Method for joint production of ammonium sulphate and calcium carbonate with phosphogypsum

A technology of phosphogypsum and ammonium sulfate, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, ammonia compounds, etc., can solve the problems of high production cost, complex ammonia synthesis process, low calcium carbonate content, etc. Liquid contact area, the effect of improving the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

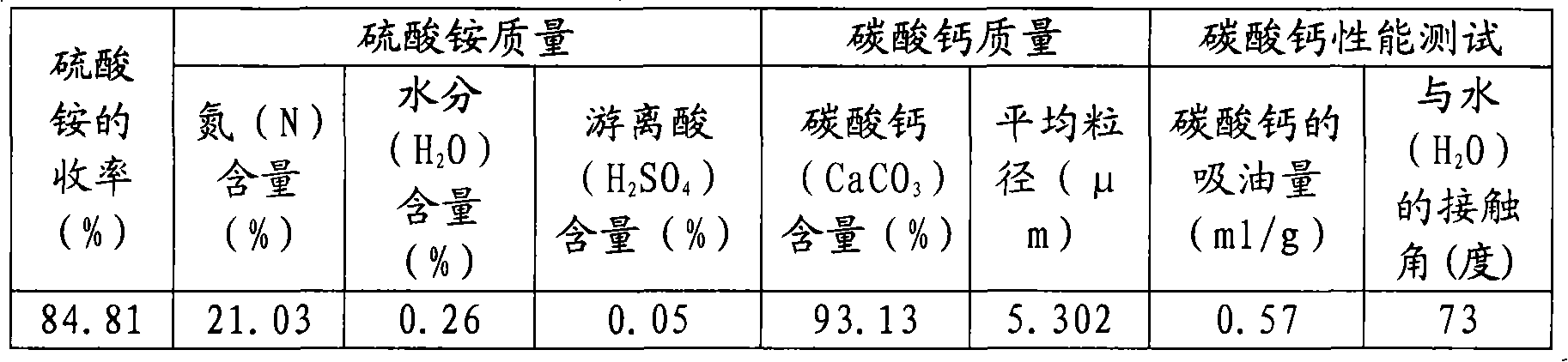

Embodiment 1

[0014] The method for utilizing phosphogypsum to co-produce ammonium sulfate and calcium carbonate may further comprise the steps:

[0015] (1) Phosphogypsum, the waste of high-concentration phosphate fertilizer production, is processed through pulping, rinsing, sedimentation, and screening to obtain phosphogypsum with an average particle size of 20 μm and a whiteness of 75, and make a slurry containing 30% phosphogypsum (phosphorus Calcium sulfate dihydrate content in gypsum is 94.5%), get 6.07kg and join in the reaction kettle that stirring device and heating device are housed, start stirring device, be warming up to 35 ℃, adjust the speed of mixer to be 60 rev / min, add fatty alcohol Disodium polyoxyethylene ether sulfosuccinate monoester 1.34g; add 23% (NH 4 ) 2 CO 3 4.18kg of the solution (the molar ratio of ammonium carbonate and calcium sulfate is 1:1), continue stirring for 1h; turn off the heating and stirring device, drop to room temperature, filter, adjust the pH o...

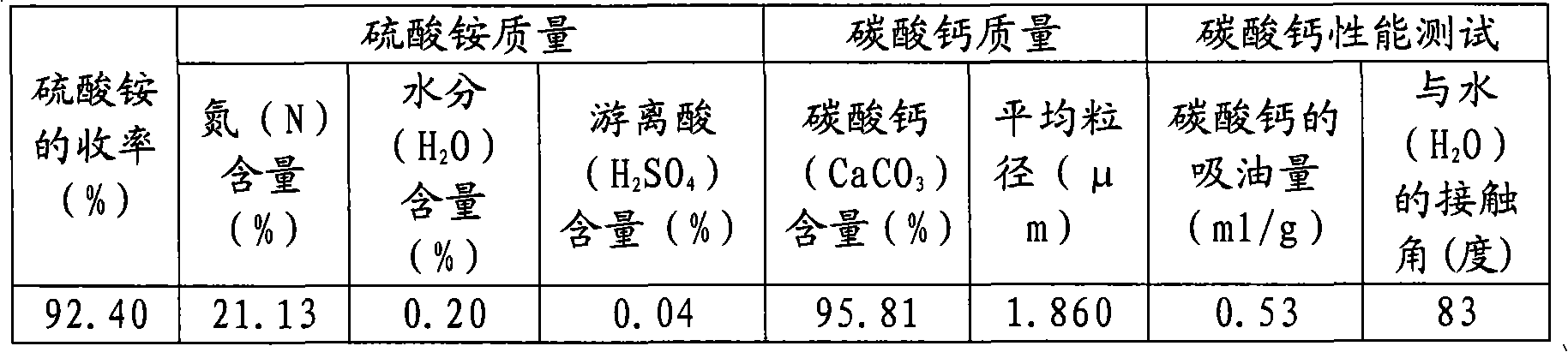

Embodiment 2

[0020] The method for utilizing phosphogypsum to co-produce ammonium sulfate and calcium carbonate may further comprise the steps:

[0021] (1) The waste phosphogypsum produced from the production of high-concentration phosphate fertilizers undergoes pulping, rinsing, sedimentation, and screening to obtain phosphogypsum with an average particle size of 100 μm and a whiteness of 85 to make a slurry of 40% phosphogypsum (phosphogypsum Calcium sulfate dihydrate content is 92.7%), gets 4.64kg and joins in the reaction kettle that stirring device and heating device are housed, starts stirring device, is warming up to 40 ℃, adjusts the speed of mixer to be 200 revs / min, adds stearic acid Polyethylene glycol (10000) ester 8.3g; Add containing 25.2%% (NH 4 ) 2 CO 3 4.19kg of the solution (the molar ratio of ammonium carbonate and calcium sulfate is 1.1:1), continue to stir for 1.5h; turn off the heating and stirring device, drop to room temperature, filter, adjust the pH=5.5 of the ...

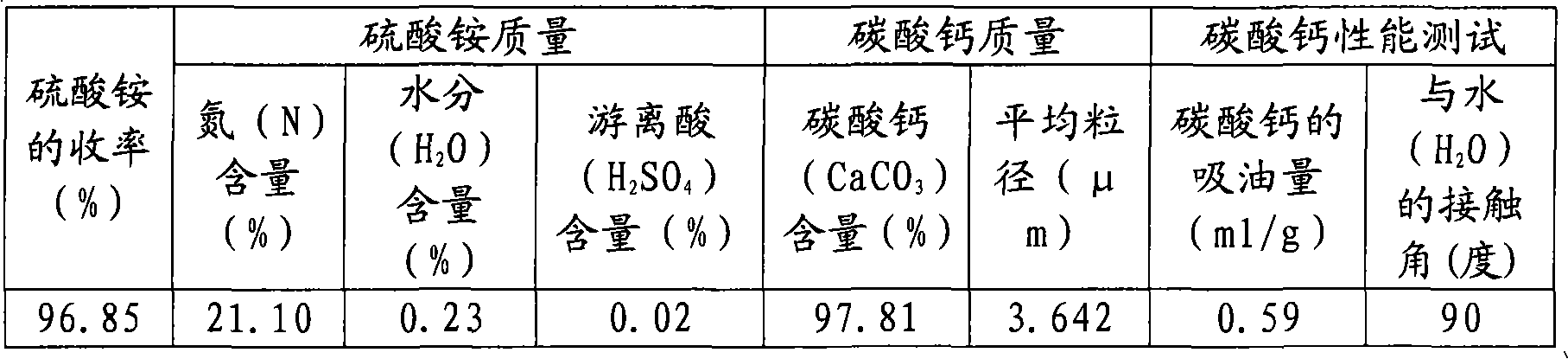

Embodiment 3

[0026] The method for utilizing phosphogypsum to co-produce ammonium sulfate and calcium carbonate may further comprise the steps:

[0027] (1) Phosphogypsum, the waste of high-concentration phosphate fertilizer production, undergoes pulping, rinsing, sedimentation, and screening to obtain phosphogypsum with an average particle size of 70 μm and a whiteness of 80 to make a slurry of 35% phosphogypsum (phosphogypsum Calcium sulfate dihydrate content is 93.9%), gets 5.24kg and joins in the reactor that stirrer and heating unit are housed, starts stirrer, is warming up to 40 ℃, adjusts the speed of mixer to be 100 rev / min, adds coconut oil Disodium monoethanolamide sulfosuccinate monoester 3.0g; add 25% (NH 4 ) 2 CO 3 4.04kg of the solution (the molar ratio of ammonium carbonate and calcium sulfate is 1:1.05), continue stirring for 1.5h; turn off the heating and stirring device, drop to room temperature, filter, adjust the pH of the filtrate=5.78, and obtain (NH 4 ) 2 SO 4 C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com