Method for preparing phosphor system halogen-free flame-proof copolymerization polyester

A copolyester and phosphorus-based technology, which is applied in the field of polymer compound preparation, can solve the problem of difficulty in obtaining high flame-retardant grade co-polymerized flame-retardant polyester, limiting the increase of the real content of flame retardants, and failing to achieve halogen-free flame retardants. Combustible products and other issues, to achieve the effect of increasing the effective addition amount, improving the reaction performance, and increasing the flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

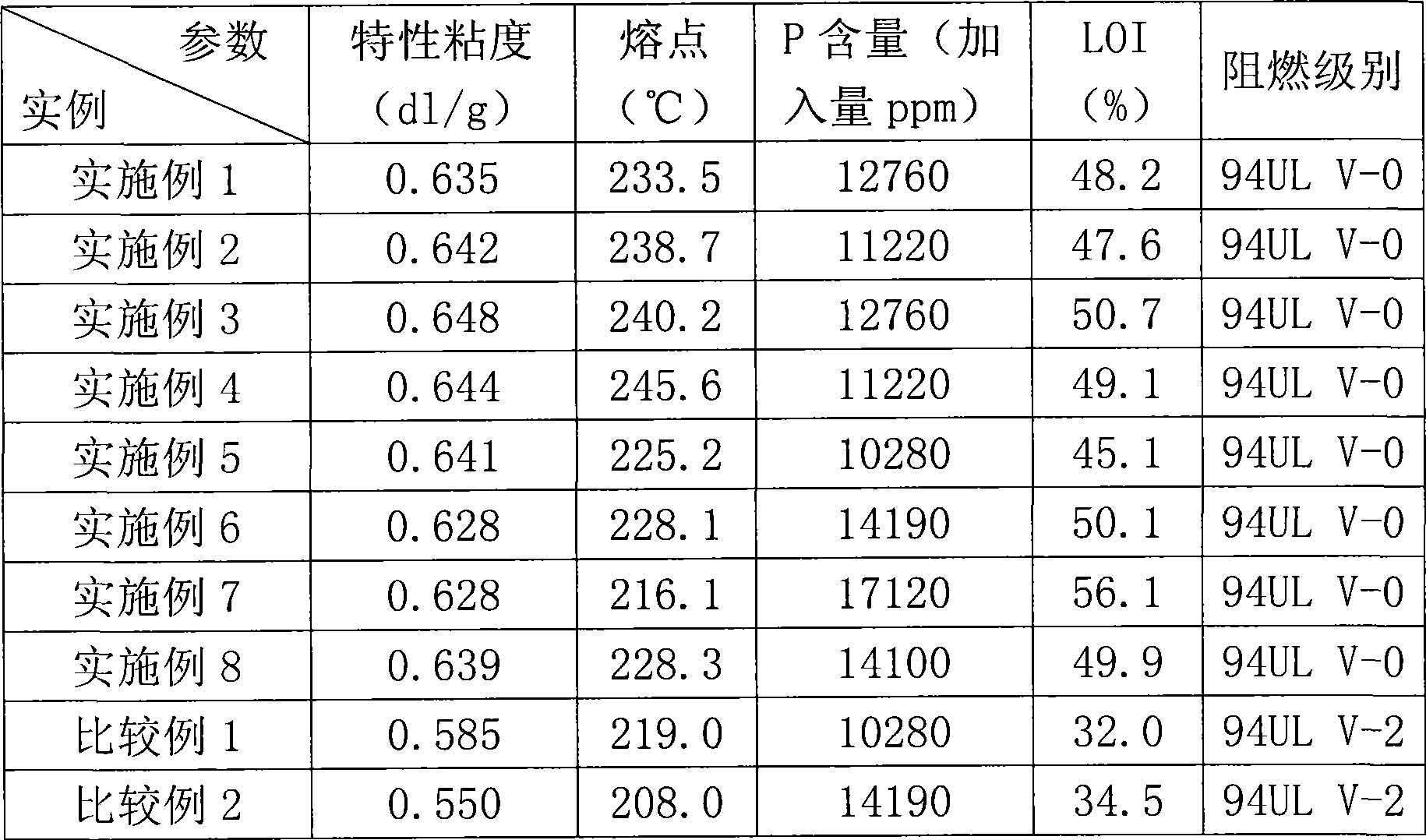

Embodiment 1

[0029] A preparation method of phosphorus-based halogen-free flame-retardant copolyester, comprising the following steps:

[0030] Take 2.1kg of hydroxymethylphenyl hypophosphorous acid and 3.2kg of ethylene glycol, put them into the esterification kettle, raise the temperature to 155°C and fully stir, carry out the esterification reaction under 60kpa pressure for 5 hours, and the esterification reaction reaches more than 95%. The material is filtered, and the filtrate is the esterification liquid for subsequent use;

[0031] Take 25kg of terephthalic acid (PTA), 13kg of ethylene glycol (EG), and 29g of pentaerythritol, stir and mix well, heat to 250°C to 255°C for esterification for 3 hours, and when the esterification reaches 90% or more, Add the aforementioned standby hydroxymethylphenylphosphinic acid pre-esterification solution, then add 20g of catalyst antimony acetate and 20g of stabilizer phosphoric acid and stir evenly, gradually depressurize to below 100pa and carry ...

Embodiment 2

[0033] A preparation method of phosphorus-based halogen-free flame-retardant copolyester, comprising the following steps:

[0034] The preparation method of this embodiment is different from Example 1 in that: when preparing the flame retardant pre-esterification liquid, the addition amount of hydroxymethylphenyl hypophosphorous acid is 1.8kg, and the addition amount of ethylene glycol is 2.75kg. The amount of phosphorus (P) added to the flame-retardant polyester chips was 11220ppm. Others are identical with embodiment 1, omitted.

Embodiment 3

[0036] A preparation method of phosphorus-based halogen-free flame-retardant copolyester, comprising the following steps:

[0037] Take 2.1kg of hydroxymethylphenyl hypophosphorous acid and 3.5kg of ethylene glycol into the esterification kettle, polycondense at 155°C and pressure below 1000Pa for 3 to 4 hours, discharge and filter for later use.

[0038] Take 25kg of terephthalic acid (PTA), 13kg of ethylene glycol (EG), and 29g of pentaerythritol, stir and mix well, heat to 250°C-255°C for esterification reaction for 2-4 hours, and the esterification reaction is over 90%. , add the aforementioned standby hydroxymethylphenylphosphinate prepolymer, add 16g of catalyst antimony trioxide and 25g of stabilizer trimethyl phosphate, stir evenly, gradually reduce the pressure to below 100pa, and carry out polycondensation at a temperature of 285°C Reaction, polymerization reaction for 2.5 to 3 hours, and the phosphorus-based halogen-free flame-retardant copolyester is obtained after d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com