Creep-resistant steel

A creep-resistant steel, the most advanced technology, applied in the field of creep-resistant steel, can solve the problem of reducing toughness, and achieve the effect of high fatigue strength and good toughness characteristics

Active Publication Date: 2013-07-17

ANSALDO ENERGIA SWITZERLAND AG

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

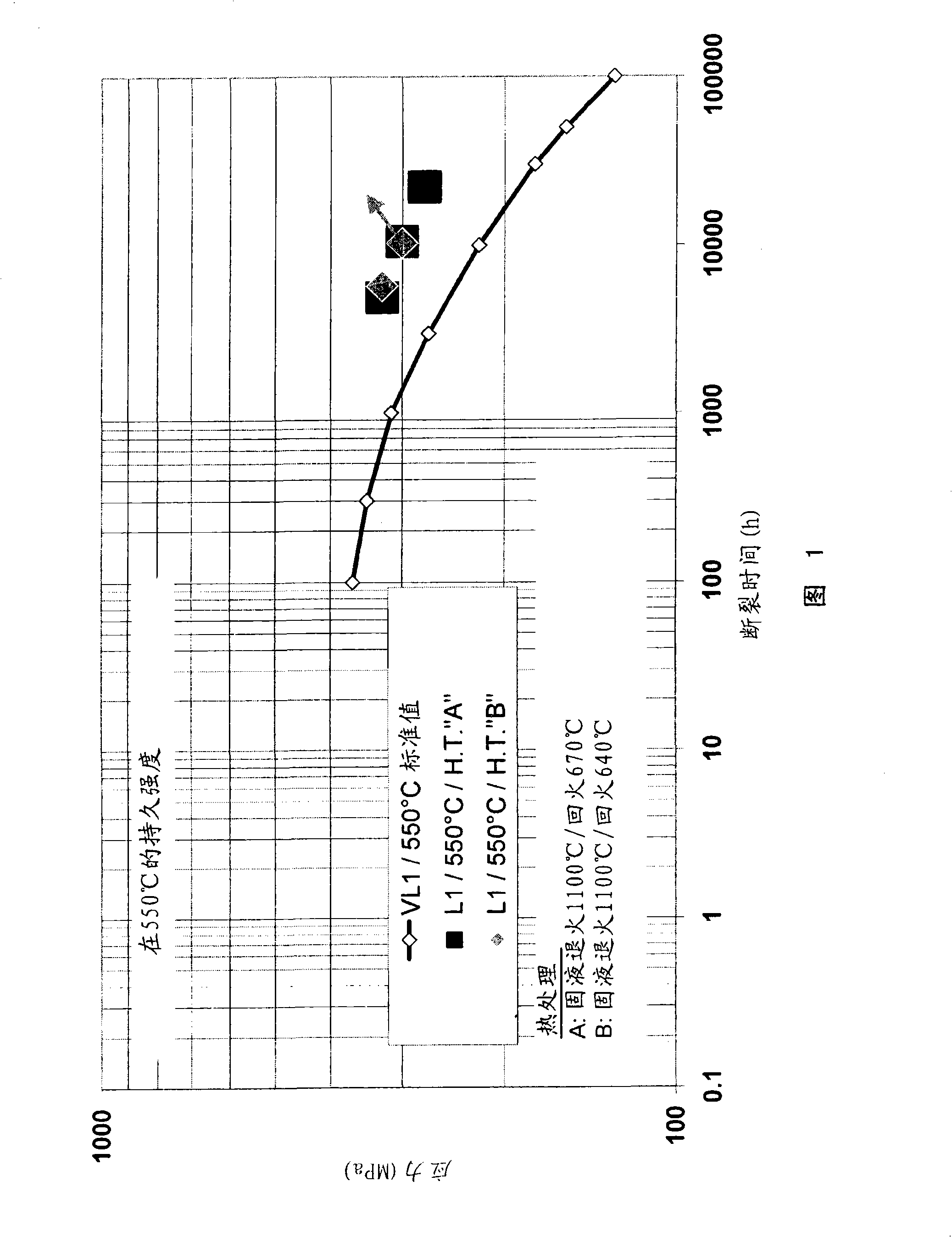

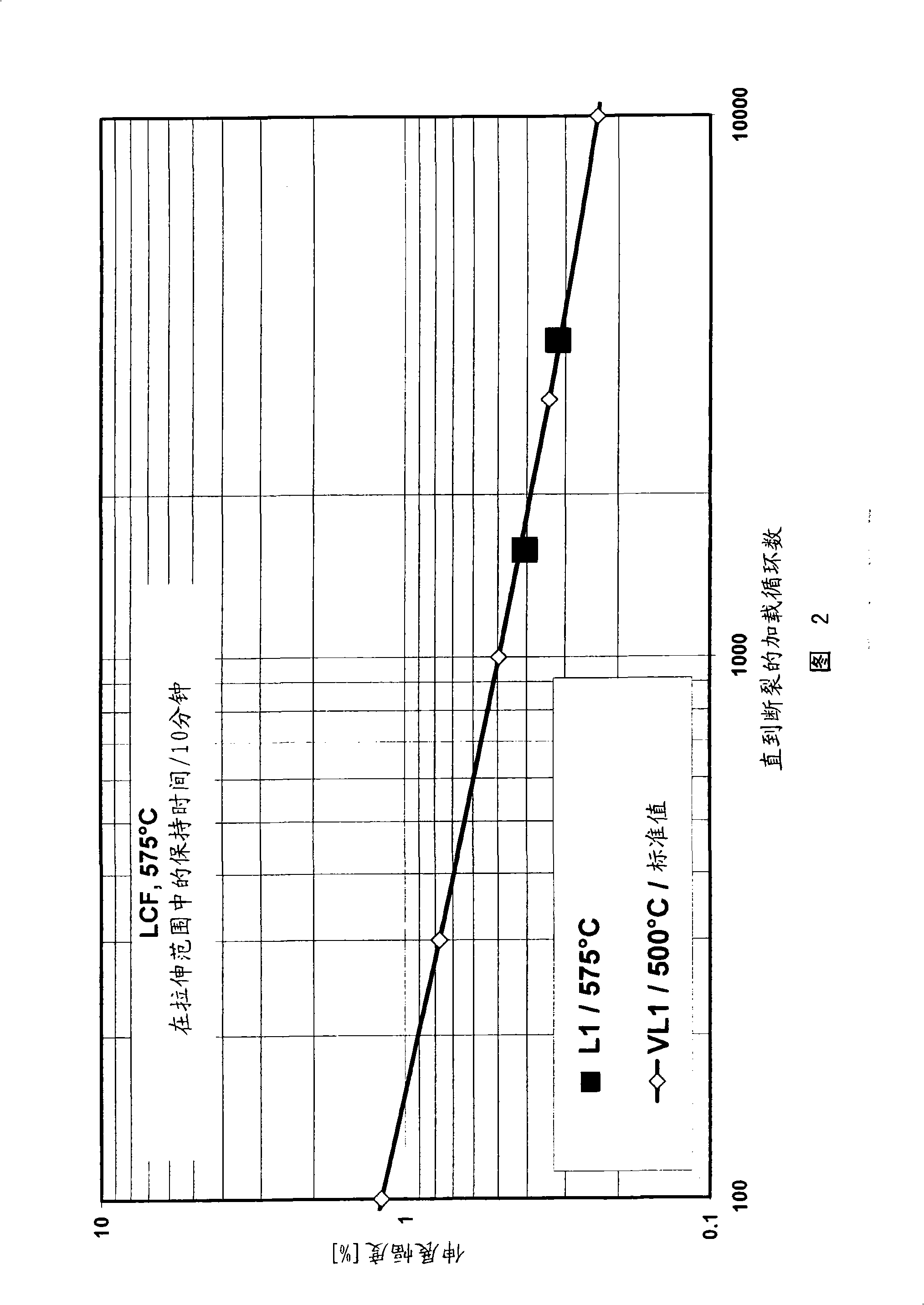

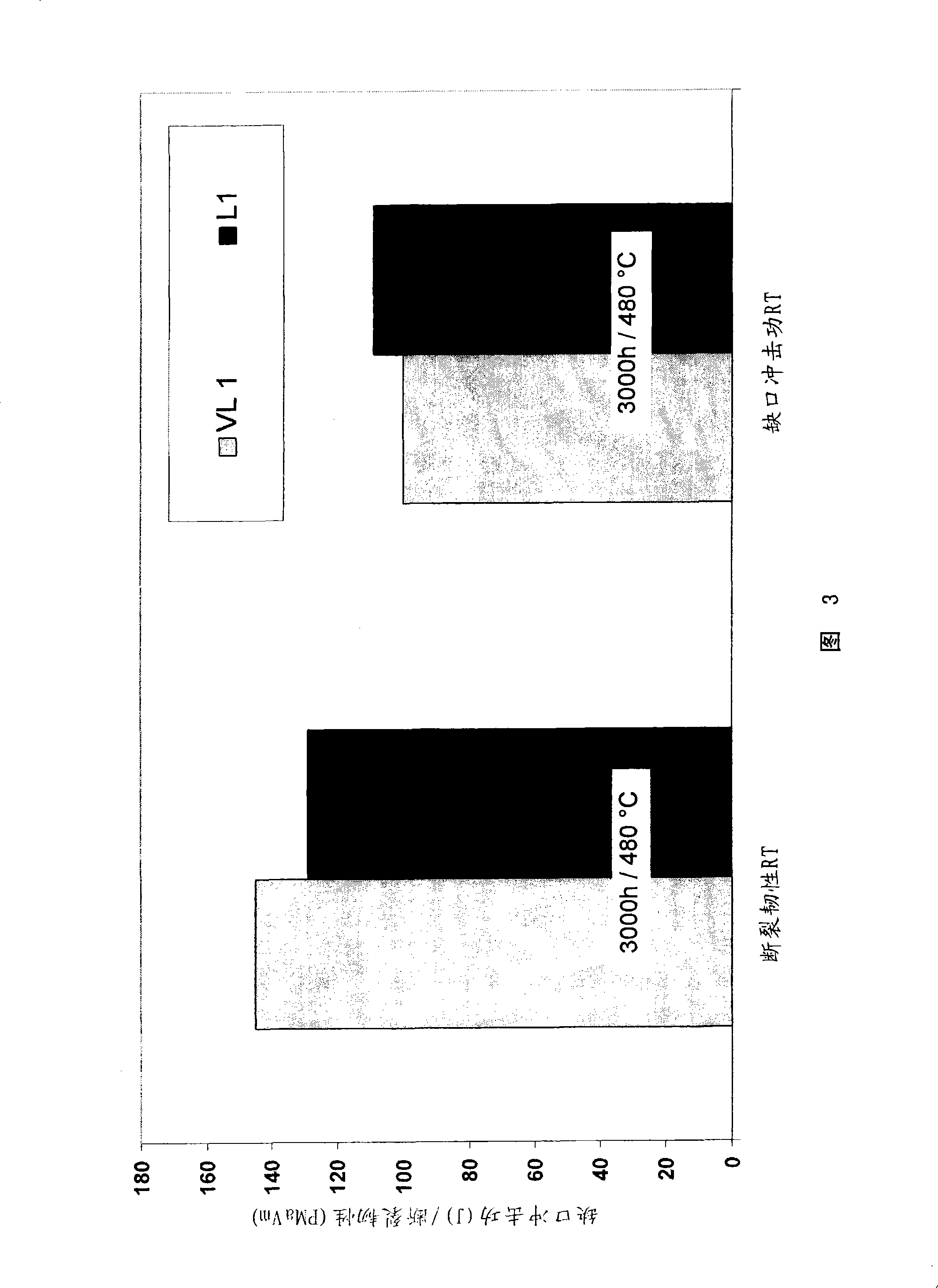

[0054] The invention is explained in more detail below with the aid of an exemplary embodiment and FIGS. 1 to 3 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A creep-resistant steel comprises carbon (in wt.