Picosecond laser machining apparatus for processing nozzle micropore

A micro-hole processing and picosecond laser technology, which is used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of limited aperture-depth ratio, low processing efficiency, and reduced processing accuracy, so as to improve processing accuracy and High quality, machining efficiency and precision, and the effect of improving machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

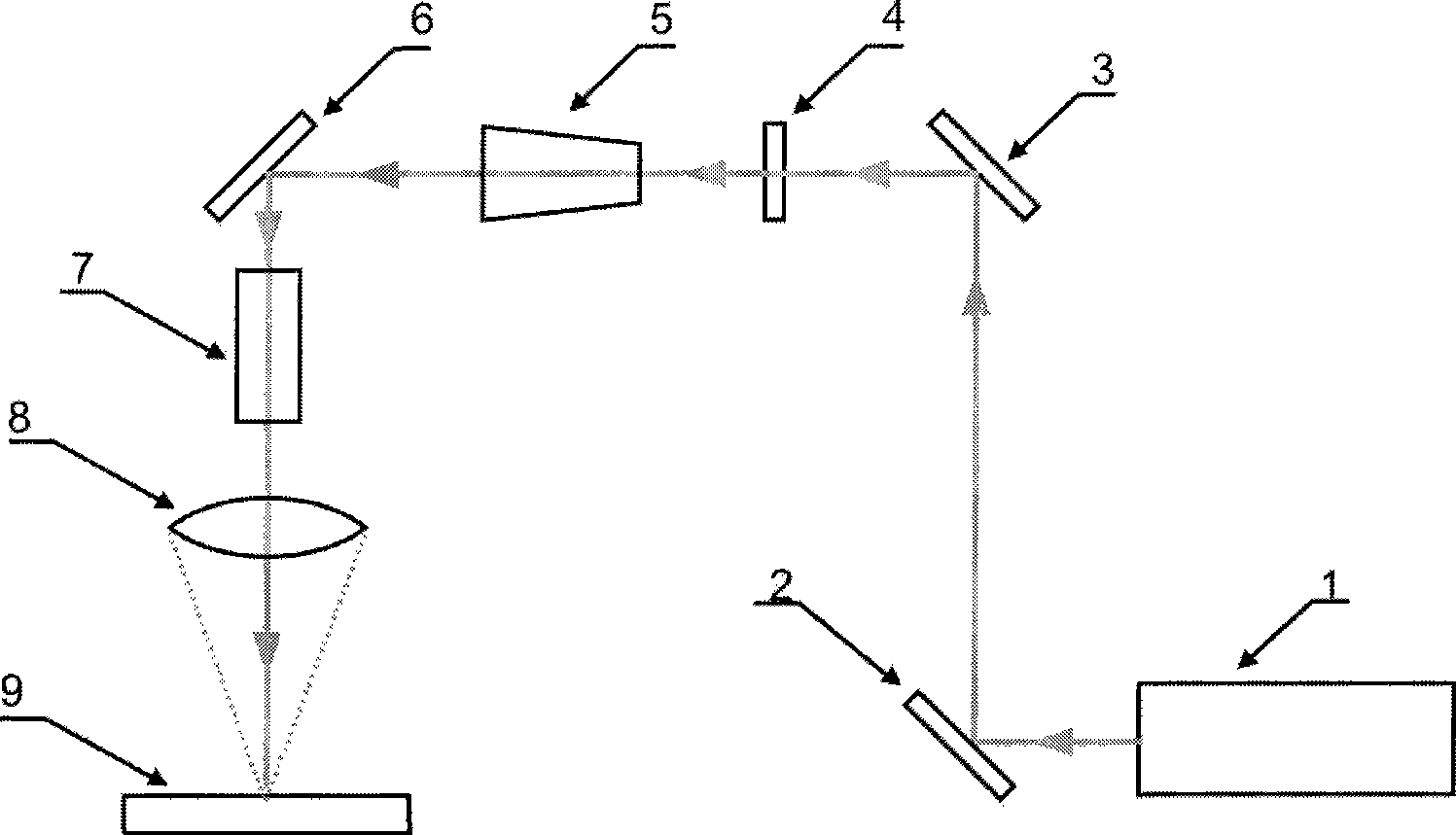

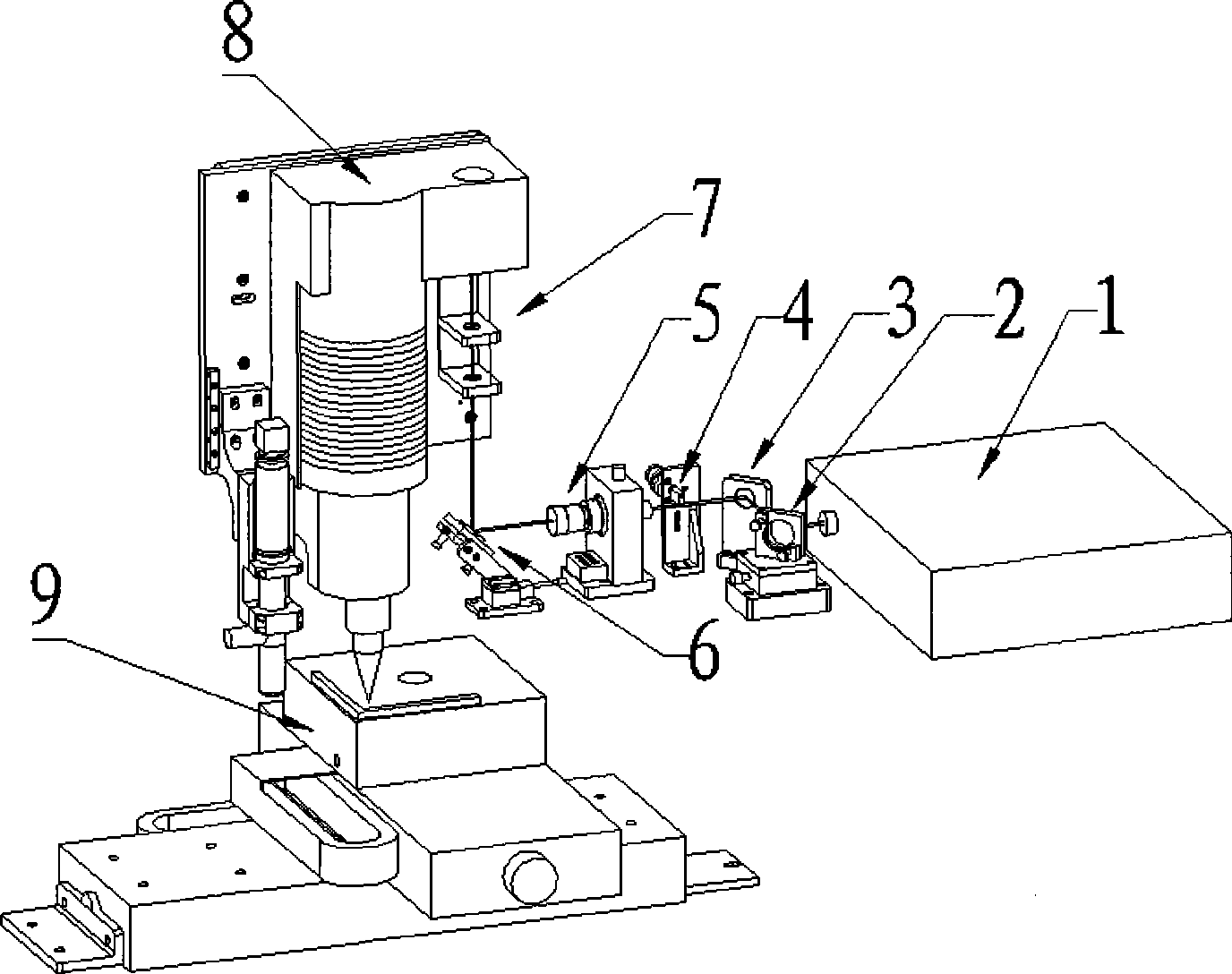

[0016] The invention designs a laser microhole processing device, which uses picosecond laser and spiral optical processing system to process the microholes on the fuel injection nozzle. The picosecond laser enters the spiral optical processing system after optical transmission and calibration system, and is controlled by software. The helical optical system focuses the beam for micro-hole processing.

[0017] Such as figure 1 , figure 2 As shown, the picosecond laser processing device for microhole processing of fuel injectors includes a picosecond laser 1, a calibration system 7, and a spiral optical processing system 8. The output end of the picosecond laser 1 is arranged with a first mirror 2, and the second A reflector 2 is connected to the second reflector 3, and the output end of the second reflector 3 is provided with an optical gate 4, and the output end of the optical gate 4 is connected with a beam expander 5, and the output end of the beam expander 5 is connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com