Rapid liquefaction method for corps wastes by microwave heating catalysis

A microwave heating and waste technology, applied in the field of crop waste utilization, can solve the problems of low efficiency, long liquefaction time, high cost, etc., and achieve the effect of cost reduction and fast operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

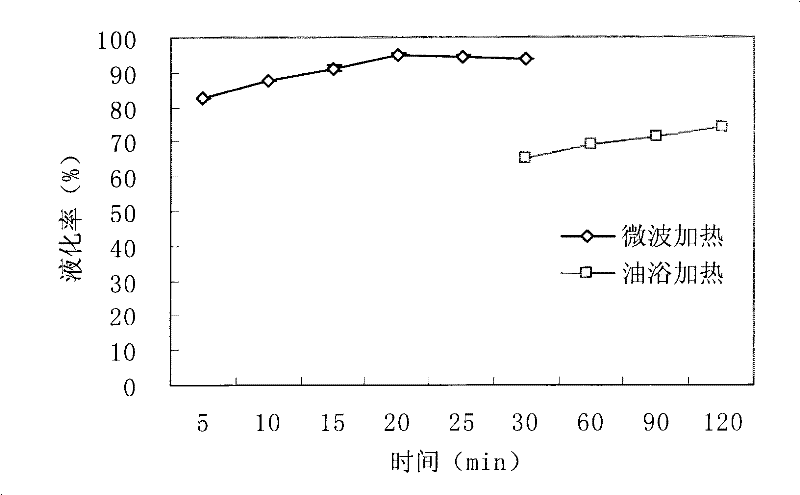

Embodiment 1

[0018] Crush corn stalks to 40 mesh, weigh 6 g of corn stalk powder, add 20 g of liquefier ethylene glycol and 0.7 g of catalyst 98% concentrated sulfuric acid, that is, the mass of straw is 30% of the mass of liquefier, and the concentrated sulfuric acid is 3.5% of the mass of liquefier , set the microwave temperature at 160°C, the microwave power at 600W, adopt a closed microwave heating method, and magnetically stir the liquefaction reaction for 25 minutes to obtain the corn stalk liquefaction product biomass polyol.

[0019] After testing, the liquefaction rate of corn stalks reached 94.6% under the liquefaction conditions.

Embodiment 2

[0021] Crush corn stalks to 40 mesh, add liquefaction agent polyethylene glycol 400 and glycerol 4:1 (v / v) mixture and catalyst 98% concentrated sulfuric acid to corn stalk powder, the quality of liquefaction agent is 25g, and the quality of straw is the quality of liquefaction agent The concentrated sulfuric acid is 3.5% of the mass of the liquefaction agent, the microwave temperature is set at 150°C, the microwave power is 400W, and the closed microwave heating is adopted, and the liquefaction reaction is carried out by magnetic stirring for 20 minutes to obtain the corn stalk liquefaction product biomass polyol.

[0022] After testing, the liquefaction rate of corn stalks reached 92.4% under the liquefaction conditions.

Embodiment 3

[0024] Corncobs are pulverized to 40 mesh, liquefaction agent ethylene glycol and catalyst 98% concentrated sulfuric acid are added to the corncob powder, the quality of the liquefaction agent is 250g, the quality of the corncobs is 20% of the quality of the liquefaction agent, and the concentrated sulfuric acid is 5.0% of the quality of the liquefaction agent , set the microwave temperature at 150°C, the microwave power at 1000W, adopt closed microwave heating, and magnetically stir the liquefaction reaction for 20 minutes to obtain the corncob liquefaction product biomass polyol. Under this liquefaction condition, the liquefaction rate of corn cob reaches 91.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com