%) (0.l0-0.15), chromium (8-13), manganese (0.1-0.5), nickel (2-3), molybdenum and / or tungsten (0.5-2) when both elements are present, a maximum total of (3), niobium (0.02-0.2), tantalum (0.05-2), vanadium (0.1-0.4), palladium (0.005-2), nitrogen (0.02-0.08), silicon (0.03-0.15), boron (80-120), maximum about 100 ppm of aluminum, maximum about 150 ppm of phosphorous, maximum about 250 ppm of arsenic, maximum about 120 ppm of tin, maximum about 30 ppm of antimony, maximum about 50 ppm of sulfur, and remaining iron and unavoidable impurities.

Description

technical field [0001] The invention relates to a steel based on 8-13% chromium, which are used for rotors in the field of power generation. The present invention involves the selection and content determination of specific alloying elements capable of establishing exceptionally good creep resistance in such materials at temperatures of 550°C and above. The steel according to the invention can also have good fatigue resistance at low loading cycles (LCF=Low Cycle Fatigue) and good toughness after long-term aging, so that it can be used not only in gas turbines but also in steam turbines use. Background technique [0002] Martensitic hardening steel based on 9-12% chromium is a widely used material in the field of power generation. They have been developed for use in steam generators operating at temperatures above 600°C and steam pressures of 250 bar to increase generator efficiency. The creep and oxidation resistance of the material under these operating conditions is of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/60C22C38/54C22C38/48C22C38/46C22C38/44

CPCC22C38/44

Inventor M·纳兹米A·库恩兹勒M·斯陶布利

Owner ANSALDO ENERGIA SWITZERLAND AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com