Method and device for manufacturing black silicon battery

A manufacturing method and a technology for manufacturing a device are applied in the field of the manufacturing method and device of a black silicon battery, and can solve the problems of difficulty in improving the uniformity of diffusion resistance and conversion efficiency, difficult to control the uniformity of the SiO2 layer, and difficult to control the uniformity of the gas. , to achieve the effect of improving electrical properties, uniform surface resistance and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] As mentioned in the background technology section, in the current solar cell production process, it is difficult to control the uniformity of the gas due to the long diffusion furnace tube, and there are differences in the oxidation time of the silicon wafer in the furnace, so the SiO formed by the oxidation of the silicon wafer 2 The uniformity of the layer is also difficult to control, so it is difficult to improve the uniformity of the diffusion resistance and the conversion efficiency.

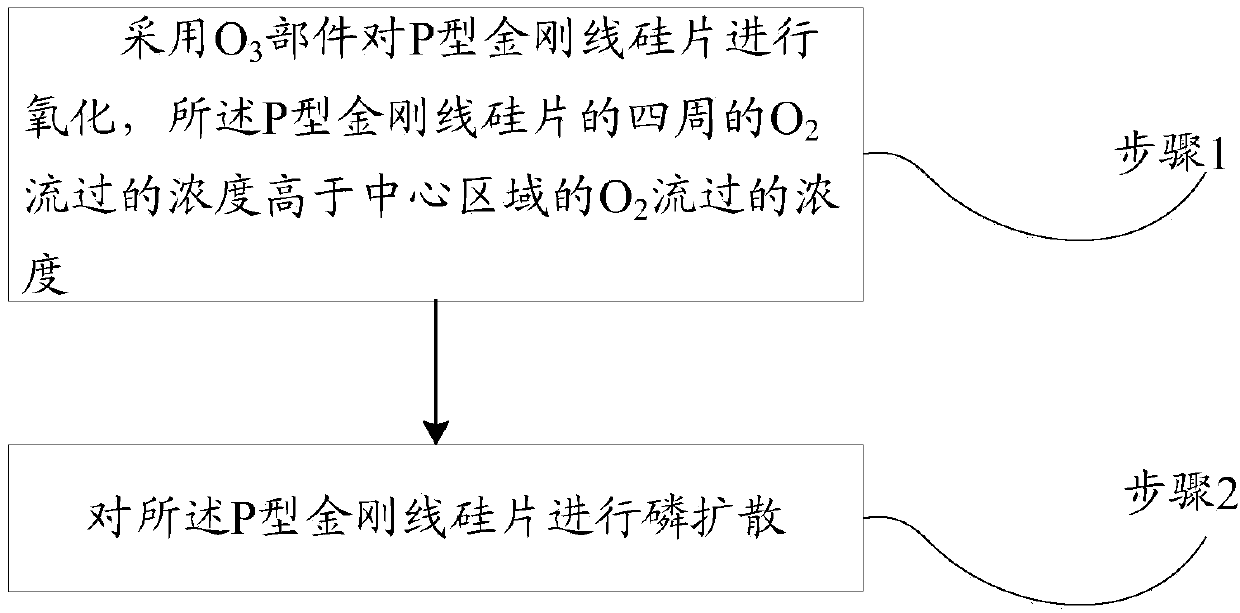

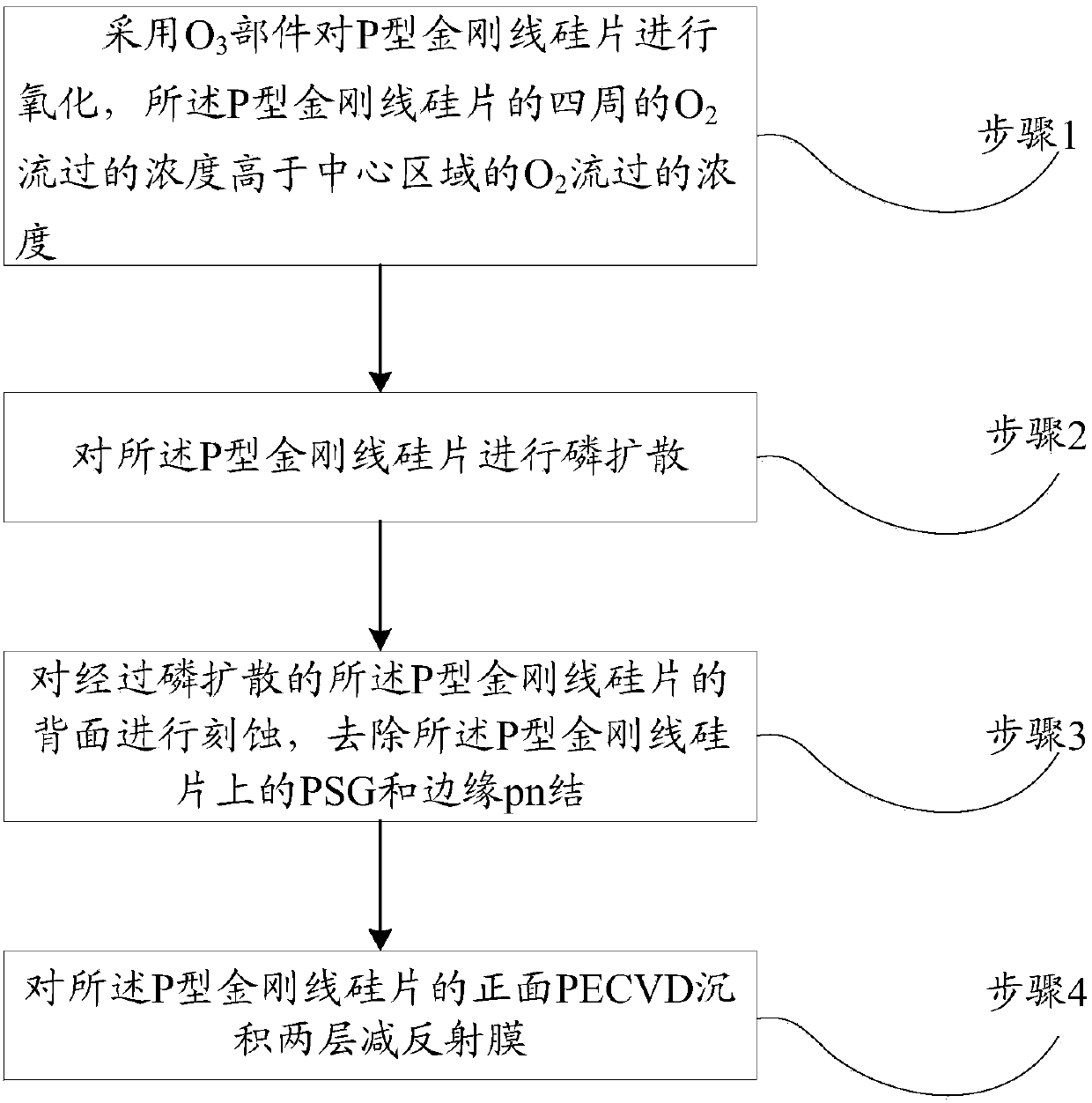

[0039] Based on this, an embodiment of the present invention provides a method for manufacturing a black silicon battery, including:

[0040] Step 1, using O3 components to oxidize the P-type diamond wire silicon wafer, the O around the P-type diamond wire silicon wafer 2 The concentration of flow-through is higher than that of O in the central region 2 flow through concentration;

[0041] Step 2, performing phosphorus diffusion on the P-type diamond wire silicon wafer;

[0042] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com