Copper-based powder metallurgy high speed brake lining

A copper-based powder, high-speed technology, used in friction linings, railway braking systems, mechanical equipment, etc., can solve the problems of large wear, low friction coefficient and high temperature, and achieve good high temperature stability, low material performance, The effect of a high coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

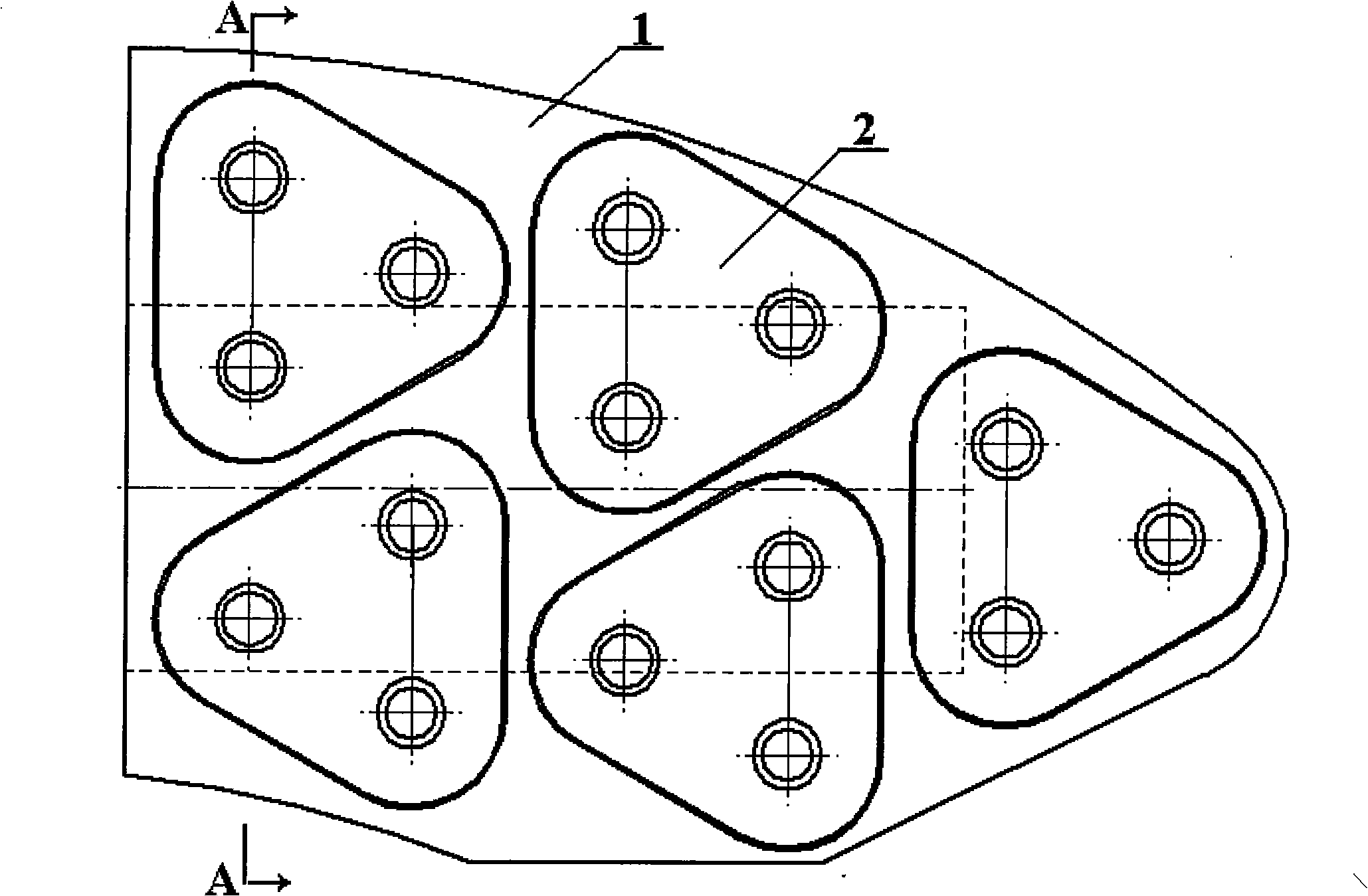

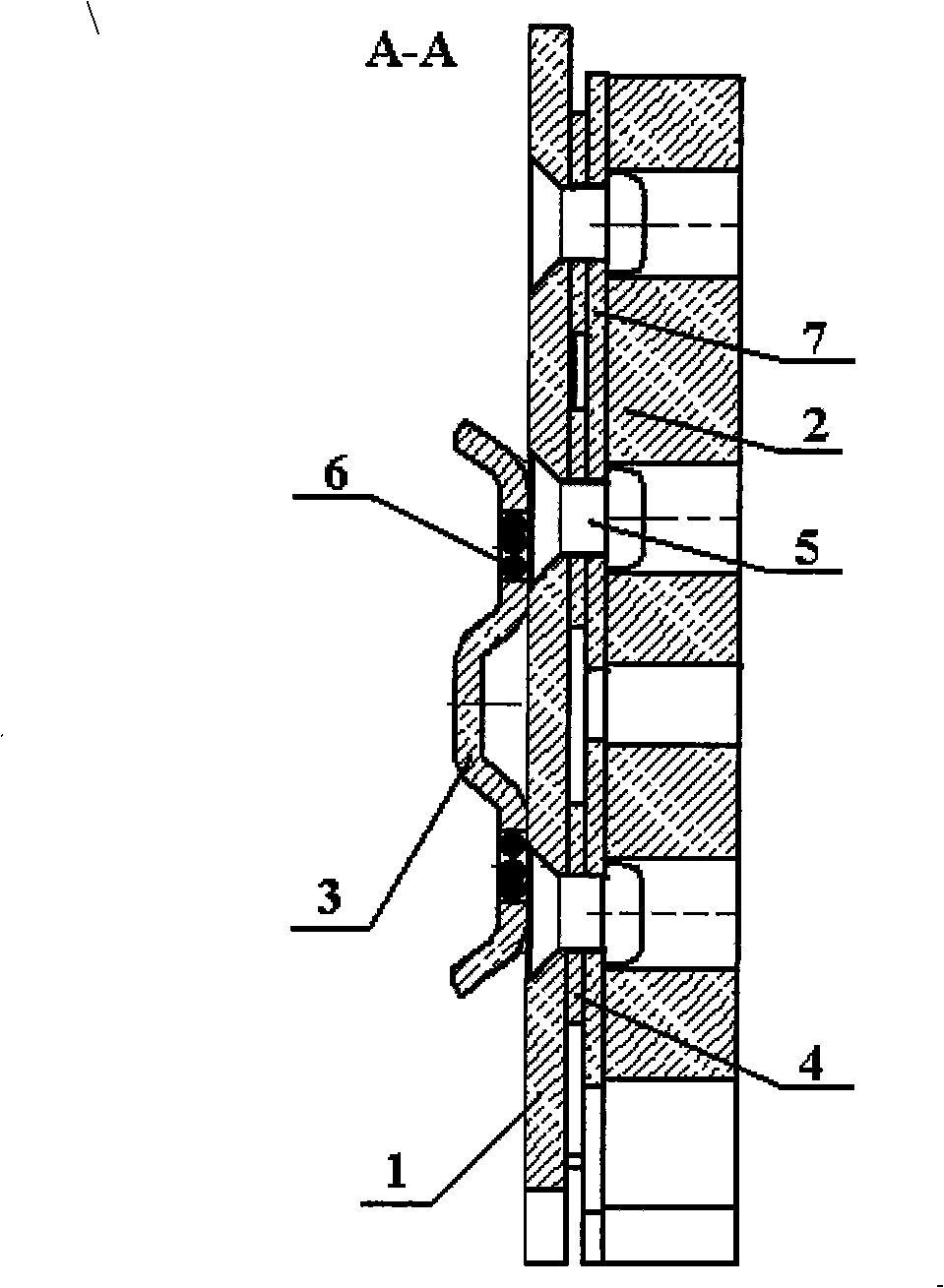

[0021] The present invention is mainly made of steel back 1, brake block 2, dovetail block 3, elastic gasket 4, rivet 5, below in conjunction with attached figure 1 And attached figure 2 One embodiment of the present invention will be described in detail, and of course the embodiment is not the only one. According to this description, those skilled in the art can reproduce the copper-based powder metallurgy high-speed brake pad provided by the present invention without any creative work.

[0022] Fifteen through holes are processed on the steel back 1, and each through hole is chamfered on the same side to fix the skeleton 7, the elastic gasket 4 and the brake block 2 to the steel back 1 through hole without chamfering by using the rivet 5. One side of the corner, so as not to make the rivet head protrude above the surface of the steel back 1; three through holes are processed on the skeleton 7 that are suitable for the position and diameter of the through hole of the steel b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com