Process for continuously removing quinoline insolubles in coal tar pitch

A technology of coal tar pitch and quinoline, which is applied in the new process field of removing quinoline insolubles from coal tar pitch, can solve the problems of small processing capacity, low solvent recovery rate, high QI content, etc., and achieve the reduction of clear liquid loss, The effect of high solvent recovery and low QI content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

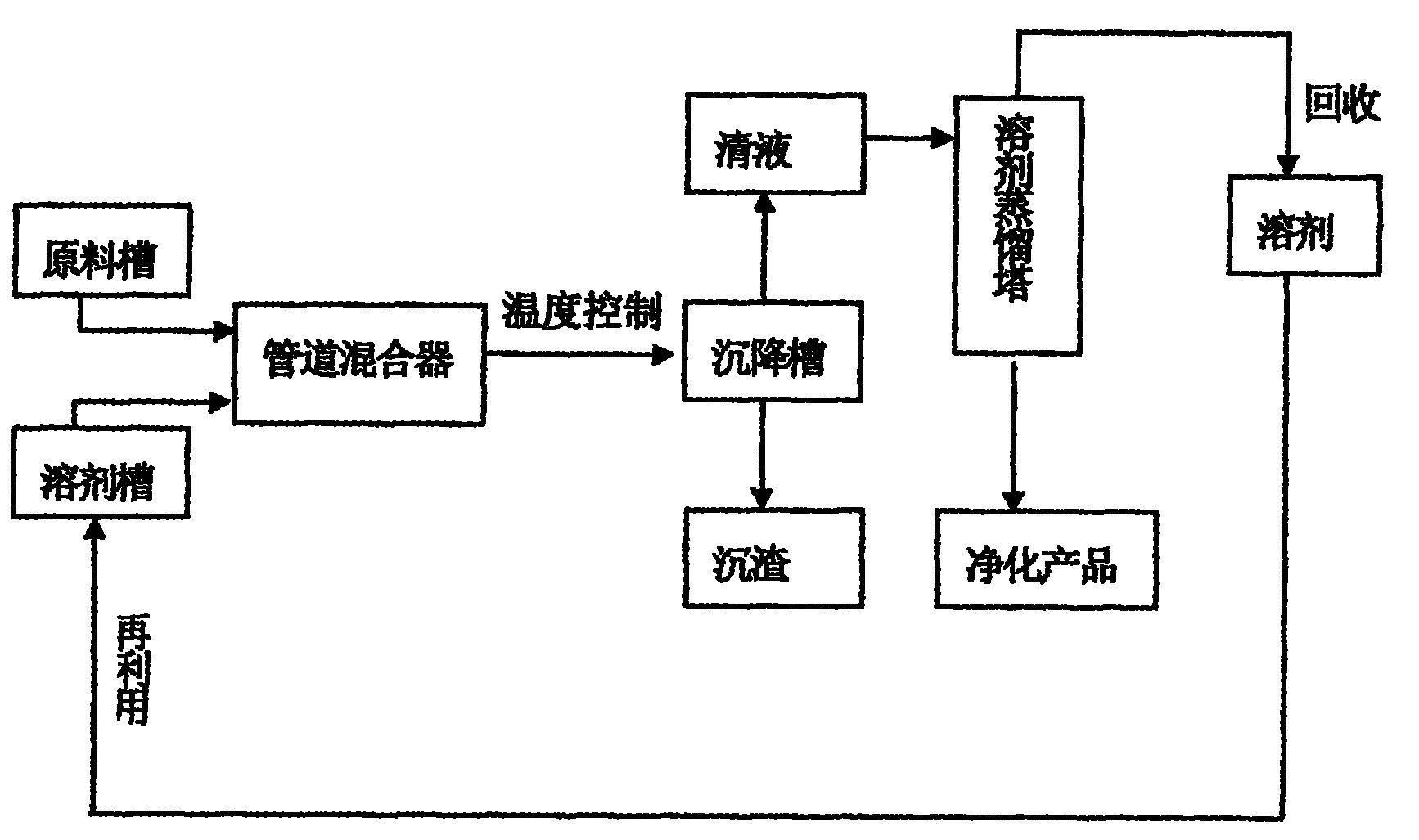

Method used

Image

Examples

Embodiment 1

[0019] The raw material is mixed soft asphalt.

[0020] The flow ratio of soft asphalt to solvent is 1:0.6. The solvent is a mixture of kerosene and aromatic hydrocarbons, and the ratio of kerosene to aromatic hydrocarbons is 0.7:1.

