Device and method for inner bore type component brush plating

A technology of brush plating and parts, applied to the field of inner hole brush plating devices, can solve the problems of inability to replenish metal ions, unsatisfactory repair technology, etc., and achieve the cost reduction of brush plating, excellent flexibility, and reduced consumption. Effect

Inactive Publication Date: 2010-11-10

ACADEMY OF ARMORED FORCES ENG PLA

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the repair technology currently used is not ideal. The main defect is that the anode of the plating pen generally uses graphite during brush plating, which cannot replenish metal ions to the plating solution. As the brush plating process progresses, the concentration of metal ions in the plating solution Gradually decrease, the deposition rate and the quality of the coating also gradually decrease. When the metal ion concentration is lower than 40% of the original solution concentration, the plating solution has to be scrapped, and the scrapped plating solution needs strict discharge treatment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

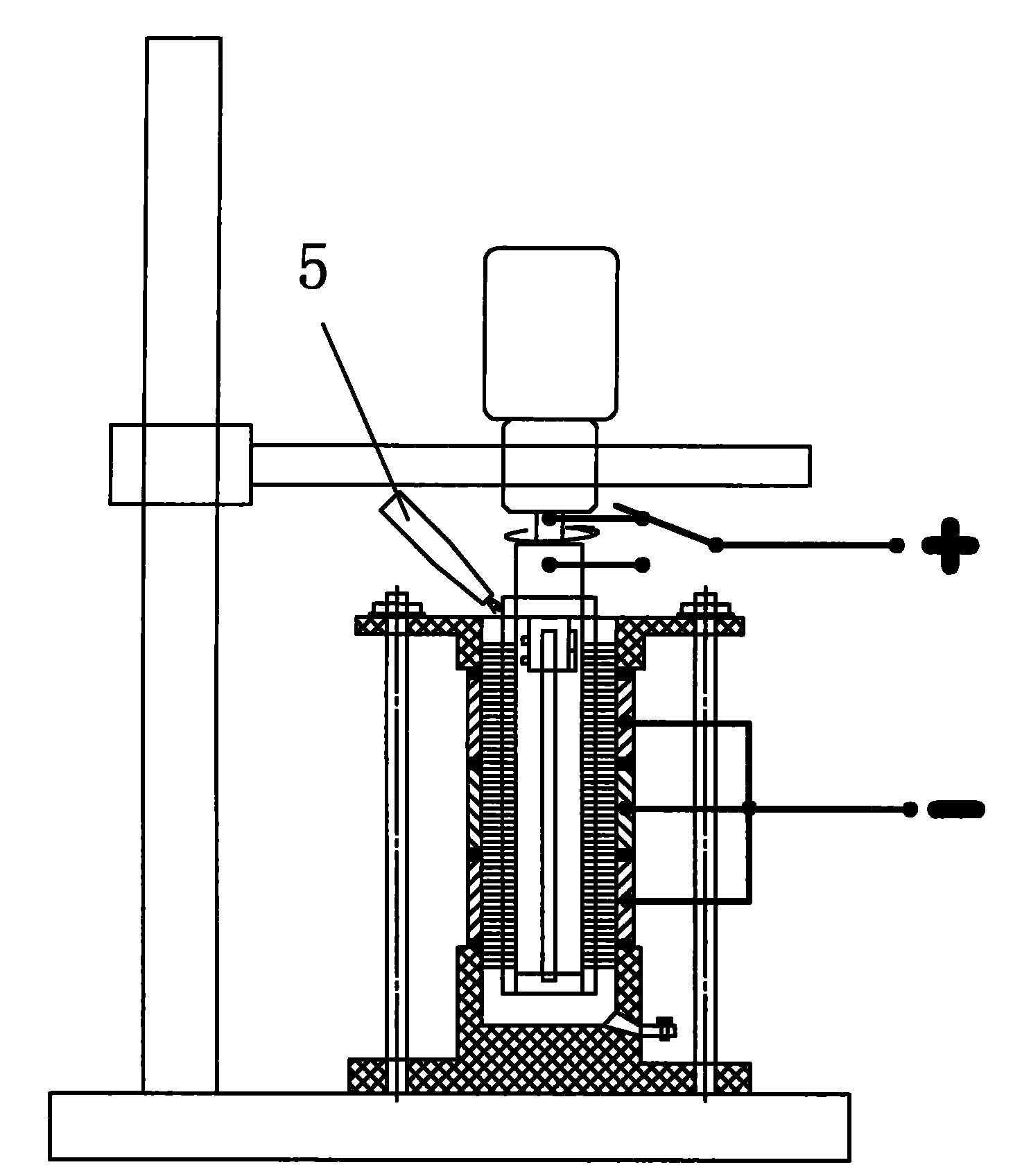

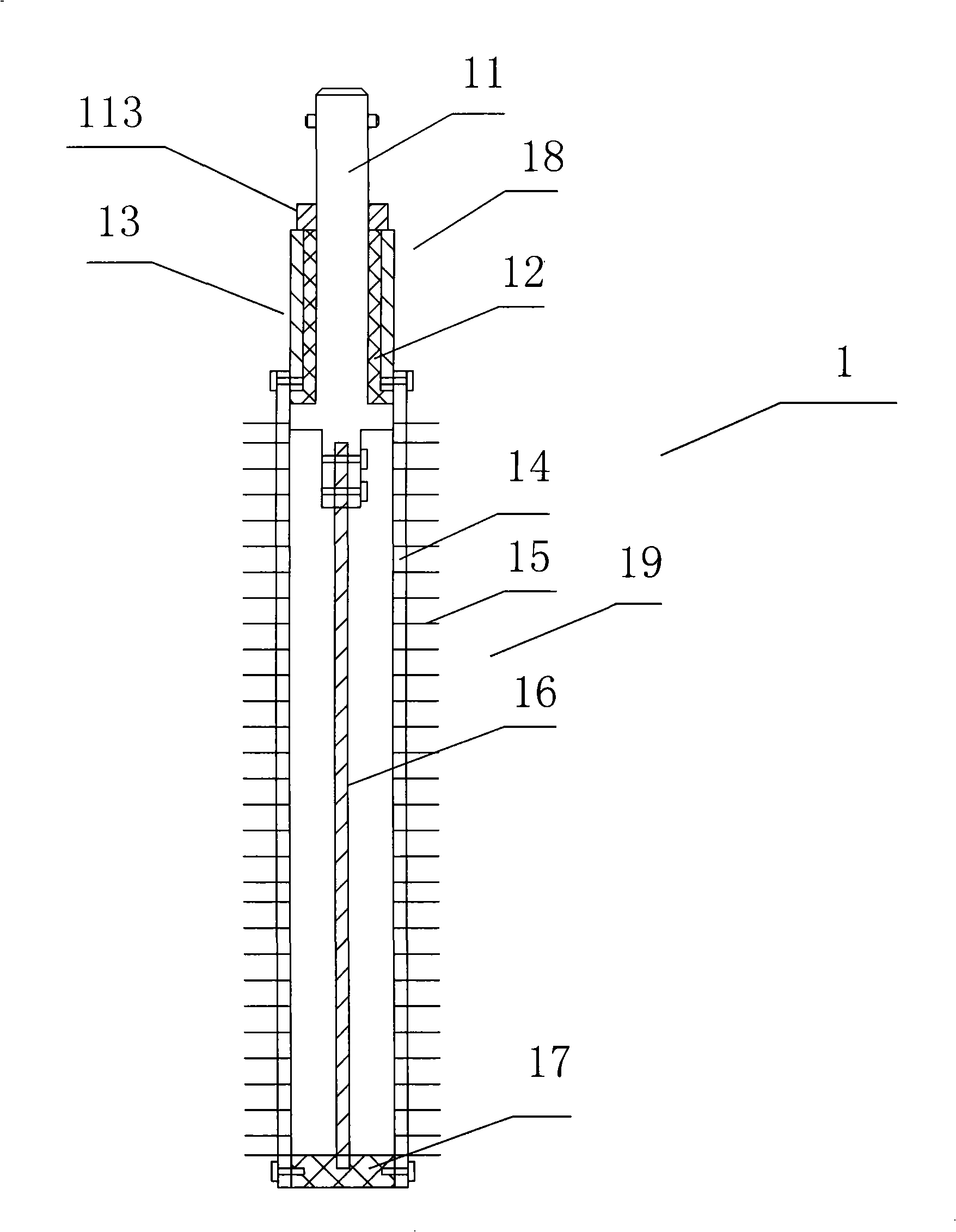

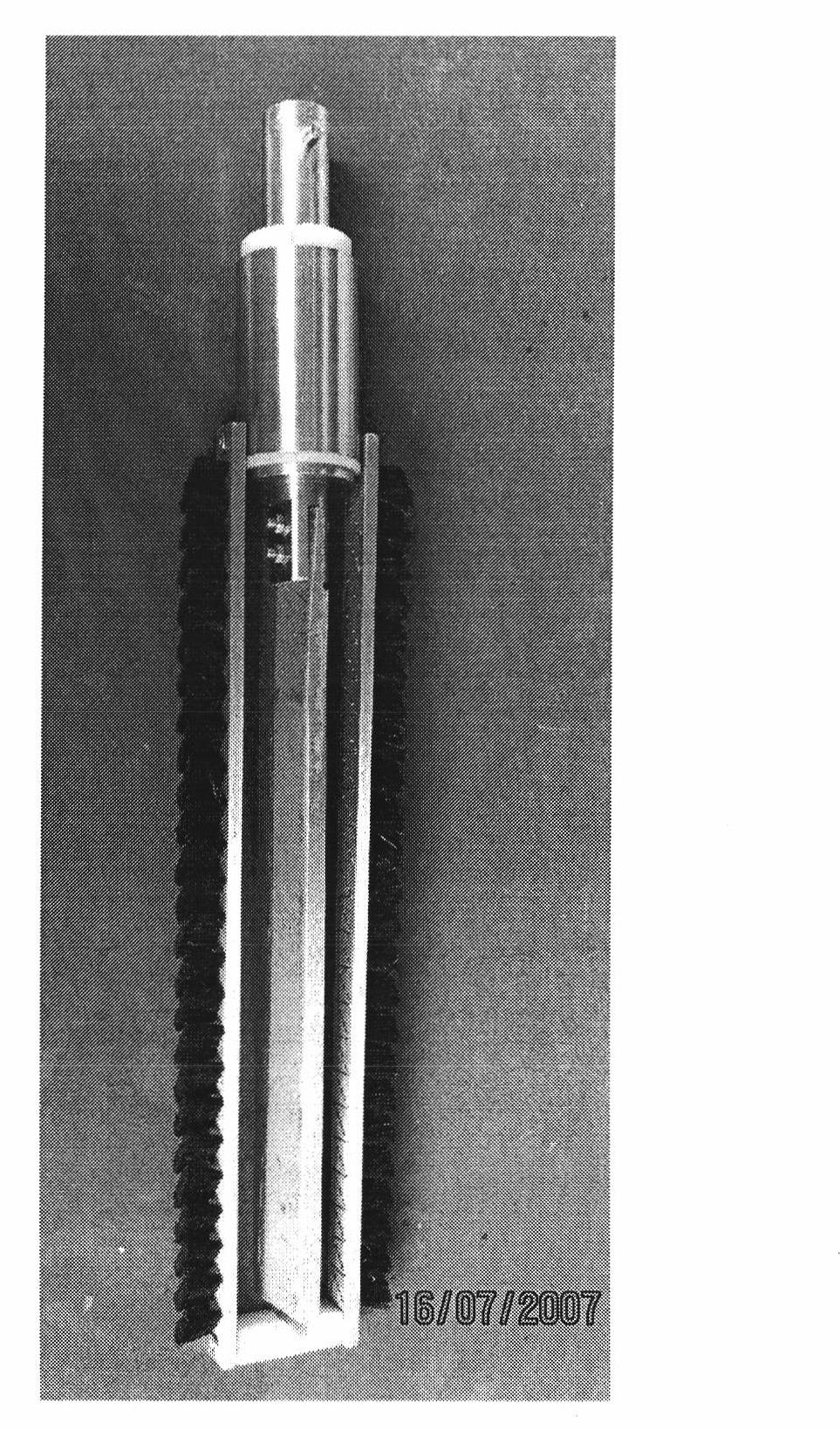

The invention provides a device and method for inner bore type component brush plating. The device comprises a workpiece to be plated, a workpiece clamping sealing device, a plating pen special for inner bore brush plating, and a plating pen rotary actuator. The workpiece to be plated and the clamping sealing device together form a container having an opening at the top; in plating process, the workpiece is the cathode, and the plating pen is the anode. The device and method realize that plating is prepared at the surface of the inner bore of the inner bore type component by using the technology of brush plating, thereby being applied to strengthening for new workpiece and also being applied to batch repair and remanufacturing for damaged pieces.

Description

Device and method for electro-brush plating of inner hole parts technical field The invention relates to an electric brush plating technology, in particular to a device and method for inner hole electric brush plating. This method is aimed at parts with inner holes, and it is not only suitable for strengthening new parts, but also for repairing and remanufacturing of worn parts. Background technique Brush plating is a surface processing technology that uses electrochemical methods to reduce metal ions to metal and deposit them on the surface of metal or non-metal products to form a smooth and dense metal coating that meets the requirements. With the development of science and technology and production, brush plating technology involves more and more fields, and people's requirements for coating are getting higher and higher. At present, the application of metal coating has spread all over the various production and research departments of economic activities, and has grea...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C25D5/06

Inventor 徐滨士胡振峰董世运

Owner ACADEMY OF ARMORED FORCES ENG PLA

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com