Secondary battery material

A technology of carbon materials and negative electrode materials, applied in the field of secondary battery materials, can solve problems such as limiting the maximum capacity of lithium-ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

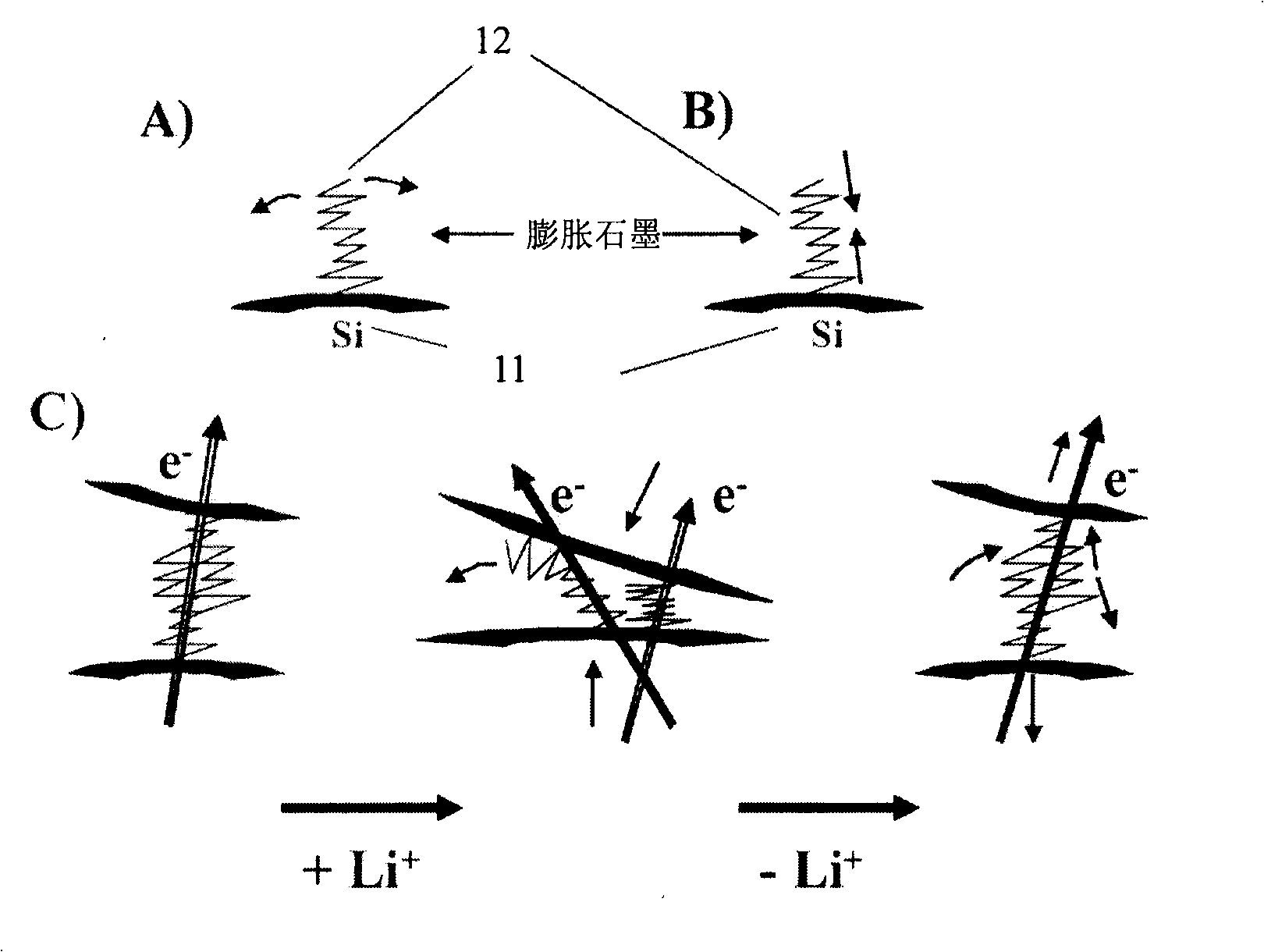

[0066] Expanded graphite-silicon composites with added pre-intercalated graphite

[0067] Expanded graphite-silicon composites were prepared using pre-expanded graphite by a conventional solid-state method. Silicon powder (Si, Aldrich, <30 μm) and carbon pitch powder (CP) were pre-mixed for 12 hours with specific weight ratios, respectively 88% Si and 12% CP, and 92% Si and 8% CP (Wheaton Modular Cell Production Roller Apparatus, Model III).

[0068] The above mixture was further divided into two groups and mixed with expanded graphite (EG, Asbury) in the following weight ratios, 10% EG and 3% EG (each relative to 100% by weight of Si-CP mixture). These four final Si-CP-EG mixtures (see Table 1 for details of samples 1-4) were held for 1 hour, i.e., (88% Si-12% CP) 3% EG, (88% Si -12% CP) 10% EG, (92% Si-8% CP) 3% EG, and (92% Si-8% CP) 10% EG. This step is called one-step firing.