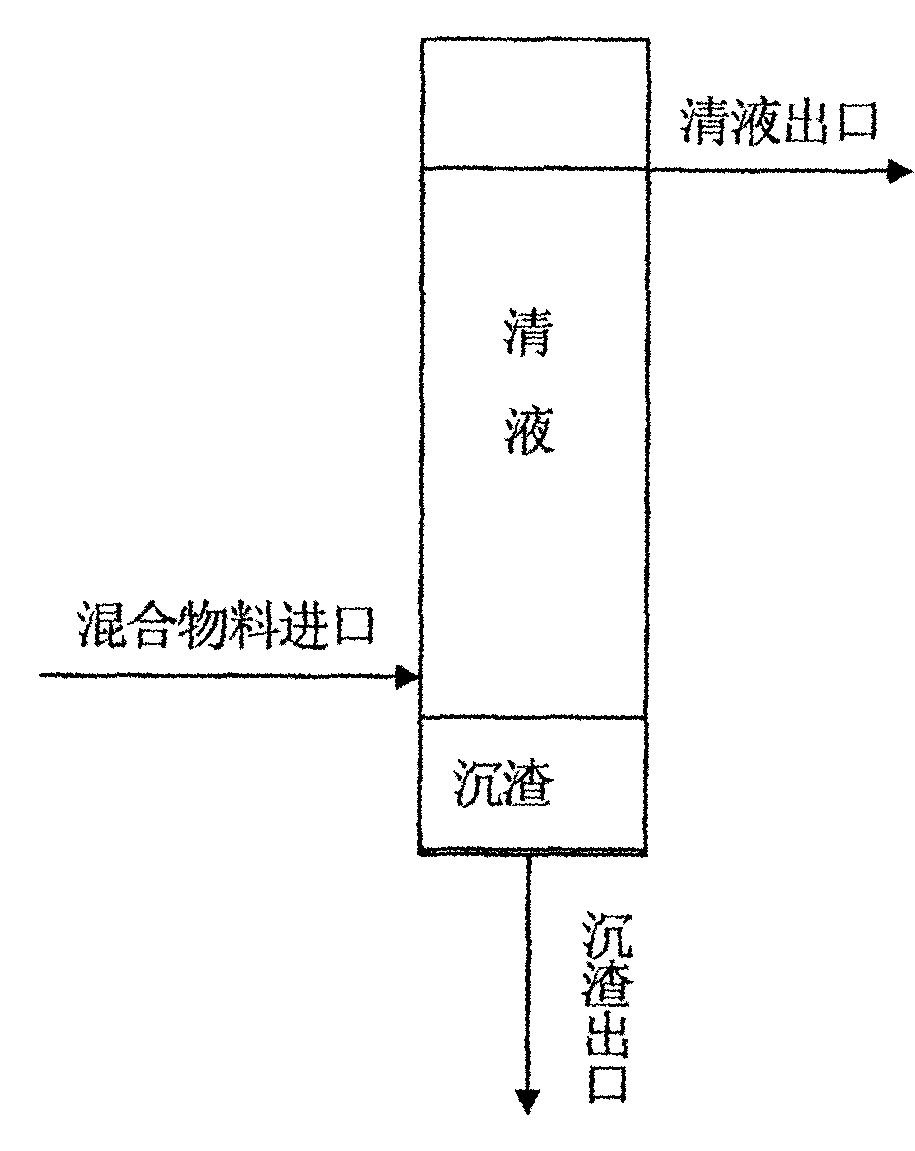

[0021] After fully mixing the returned soft asphalt and the solvent through the pipeline mixer, they continuously enter the lower part of the settling tank. The temperature of the settling tank was 130°C, and the residence time of the mixed material in the settling tank was 24 hours.

[0022] In the settling tank, the mixed material is divided into two phases of clear liquid and sediment. The clear liquid is continuously discharged from the upper part of the settling tank, and the sediment is sent out from the bottom of the settling tank. The clear liquid is processed by a solvent distillation tower to obtain a purified product, and the solvent is recovered. The solvent is recovered for recycling.

[0023] After testing, the product yield (p...

Embodiment 2

[0025] The raw material is mixed soft asphalt.

[0026] The flow ratio of soft asphalt to solvent is 1:2.

[0027] Wherein the solvent is a mixture of hexane and aromatic hydrocarbon, and the ratio of hexane to aromatic hydrocarbon is 0.7:1.

[0028] After fully mixing the returned soft asphalt and the solvent through the pipeline mixer, they continuously enter the lower part of the settling tank. The temperature of the settling tank is 60°C, and the residence time of the mixed material in the settling tank is 12 hours. Others are the same as embodiment 1.

[0029] After testing, the product yield (purified back-mixed soft asphalt / back-mixed soft asphalt) is 87.0%, the solvent recovery rate is 98.5%, and the content of quinoline insolubles (QI) in the purified back-mixed soft asphalt is 0.02%.

Embodiment 3

[0031] The raw material is mixed soft asphalt.

[0032] The flow ratio of soft asphalt to solvent is 1:2. Wherein the solvent is a mixture of heptane and aromatic hydrocarbon, and the ratio of heptane to aromatic hydrocarbon is 1:0.5.

[0033] After fully mixing the returned soft asphalt and the solvent through the pipeline mixer, they continuously enter the lower part of the settling tank. The temperature of the settling tank was 90°C, and the residence time of the mixed material in the settling tank was 3 hours. Others are the same as embodiment 1.

[0034] After testing, the product yield (purified back-mixed soft asphalt / back-mixed soft asphalt) is 89.0%, the solvent recovery rate is 97.0%, and the content of quinoline insolubles (QI) in the purified back-mixed soft asphalt is 0.06%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com