Method for preparing platinum electrode of dye sensitized solar cell

A technology of solar cells and dye sensitization, applied in capacitor electrodes, photosensitive devices, circuits, etc., can solve the problems of poor batch performance repeatability, uneven surface resistance of platinum electrodes, etc., to improve photoelectric conversion efficiency, uniform surface resistance, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

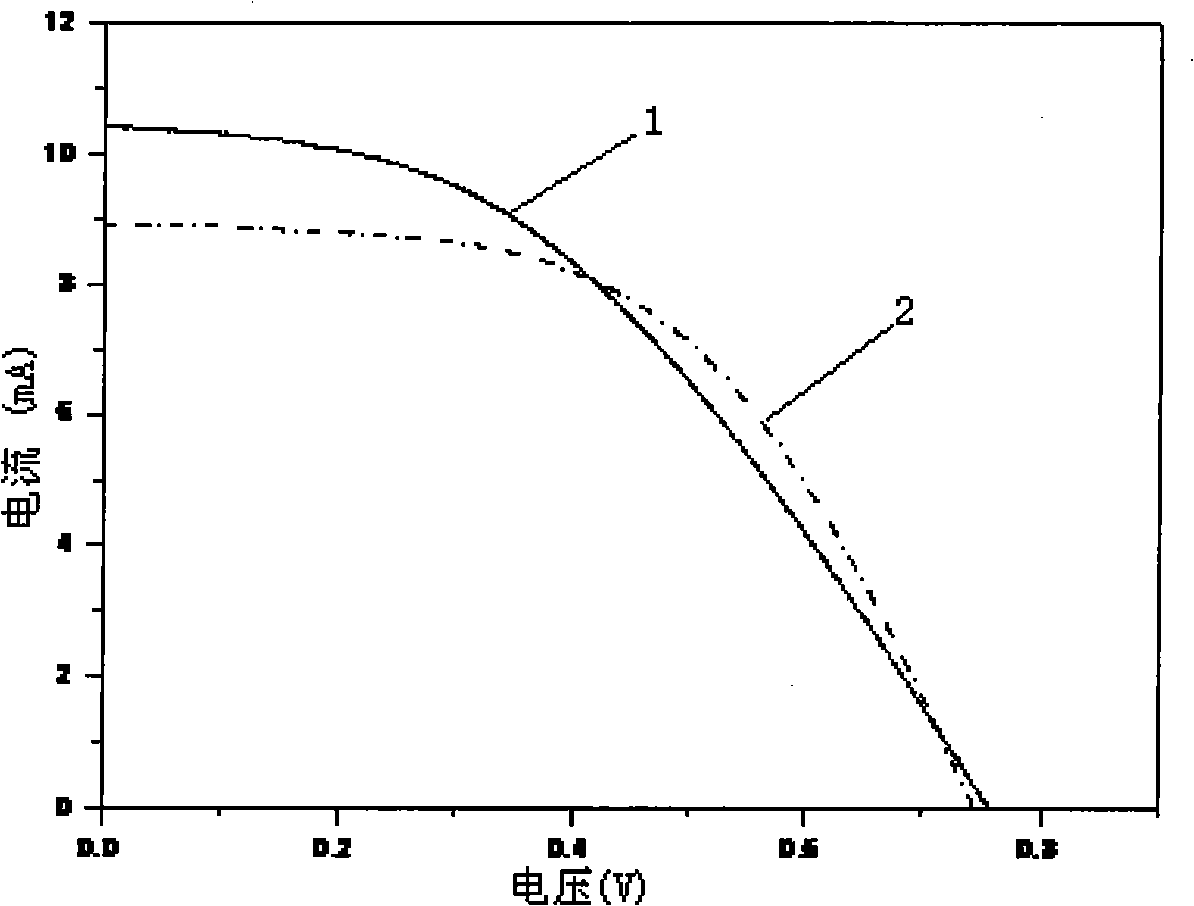

Image

Examples

Embodiment 1

[0013] The preparation method of dye-sensitized solar cell platinum electrode according to claim 1, comprises the steps:

[0014] 1) Soak and clean the large-area transparent conductive glass substrate in an ultrasonic cleaner with distilled water, analytically pure absolute ethanol or analytically pure acetone for 15 minutes, and then dry it for later use.

[0015] 2) Under heating and stirring in a water bath at 60°C, slowly add 10 g of ethyl cellulose to the terpineol liquid at a mass percentage ratio of 1:9, and mix and stir for 2 hours to form an organic vehicle with a viscosity of 5.7 Cp;

[0016] 3) 1.0g analytically pure chloroplatinic acid is pre-dissolved in 10g of terpineol liquid, then added to 89g of the organic carrier of the above step 2), and stirred evenly to form a chloroplatinic acid slurry with a viscosity of 5.8Cp. The percentage range of chloroplatinic acid in the platinum acid slurry is 1.0%;

[0017] 4) Screen printing: use the screen printing coating ...

Embodiment 2

[0020] The preparation method of dye-sensitized solar cell platinum electrode according to claim 1, comprises the steps:

[0021] 1) Soak and clean the large-area flexible substrate in an ultrasonic cleaner with distilled water, analytically pure absolute ethanol or analytically pure acetone for 15 minutes, and then dry it for later use.

[0022] 2) Under heating and stirring in a water bath at 60°C, slowly add 30 g of ethyl cellulose into the terpineol liquid at a mass percentage ratio of 1:7, and mix and stir for 2 hours to form an organic vehicle with a viscosity of 5.8 Cp;

[0023] 3) 1.0g analytically pure chloroplatinic acid is pre-dissolved in 10g of terpineol liquid, then added to 189g of the organic carrier of the above step 2), and stirred evenly to form a chloroplatinic acid slurry with a viscosity of 5.9Cp. The percentage range of chloroplatinic acid in the platinum acid slurry is 0.5%;

[0024] 4) Screen printing: use the screen printing coating process, use a 30...

Embodiment 3

[0027] The preparation method of dye-sensitized solar cell platinum electrode according to claim 1, comprises the steps:

[0028] 1) Soak and clean the large-area transparent conductive glass substrate in an ultrasonic cleaner with distilled water, analytically pure absolute ethanol or analytically pure acetone for 15 minutes, and then dry it for later use.

[0029] 2) Under heating and stirring in a water bath at 60°C, slowly add 200 g of ethyl cellulose into the terpineol liquid at a mass percentage ratio of 1:5, and mix and stir for 2 hours to form an organic vehicle with a viscosity of 5.9 Cp;

[0030] 3) 1.0g analytically pure chloroplatinic acid is pre-dissolved in 10g of terpineol liquid, then added to 989g of the organic carrier of the above step 2), and stirred evenly to form a chloroplatinic acid slurry with a viscosity of 6.0Cp, chlorine The percentage range of chloroplatinic acid in the platinum acid slurry is 0.1%;

[0031] 4) Screen printing: use the screen prin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com