Device and method for inner bore type component brush plating

A technology of brush plating and component parts, which is applied in the field of brush plating devices for inner holes, can solve the problems of unsatisfactory repair technology and inability to replenish metal ions, etc., and achieve reduced brush plating costs, strong wear resistance, and reduced clamping The effect of precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 Brush plating device for parts with inner holes (1)

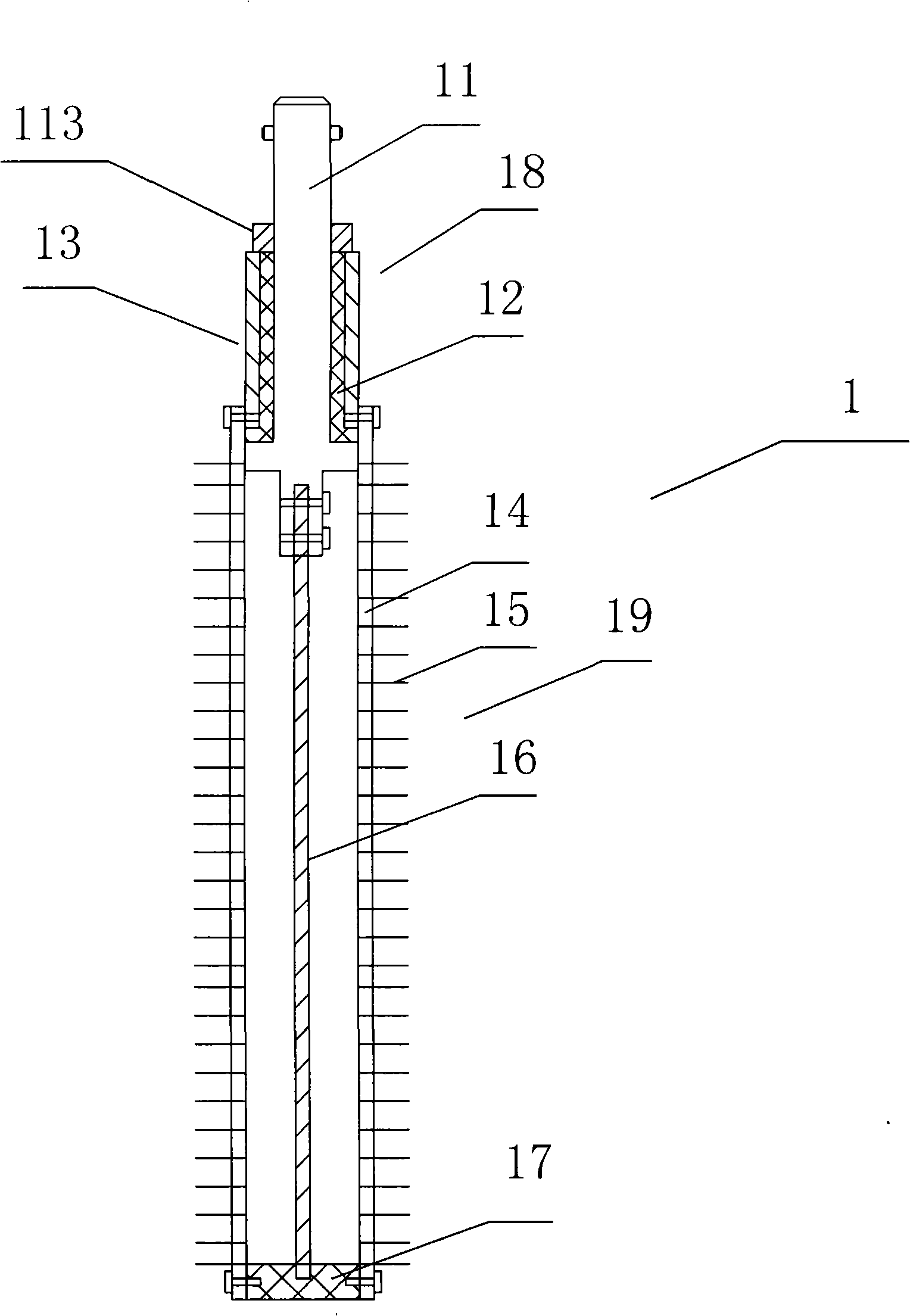

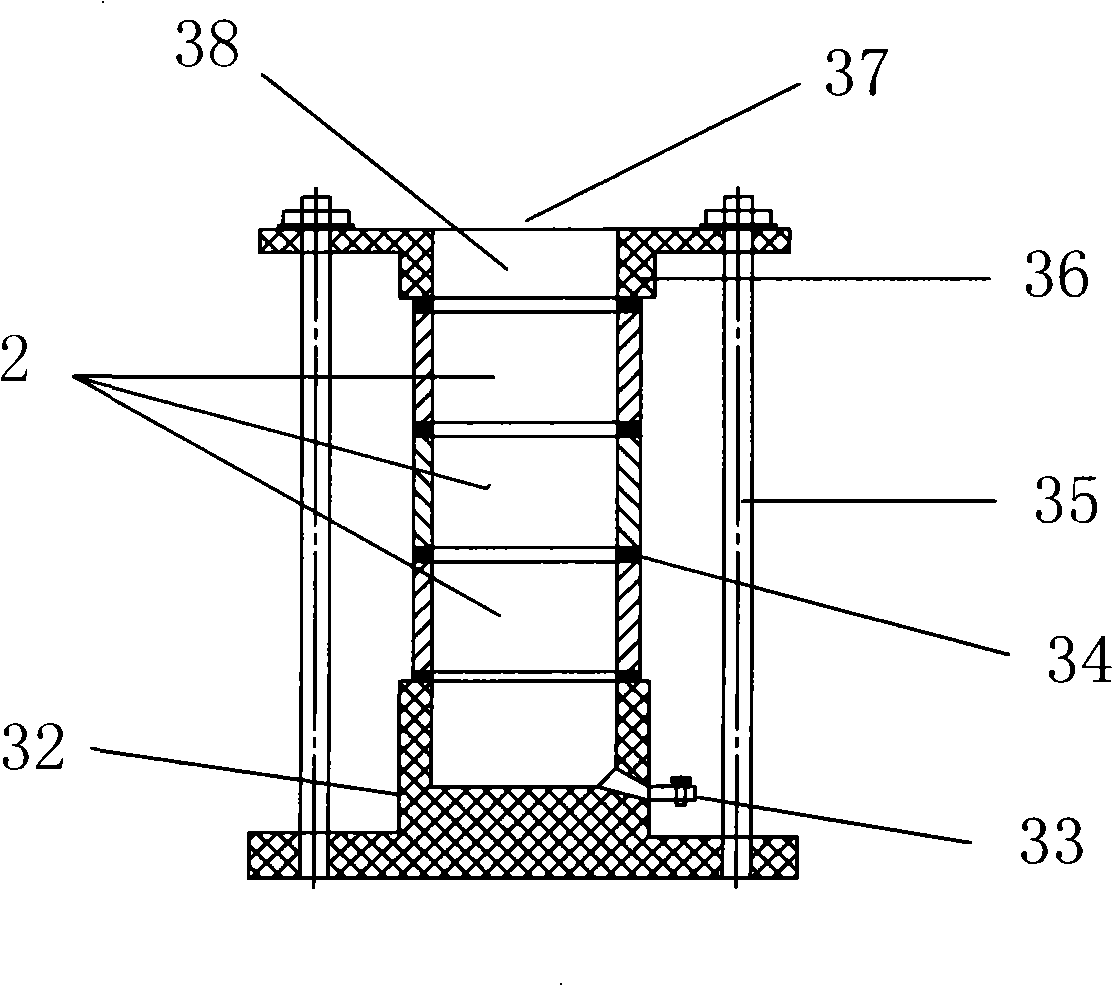

[0046] refer to Figure 1~6 The brush plating device for inner hole parts includes a special plating pen for inner hole brush plating 1, three workpieces to be plated 2, workpiece clamping and sealing device 3, plating pen rotating device 4, liquid injection device 5, power supply and numerical control system ;

[0047] refer to figure 1 and figure 2 , the inner hole brush plating special plating pen 1 includes a handle 18 and a pen body 19; A sleeve 13 is provided, and an anode 16 is connected to the lower end of the mandrel 11; the pen body 19 is composed of two conductive plate bodies 14 and bristles 15, and the bristles 15 are arranged on the outer surface of the conductive plate body 14; the conductive plate body 14 and the sleeve The cylinder 13 is connected, and two conductive plates 14 are arranged in parallel on both sides of the anode 16, and the bottom ends of the two conductive plates 14...

Embodiment 2

[0053] Embodiment 2 Brush plating device for inner hole parts (two)

[0054] refer to Figure 3-7 The brush plating device for inner hole parts includes a special plating pen for inner hole brush plating 1, three workpieces to be plated 2, workpiece clamping and sealing device 3, plating pen rotating device 4, liquid injection device 5, power supply and numerical control system ;

