Preparation of polyphenyl thioether fiber

A technology of polyphenylene sulfide fiber and polyphenylene sulfide, applied in the field of preparation of polyphenylene sulfide fiber, can solve the problems of PPS fiber characteristics decline, difficulty in applying PPS, spinning stability deterioration, etc., and achieve spinning performance Good, less decrease in mechanical strength, less disconnection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

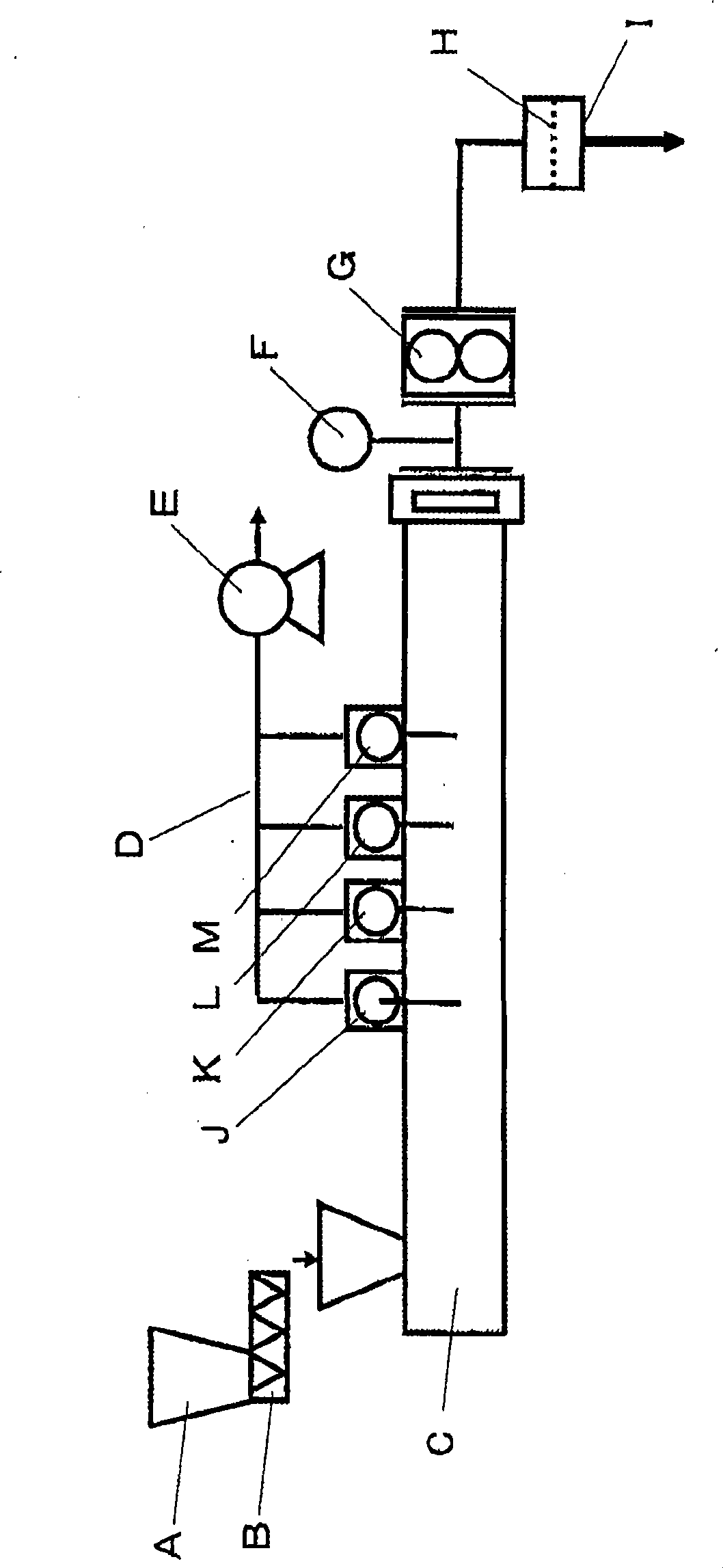

Method used

Image

Examples

Embodiment 1

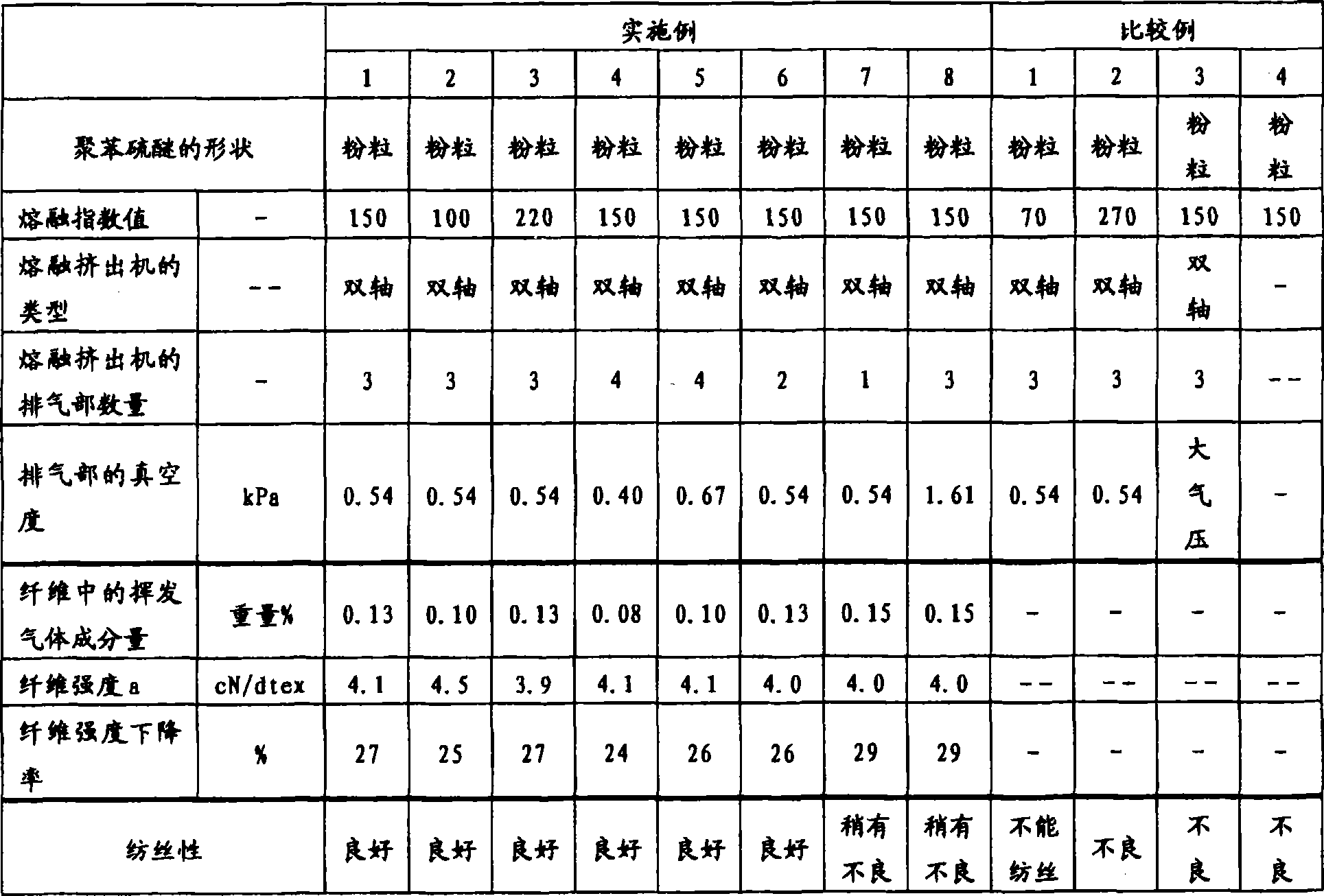

[0089] A predetermined amount of "Torelina" PPS powder E2280 (particle size: 1500 μm) manufactured by Toray Co., Ltd. with a melt index value of 150 was continuously fed into a twin-screw extruder with a vent hole (manufactured by Nippon Steel Co., Ltd. TEX30 type). The number of exhaust parts attached to the barrel of the extruder is 3, so that the vacuum degree of each is the same, and the vacuum degree in the barrel is 0.54kPa, and the temperature in the barrel is 320°C. The screw speed was 160 rpm. The molten material melted and transported in the barrel flows out of the barrel at a predetermined pressure and speed, is filtered through a filter with a mesh size of 150 μm, and is spun from a spinning nozzle. The heating temperature in the spinning nozzle was set at 320° C., the number of orifices in the spinning nozzle used was 700H, the orifice diameter was 0.2 mm, and the hole depth was 1.0 mm, so that the discharge rate was 370 g / min.

[0090] After the fibers obtained...

Embodiment 2

[0093] PPS short fibers were produced in the same manner as in Example 1, except that the PPS powder used was changed to "Torelina" PPS powder E2080 (particle size: 1500 μm) manufactured by Toray Co., Ltd. with a melt index value of 100. For the obtained PPS short fibers, the content of volatile gas components and fiber strength were measured, and the same heat treatment as in Example 1 was carried out, then the fiber strength was measured, and the fiber strength reduction rate was obtained. The results are shown in Table 1. The obtained PPS short fibers had a low content of gas volatile components and had good thermal durability. In addition, no problem was encountered during spinning, and the spinnability was good.

Embodiment 3

[0095] PPS short fibers were prepared in the same manner as in Example 1, except that the PPS powder used was changed to "Torelina" PPS powder M2481 (particle size: 1500 μm) manufactured by Toray Co., Ltd. with a melt index value of 220. For the obtained PPS short fibers, the content of volatile gas components and fiber strength were measured, and the same heat treatment as in Example 1 was carried out, then the fiber strength was measured, and the fiber strength reduction rate was obtained. The results are shown in Table 1. The obtained PPS short fibers had a low content of gas volatile components and had good thermal durability. In addition, no problem was encountered during spinning, and the spinnability was good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com