Edible packaging film and preparation method thereof

A packaging film and food-friendly technology, applied in food preparation, sustainable packaging, packaging, etc., can solve the problems of not having high oil resistance, oxygen resistance, moisture resistance performance, and unsatisfactory comprehensive mechanical properties at the same time, to achieve Facilitate mechanized continuous operation, improve humidity sensitivity, and enhance the effect of elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

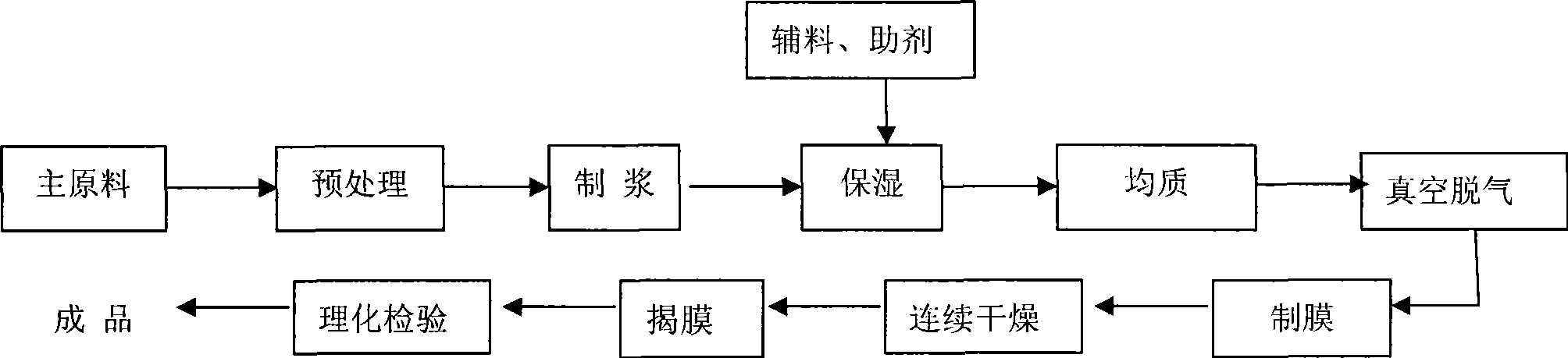

Method used

Image

Examples

Embodiment 1

[0030] Recipe: Gansu Potato Starch 80.0 parts

[0031] Carboxymethylcellulose 15.0 parts

[0032] Carboxymethyl ethyl cellulose 3.0 parts

[0033] Carboxymethylpropyl cellulose 2.0 parts

[0034] Artemisia seed gum 0.5 parts

[0035] 0.5 parts of gelatin

[0036] Glycerin 3.0 parts

[0037] Sunflower oil 2.0 parts

[0038] 1.3 parts corn germ oil

[0039] 0.2 parts of glyceryl diacetate

[0040] Glyceryl triacetate 0.2 parts

[0041] Glyceryl monostearate 0.3 part

[0042] Sucrose ester 0.1 parts

[0043] Preparation method: 1000g of Gansu potato starch starch is equivalent to weighing 80 parts. After pretreatment, add 32L of water to completely dissolve the starch, stir at 90°C for 30 minutes until it dissolves and gelatinizes, moisturizes, and adds additives in the formula amount; Quality: 2000r / min, continuous 5min; vacuum degassing, vacuum degree is 0.095MPa; stainless steel membrane machine film production → continuous drying for 30min, temperature 80-90℃,...

Embodiment 2

[0045] Recipe: Gansu Potato Modified Refined Starch 60.0 parts

[0046] Carboxymethylcellulose 4.0 parts

[0047] Carboxymethyl ethyl cellulose 10.0 parts

[0048] Carboxymethylpropyl cellulose 0.4 parts

[0049] Artemisia seed gum 5.0 parts

[0050] Gum Arabic 2.7 parts

[0051] Glycerin 18.0 parts

[0052] Corn germ oil 15.0 parts

[0053] Diacetin 0.3 parts

[0054] Glyceryl triacetate 1.0 parts

[0055] Glyceryl monostearate 0.2 parts

[0056] 2 parts sucrose ester

[0057] Lecithin 0.01 parts

[0058] Preparation method: 1000g of Gansu potato refined starch is equivalent to weighing 60 parts. After pretreatment, add 28L of water to completely dissolve the starch, stir at 50°C for 20 minutes until it dissolves and gelatinizes, moisturizes, and adds additives in the formula amount; Quality: 1500r / min, continuous 1min; vacuum degassing, the vacuum degree is 0.095MPa; stainless steel film making d...

Embodiment 3

[0060] Recipe: Gansu potato starch 30.0 parts

[0061] Carboxymethylpropyl cellulose 8.0 parts

[0062] Carboxymethyl ethyl cellulose 1.2 parts

[0063] Carboxymethylcellulose 3.0 parts

[0064] Artemisia seed gum 5.0 parts

[0065] Bone glue 0.5 parts

[0066] Gum Arabic 8.0 parts

[0067] Glycerin 22.0 parts

[0068] 2.5 parts corn germ oil

[0069] Palm oil 0.5 parts

[0070] Tributyl citrate 0.3 parts

[0071] Glyceryl triacetate 0.5 parts

[0072] Glyceryl monostearate 0.5 parts

[0073] 1.2 parts of sucrose ester

[0074] Preparation method: 1000g of Gansu potato refined starch is equivalent to weighing 40 parts. After pretreatment, add 30L of water to completely dissolve the starch, stir at 60°C for 40 minutes until dissolved and gelatinized, and add the additives in the formula amount; Quality: 1800r / min, continuous 2min; vacuum degassing, vacuum degree is 0.095MPa; stainless steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com