[0055] refer to Figure 7 The special plating pen 1 for inner hole brush plating includes a handle 18, a pen body 19 and an insulating crossbeam 17; , the clamping part is connected to the lower part of the main body of the handle, and the lower end of the clamping part clamps an anode 16; Plates 14 are arranged on both sides of the anode 16 in parallel, and the upper ends of the two plates 14 are connected to the handle main body 110; the lower ends of the two plates 14 and the bottom end of the anode 16 are both arranged on the insulating beam 17 and do not touch each other.

[0056] The dista...

Embodiment 3

[0063] Example 3 Remanufacture of Steyr Engine Connecting Rod Using Inner Hole Brush Plating Technology (1)

[0064] The Steyr engine connecting rod is made of 35CrMo, and its large head hole is fitted with a copper bush after being fitted with the crankshaft. Due to the deformation caused by the impact load for a long time, it cannot meet the matching accuracy requirements, and the size needs to be restored after honing. The standard size of the big head hole is Φ88 0 +0.03 mm, the size after honing is Φ88 +0.08 +0.10 mm.

[0065] refer to Figure 1~6 , using the brushing device of Example 1, wherein the workpiece clamping and sealing device 3 clamps 6 connecting rods at a time, and the connecting rods are remanufactured by using the inner hole electroplating method. The process flow is:

[0066] a. Insert the special plating pen 1 for inner hole brush plating into the container 37. The plating pen 1 is slightly lower than the workpiece by 3cm, and the anode of the plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com