Multilayer piezoelectric device and ejection apparatus

A piezoelectric element and multilayer technology, which is applied in the field of multilayer piezoelectric elements and injection devices, can solve problems such as poor contact, failure to supply voltage, and disconnection of the external electrode 70, so as to achieve good durability, prevent disconnection, The effect of promoting interdiffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

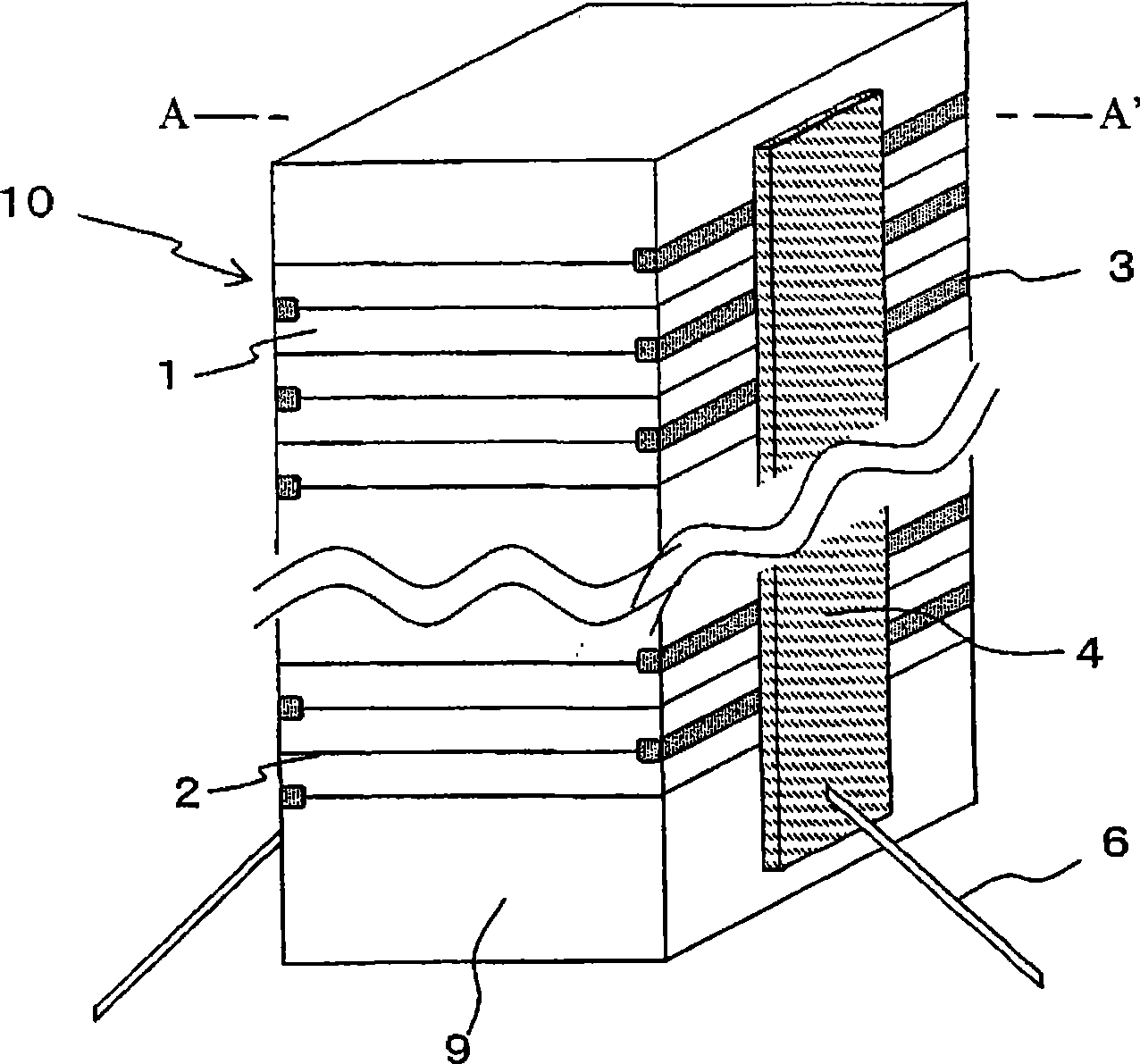

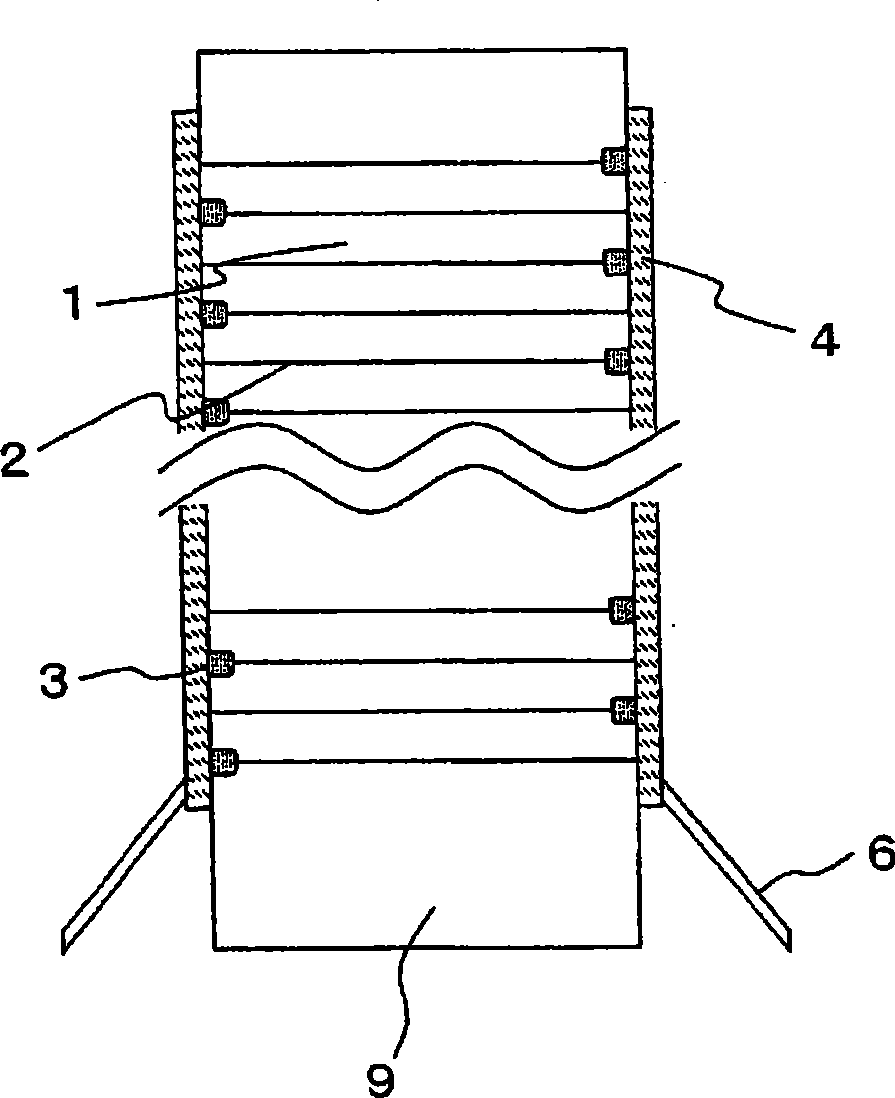

[0086] Figure 1A It is a perspective view of a multilayer piezoelectric element (a multilayer piezoelectric actuator) according to Embodiment 1 of the present invention, Figure 1B is along Figure 1A Longitudinal sectional view of line A-A' in .

