A method for direct liquefaction of biomass

A biomass and direct technology, which is applied in the preparation of liquid hydrocarbon mixtures, the treatment of hydrocarbon oil, and the petroleum industry. The effect of reducing and reducing industrial costs and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

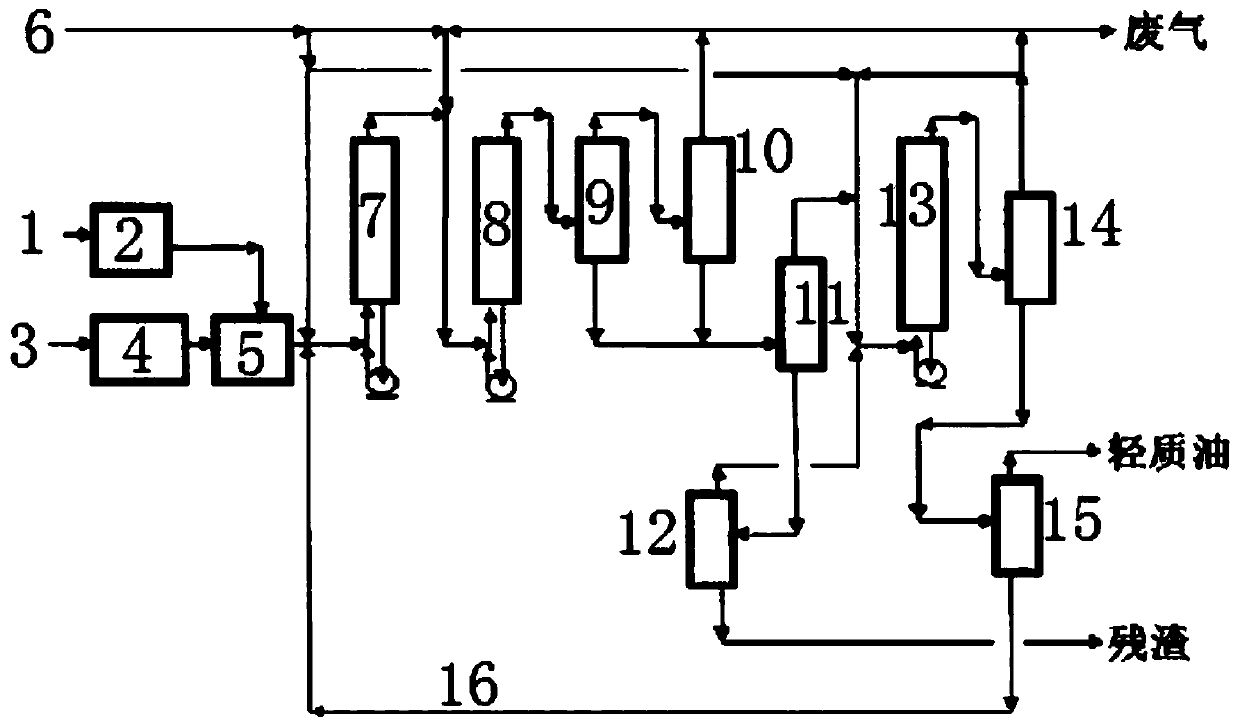

[0055] 本发明实施例所提供的生物质直接液化的方法,包括如下步骤:

[0056] (1)将棕榈油渣1进入生物质前处理装置2中依次进行干燥、初粉碎、压缩、二次粉碎,其中,干燥温度为80℃、时间为5h,经干燥后棕榈油渣的含水量低于2wt%,初粉碎后的中位粒径为100μm,压缩温度为50℃、压力为3MPa,经二次粉碎后得到中位粒径为30μm的棕榈油渣颗粒,棕榈油渣颗粒的堆密度为1500kg / m 3 ;

[0057] (2)无定型氧化铝3进入加氢催化剂制备装置4中进行负载,得到无定型氧化铝上负载有Mo氧化物和Ni氧化物的加氢催化剂(其粒度为20μm,负载量为10wt%),将棕榈油渣颗粒、上述加氢催化剂和硫磺按质量比为100:3:0.4在生物质浆液制备装置5中混合,得到混合物;

[0058] (3)将混合物加入至供氢溶剂中搅拌制浆,制得固含量为60wt%的生物质浆液,其中供氢溶剂为中低温煤焦油,该浆液的粘度为700mPa﹒s(50℃);

[0059] (4)将上述生物质浆液和氢气6进入第一强制循环悬浮床反应器7中进行第一液化反应,收集第一反应产物,其中,第一液化反应的条件如下:反应温度为300℃、反应压力为15MPa、气液比为1300NL / kg;所述生物质浆液的空速为1.5t / m 3 ·h;

