Direct liquefaction method of biomass

A biomass and direct technology, which is applied in the preparation of liquid hydrocarbon mixtures, the treatment of hydrocarbon oil, and the petroleum industry. It can solve the problems of high residual solid content in liquid oil, low amount of biomass transported by pumps, and unstable transportation. Achieve the effects of reducing porosity, realizing smooth operation and transportation, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

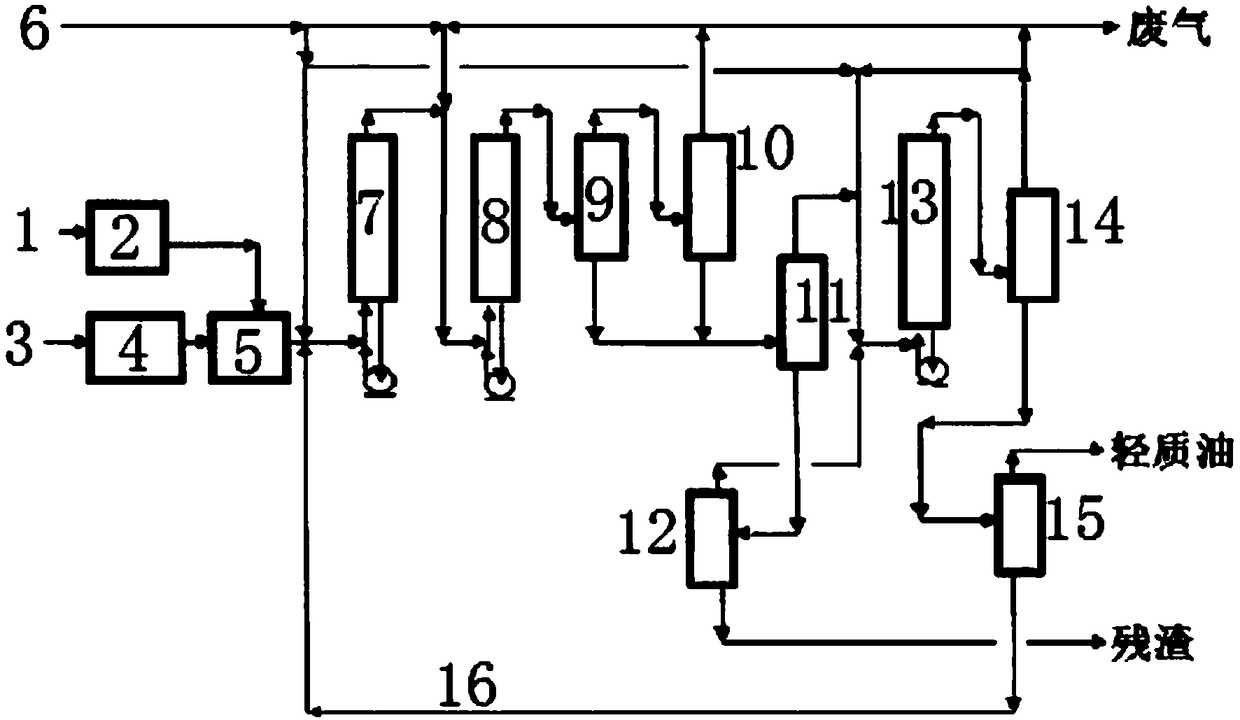

[0056] The method for direct liquefaction of biomass provided by the embodiments of the present invention comprises the following steps:

[0057] (1) Put the wheat straw 1 into the biomass pretreatment device 2 for drying, primary crushing, compression, and secondary crushing in sequence, wherein the drying temperature is 50°C and the drying time is 5 hours, and the moisture content of the dried straw is lower than 2wt %, the median particle size after primary crushing is 100μm, the compression temperature is 30°C, and the pressure is 3MPa. After secondary crushing, wheat straw particles with a median particle size of 30μm are obtained, and the bulk density of wheat straw particles is 500kg / m 3 ;

[0058] (2) The amorphous alumina 3 enters the hydrogenation catalyst preparation device 4 for loading to obtain a hydrogenation catalyst with Mo oxide and Ni oxide loaded on the amorphous alumina (its particle size is 20 μm, and the loading capacity is 10wt%) , mixing the wheat str...

Embodiment 2

[0069] The method for direct liquefaction of biomass provided by the embodiments of the present invention comprises the following steps:

[0070] (1) Put soybean straw, ramie straw, and sorghum straw 1 into the biomass pretreatment device 2 for drying, primary crushing, compression, and secondary crushing in sequence. The drying temperature is 70°C and the drying time is 3 hours. The water content is lower than 2wt%, the median particle size after primary crushing is 300μm, the compression temperature is 60°C, and the pressure is 0.5MPa. After secondary crushing, soybean straw, ramie straw and sorghum straw with a median particle size of 50μm are obtained. Mixed granules of straw, the bulk density of the above mixed granules is 400kg / m 3 ;

[0071] (2) The amorphous alumina 3 enters the hydrogenation catalyst preparation device 4 for loading to obtain a hydrogenation catalyst with Mn oxides and Fe oxides loaded on the amorphous alumina (its particle size is 10 μm, and the loa...

Embodiment 3

[0082] The method for direct liquefaction of biomass provided by the embodiments of the present invention comprises the following steps:

[0083] (1) Put corn stalks and broad bean stalks 1 into the biomass pretreatment device 2 for drying, primary crushing, compression, and secondary crushing in sequence. The drying temperature is 60°C and the drying time is 4 hours. The water content is less than 2wt%, the median particle size after primary crushing is 200μm, the compression temperature is 40°C, and the pressure is 2MPa, and the mixed particles of corn straw and broad bean straw with a median particle size of 40μm are obtained after secondary crushing. The bulk density of the mixed particles is 440kg / m 3 ;

[0084] (2) The amorphous alumina 3 enters the hydrogenation catalyst preparation device 4 for loading, and obtains a hydrogenation catalyst (which has a particle size of 15 μm and a loading capacity of 15 wt%) with W oxide and Pd oxide loaded on the amorphous alumina. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com