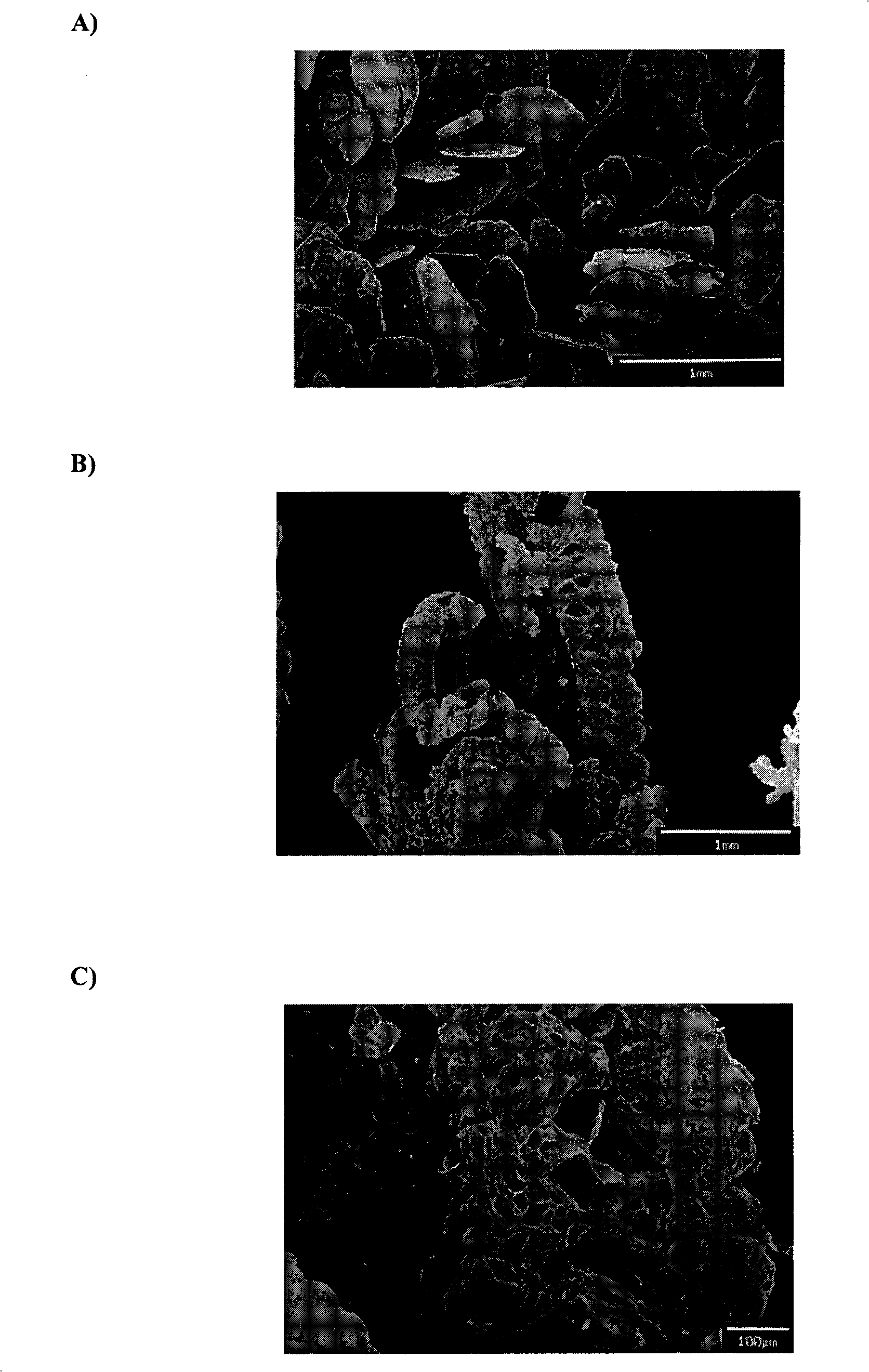

[0069] The above calcined material was passed through a 53-90 μm sieve (Octagon 200 Test Si...

Embodiment 2

[0071] Expanded graphite silicon composites with added pre-expanded graphite

[0072] The expanded graphite-silicon composite material using pre-expanded graphite was prepared by a conventional solid-state method. Silicon powder (Si, Aldrich, <30 μm) and carbon pitch powder (CP) were premixed for 12 hours at specific weight percentages, 88% Si and 12% CP, and 92% Si and 8% CP, respectively (Wheaton Modular Cell Production Roller Apparatus, Model III).

[0073] Each of the above premixed Si-CPs was subjected to the first firing in Ar gas under the condition that the heating rate was increased from room temperature to 400 °C at a rate of 2 °C / min and kept for 1 h, and then cooled to room temperature. The preheated mixture of each Si-CP mixture was divided into two groups and then mixed with expanded graphite (EG) at the same weight percent of EG as the one-step fired sample in Example 1. These four Si-CP-EG mixtures (see Table 1 for details of samples 5-8) were subjected to fi...

Embodiment 3

[0078] Expanded graphite-silicon composites with added pre-intercalated graphite

[0079] Expanded graphite silicon composites were prepared using intercalated graphite by the same method as the solid phase method described in Example 1.

[0080] Silicon powder (Si, Alfa Aesar, 0.05–5 μm), pre-intercalated graphite (IG, Asbury) and carbon pitch powder (CP) were mixed for 12 hours at specific weight percentages, namely 92% Si, 8% CP and 10% IG, wherein the total weight of Si and CP is 100% (Wheaton Modular Cell Production Roller Apparatus, Model III). Then, the above-mentioned mixed mixture was divided into three groups, and preheated respectively under the condition that the heating rate was increased from room temperature to 300, 350, and 400° C. (respectively marked as sample 9, sample 10) at a rate of 4° C. / min. and sample 11), then cooled to room temperature. Then, the preheated mixture was subjected to a final calcination under Ar (CM Furnace 1218) gas from room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com