[0060] (5)第一反应产物和氢气进入第二强制循环悬浮床反应器8中进行第二液化反应,收集第二反应产物,其中,第二液化反应的反应条件如下:反应温度为460℃、反应压力为22MPa、气液比为850NL / kg、所述生物质浆液的空速为1.3t / m 3 ·h;

[0061] (6)所述第二反应产物进入高温分离器9中,并于320℃下进行第一气液分离,收集第一液相和第一气相;

[0062] (7)所述第一气相进入低温分离器10中,并于45℃下进行第二气液分离,收集第二液相,混合所述第一液相和所述第二液相得到液相;

[0063] (8)所述液相进入蒸馏塔11中于320℃、0.5Mpa下进行第一蒸馏,收集轻质馏分和重质馏分;

[0064] (9)所述重质馏分进入减压蒸馏塔12中于350℃、15kpa下进行第二蒸馏,分离出馏出油和残渣,所述轻质馏分和所述馏出油为液化后所得液体。

[0065] 经测试,生物质的液体油收率为70...

Embodiment 2

[0068] 本发明实施例所提供的生物质直接液化的方法,包括如下步骤:

[0069] (1)将亚麻油渣和花生油渣1进入生物质前处理装置2中依次进行干燥、初粉碎、压缩、二次粉碎,其中,干燥温度为110℃、时间为4h,经干燥后亚麻油渣和花生油渣的总含水量低于2wt%,初粉碎后的中位粒径为300μm,压缩温度为55℃、压力为5MPa,经二次粉碎后得到中位粒径为50μm的亚麻油渣和花生油渣的混合颗粒,上述混合颗粒的堆密度为1600kg / m 3 ;

[0070] (2)无定型氧化铝3进入加氢催化剂制备装置4中进行负载,得到无定型氧化铝上负载有Mn氧化物和Fe氧化物的加氢催化剂(其粒度为10μm,负载量为25wt%),将上述混合颗粒、加氢催化剂和二硫化碳按质量比为100:1:0.2在生物质浆液制备装置5中混合,得到混合物;

[0071] (3)将混合物加入至供氢溶剂中分散制浆,制得固含量为65wt%的生物质浆液,其中供氢溶剂为柴油和废塑料油的混合油,该浆液的粘度为300mPa﹒s(50℃);

[0072] (4)将上述生物质浆液和氢气6进入第一强制循环悬浮床反应器7中进行第一液化反应,收集第一反应产物,其中,第一液化反应的条件如下:反应温度为460℃、反应压力为13MPa、气液比为1200NL / kg;所述生物质浆液的空速为1.0t / m 3 ·h;

[0073] (5)第一反应产物和氢气进入第二强制循环悬浮床反应器8中进行第二液化反应,收集第二反应产物,其中,第二液化反应的反应条件如下:反应温度为300℃、反应压力为25MPa、气液比为1500NL / kg、所述生物质浆液的空速为1.5t / m 3 ·h;

[0074] (6)所述第二反应产物进入高温分离器9中,并于290℃下进行第一气液分离,收集第一液相和第一气相;

[0075] (7)所述第一气相进入低温分离器10中,并于60℃下进行第二气液分离,收集第二液相,混合所述第一液相和所述第二液相得到液相;

[0076] (8)所述液相进入蒸馏塔11中于400℃、0.1Mpa下进行第一蒸馏,收集轻质馏分和重质馏分;

[0077] (9)所述重质馏分进入减压蒸馏塔12中于300℃、20kpa下进行第二蒸馏,分离出馏出油和残渣,所述轻质馏分和所述馏出油为液化后所得液体。 ...

Embodiment 3

[0081]The method for direct liquefaction of biomass provided by the embodiments of the present invention comprises the following steps:

[0082] (1) Put the saponin oil residue and rapeseed oil residue 1 into the biomass pretreatment device 2 for drying, primary crushing, compression and secondary crushing in sequence, wherein the drying temperature is 90°C and the time is 2h. After drying The total of saponin oil residue and rapeseed oil residue is less than 2wt%, the median particle size after primary crushing is 200μm, the compression temperature is 40°C, and the pressure is 4MPa, and the soap with a median particle size of 40μm is obtained after secondary crushing Mixed particles of horn oil residue and rapeseed oil residue, the bulk density of the mixed particles is 1560kg / m 3 ;

[0083] (2) The amorphous alumina 3 enters the hydrogenation catalyst preparation device 4 for loading, and obtains a hydrogenation catalyst (which has a particle size of 15 μm and a loading cap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com