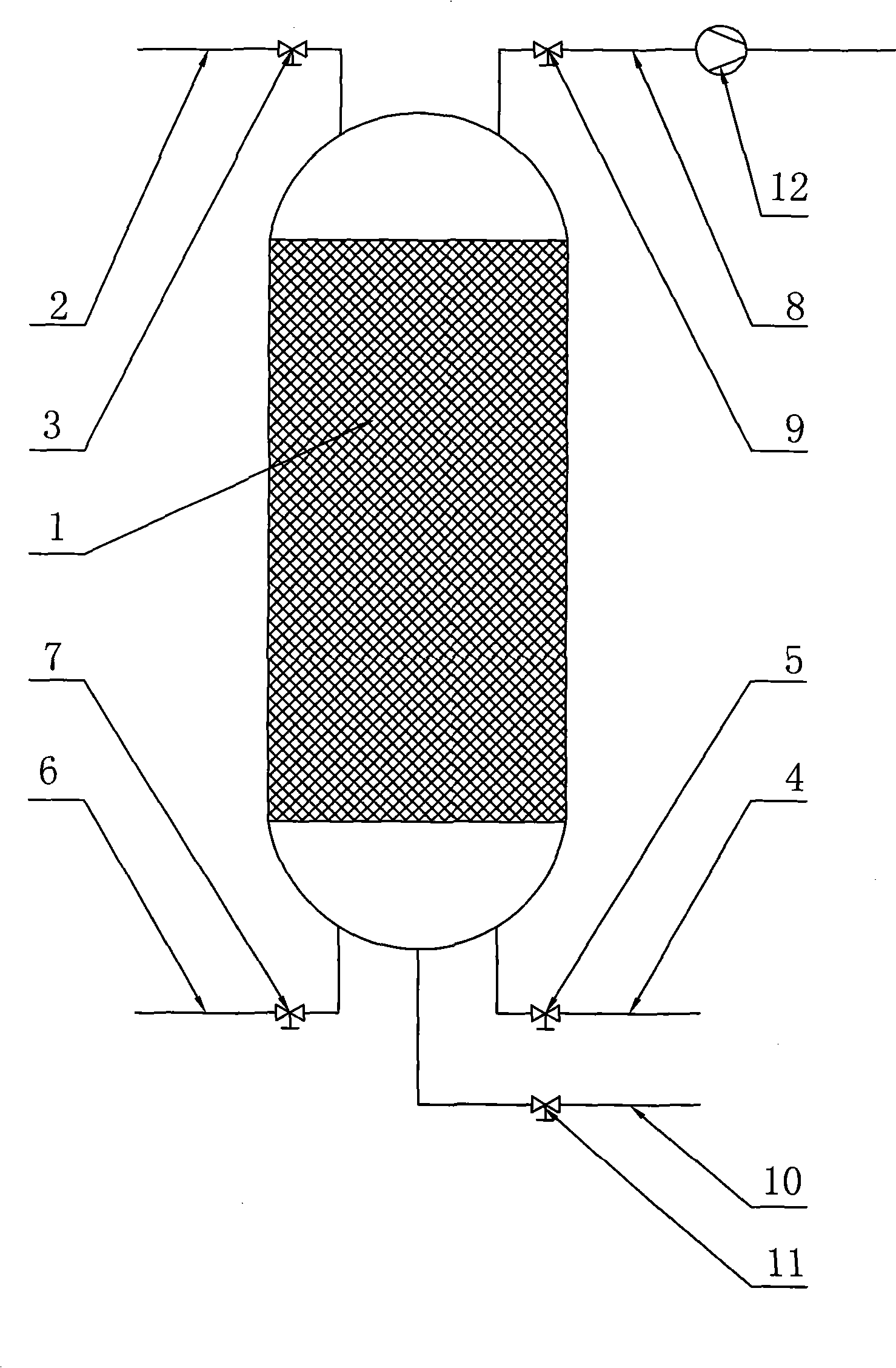

[0050] The method for recovering dichloromethane with an adsorption bed of the present invention includes the following two steps:

[0051] (1) In the adsorption step, open the intake valve 3 and the exhaust valve 5; close the steam valve 7 and the desorption valve 9;

[0052] (2) In the desorption step, open the steam valve 7 and the desorption valve 9; close the intake valve 3 and the exhaust valve 5.

[0053] The process of the desorption step is carried out according to the following method:

[0054] Open the steam valve 7, open the desorption valve 9, heat the adsorption bed 1 with steam, delay for more than 1 minute, and close the steam valve 7 when the temperature of the mixed gas injection end of the adsorption bed 1 reaches or exceeds 39.8°C , Open the power intake valve 11, delay more than 20 seconds, close the power intake valve 11, start the gas suction device 12, delay more than 20 seconds, stop the gas suction device 12, and then close The desorption valve 9 then ope...

Embodiment 3

[0056] The method for recovering dichloromethane with an adsorption bed of the present invention includes the following two steps:

[0057] (1) In the adsorption step, open the intake valve 3 and the exhaust valve 5; close the steam valve 7 and the desorption valve 9;

[0058] (2) In the desorption step, open the steam valve 7 and the desorption valve 9; close the intake valve 3 and the exhaust valve 5.

[0059] The process of the desorption step is carried out according to the following method:

[0060] Open the steam valve 7, open the desorption valve 9, heat the adsorption bed 1 with steam, delay more than 1 minute, when the temperature of the mixed gas injection end of the adsorption bed 1 reaches or exceeds 39.8°C, open the power intake Valve 11, delay more than 20 seconds, close the steam valve 7, delay more than 20 seconds, close the power intake valve 11, then close the desorption valve 9, then open the exhaust valve 5, open the intake Valve 3 enters the adsorption step.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com