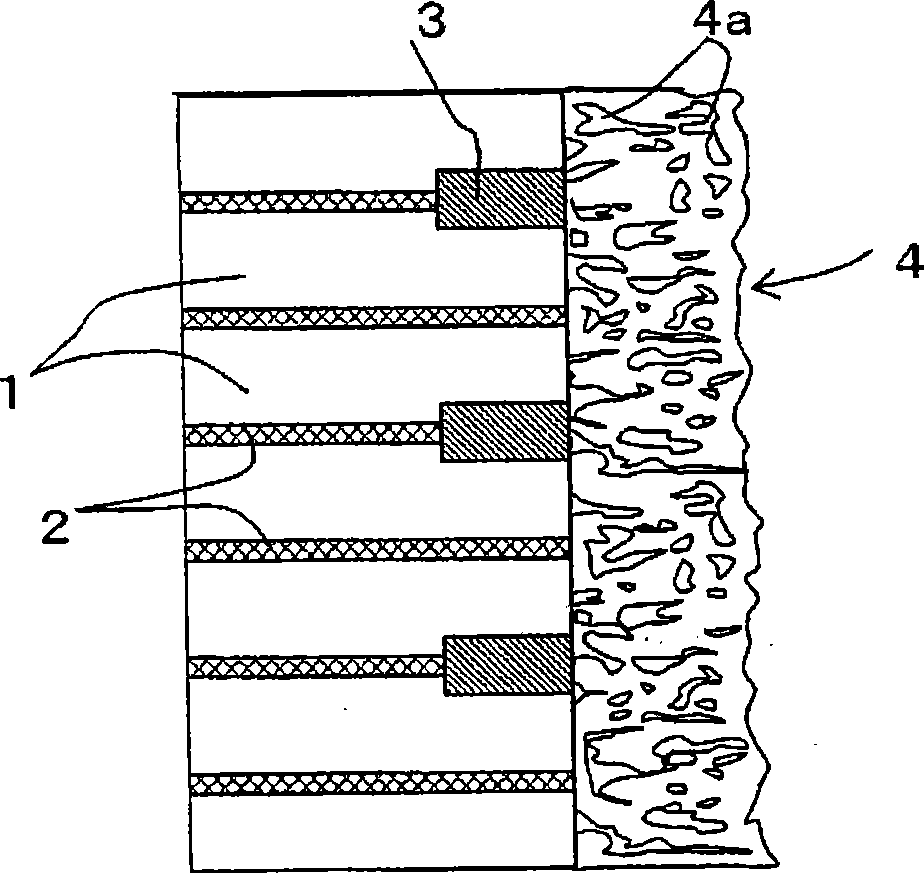

[0087] The multilayer piezoelectric actuator of the first embodiment, such as Figure 1A , 1B As shown in FIG. External electrodes 4 constitute. Specifically, the configuration is as follows: On the side surface on which the external electrodes 4 are formed, the ends of the internal electrodes 2 are covered with an insulator 3 every other layer, and the ends of the internal electrodes 2 not covered by the insulator 3 are connected with the external electrodes. 4 conduction. Also, the external electrodes 4 are made of a porous conductor having a three-dimensional network structure composed of a conductive material mainly composed of silver and glass, and lead wires 6 are connected to the respective external electrodes 4 . In ...

Embodiment approach 2

[0128] In the multilayer piezoelectric element (multilayer piezoelectric actuator) according to the second embodiment of the present invention, in the multilayer piezoelectric element according to the first embodiment, the external electrodes 4 and the internal electrodes 2 are configured as follows.

[0129] In the multilayer piezoelectric actuator according to Embodiment 2, the external electrodes 4 are made of a conductive material mainly composed of silver and glass, and the internal electrodes 2 include the conductive material and the piezoelectric material.

[0130] Also, let the weight ratio of silver in the conductive material of the internal electrode 2 be X (%), the weight ratio of silver in the internal electrode 2 including the conductive material and the piezoelectric material be Z (%), and the silver weight ratio in the external electrode 4 be Z (%). When the weight ratio is Y (%), each ratio is set so that X≧85 and 0.9≦X / Y≦1.1 are satisfied. This is for the foll...

Embodiment approach 3

[0166] The multilayer piezoelectric element (multilayer piezoelectric actuator) according to Embodiment 3 of the present invention is characterized in that Figure 1A , Figure 1B In the element shown in FIG. The silver ratio of the conductive material in the internal electrode 2 near the connection portion with the external electrode 4 is higher than the silver ratio of the conductive material in the internal electrode 2 inside the laminate 10 .

[0167] By making the silver ratio of the conductive material of the internal electrode 2 near the connection portion with the external electrode 4 larger than the silver ratio of the conductive material in the internal electrode 2 inside the laminate 10, the main content of the conductive material of the external electrode 4 can be increased. Since silver, which is a component, is close to the concentration of silver in the conductive material of the internal electrodes 2, the bonding between the external electrodes 4 and the inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com