Firework bright bead and manufacture technology thereof

A production process and bright bead technology, applied in the field of fireworks industry, can solve the problems of short discharge time, unsafe factors, friction explosion, etc., and achieve the effects of prolonged burning time, high safety factor and simple production conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

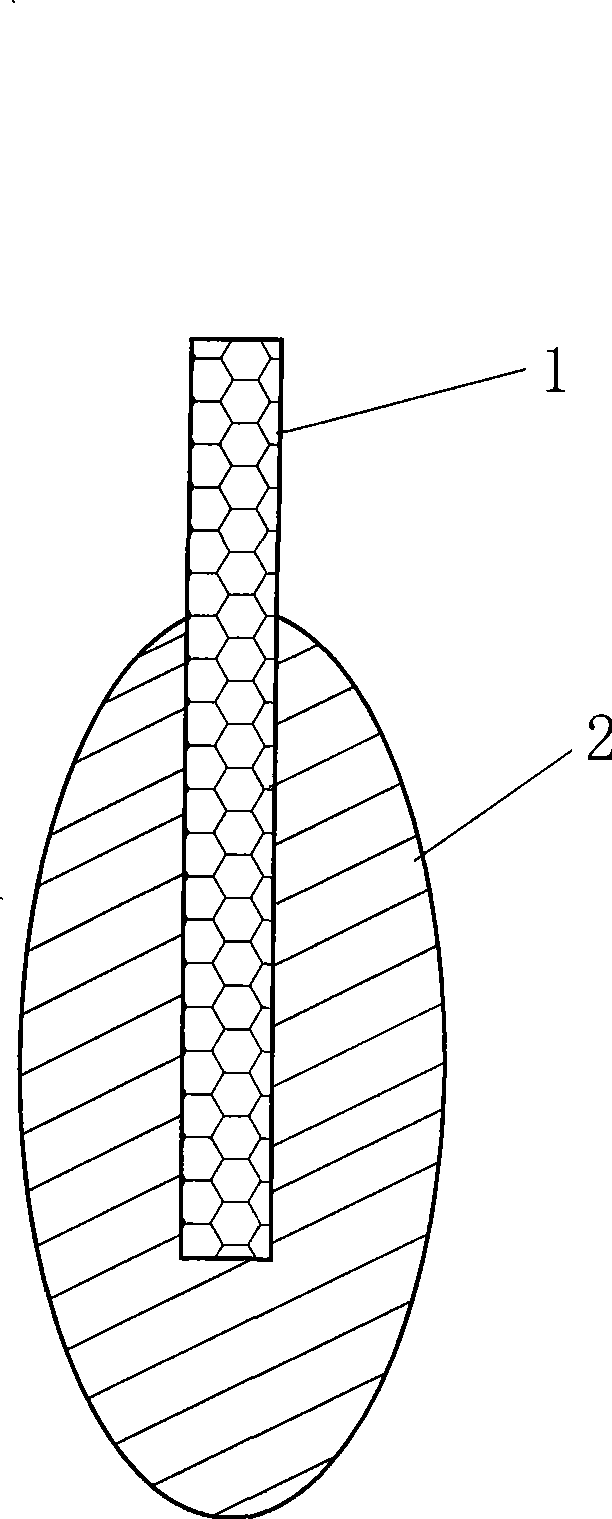

[0012] Embodiment 1. A fireworks bright bead and its production process. After a section of lead wire 1 is wetted with light and color agent 2, it is properly dried, and then the above steps are repeated until the size of the bright bead meets the requirements, and the shape can be cylindrical or gourd. shape.

Embodiment 2

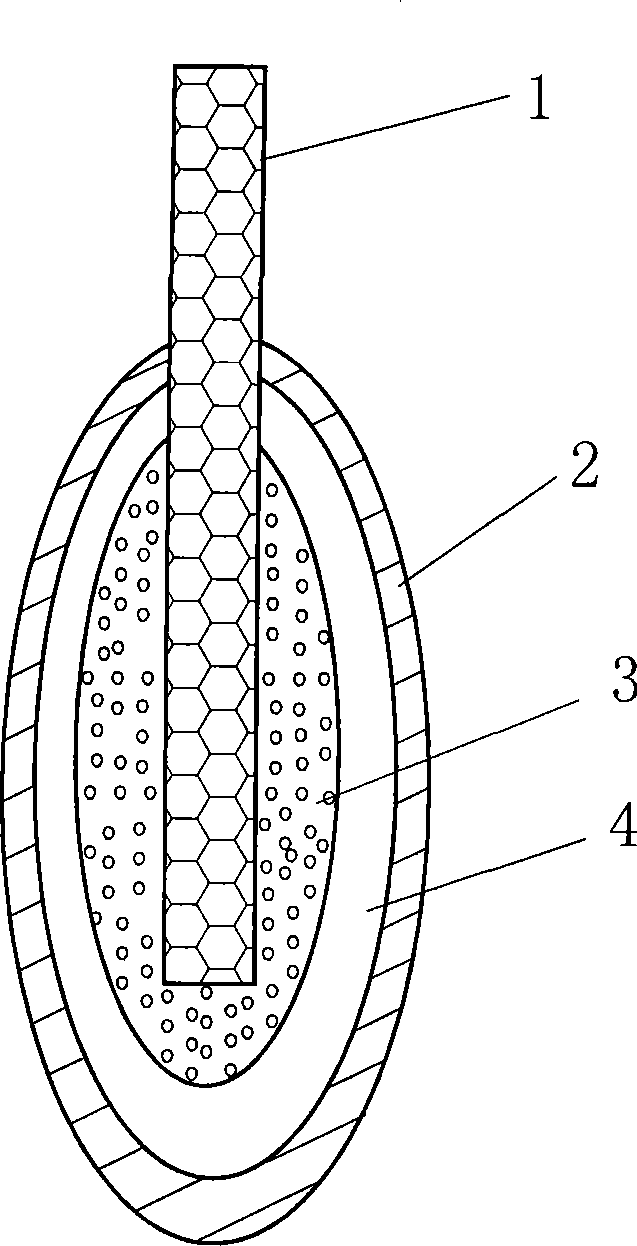

[0013] Embodiment 2, as an improvement of the present invention, one or more wet special effect medicines 3 are first adhered to one end of a section of lead wire 1 and then properly dried, and then wet encrusting medicines are adhered to the surface of special effect medicines 3 in turn 4. Harmonize the light and color medicine 2 and dry it properly to make the bright beads into a cylindrical or gourd shape of a certain size. The purpose of using encrusting medicine 4 is to form a cylindrical shell. When the bright beads burn, the special effect medicine 3 in the cylindrical shell will emit special effects such as flute sound, rotation or spray flowers when burning in the air. The special effect medicine 3 can be a whistle Tone medicine, rotation medicine or other special effect medicine.

[0014] In the above embodiments, special tools are used to operate in batches, which can improve production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com