Preparation method of vulcanization type hydrogenation catalyst

A technology of hydrogenation catalyst and sulfurizing agent, which is applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. problems, to achieve the effect of low preparation cost, avoid metal aggregation, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation of embodiment 1 catalyst carrier

[0037]Take by weighing 900g of pseudo-boehmite (produced by Tianjin Alumina Factory, dry basis is 73%), 19g of scallop powder, 32g of citric acid, 48ml of nitric acid (30%), 159ml of silica gel (containing 30% of silicon dioxide), and remove Mix 250ml of deionized water evenly, extrude into 1.2mm clover strips on the extruder, dry at 120°C for 4 hours, and roast at 600°C for 3 hours to obtain carrier A. The specific surface area of carrier A is 324.5m 2 / g, the pore volume is 0.72cm 3 / g, the average pore diameter is 8.87nm, and the intensity is 186N / cm.

Embodiment 2

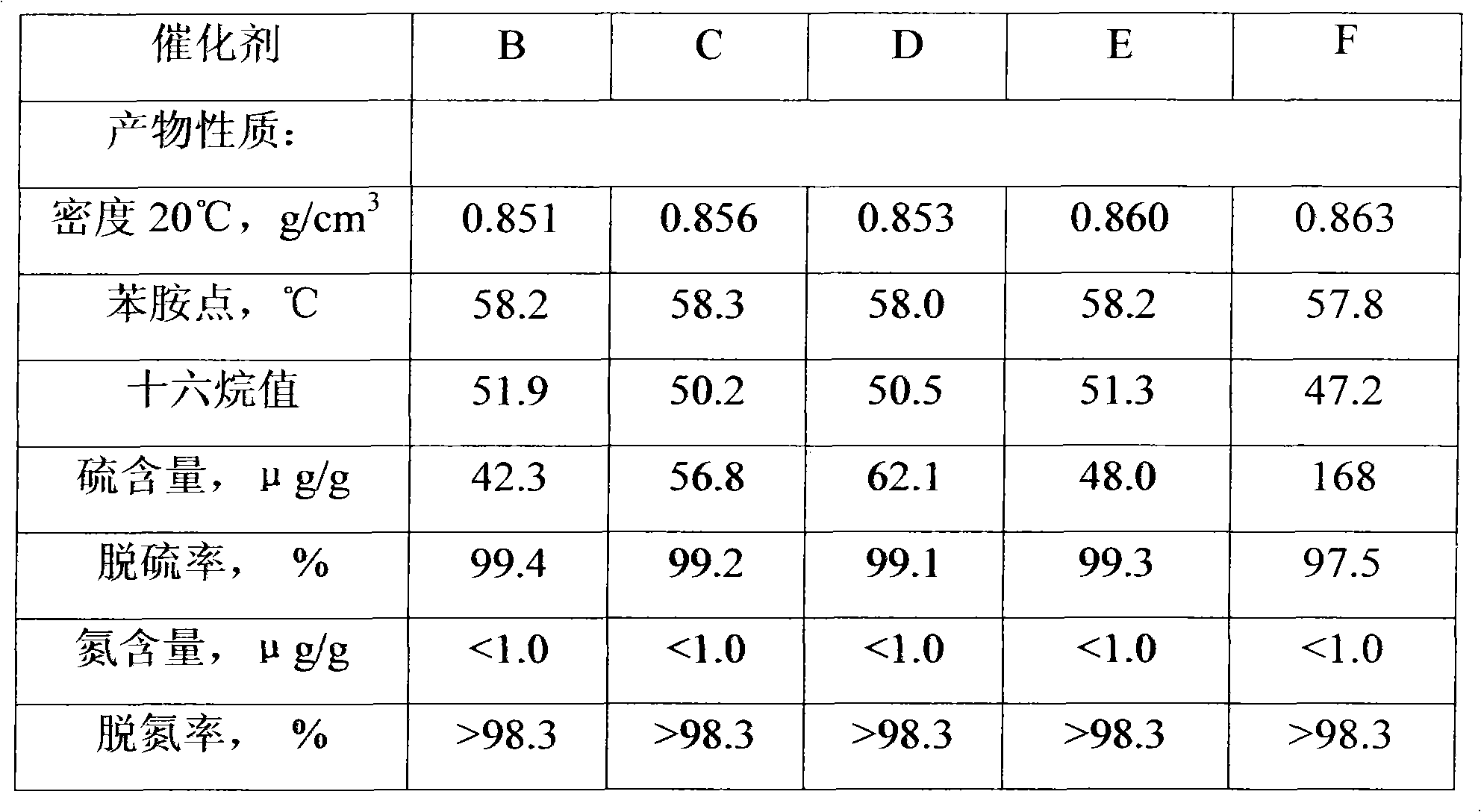

[0038] The preparation of embodiment 2 sulfurized catalyst B

[0039] Weigh 28.48g of molybdenum oxide, 8.9g of basic nickel carbonate, add 60ml of deionized water and mix well, add 4ml of 85% phosphoric acid, heat to 75°C, and keep the temperature for 1 hour to obtain a dark green clear and transparent solution, then add 30.2g of partial tungsten Stir the ammonium acid to obtain the impregnating solution 1 after dissolving. According to the water absorption rate of 74ml / 100g, take the impregnating solution 1, spray and impregnate the carrier A, and heat-treat at 160°C for 3 hours to obtain a low-temperature heat-treated sample. Take the same amount of ammonium sulfide and phosphoric acid (85%) as the impregnating solution and flow-spray the low-temperature heat-treated sample , (NH 4 ) 2 S and H 3 PO 4 The mass ratio of catalyst B is 10:1, heat treatment at 160°C for 3 hours to obtain catalyst B, the main physical properties are shown in Table 1.

Embodiment 3

[0040] The preparation of embodiment 3 sulfurized catalyst C

[0041] Get impregnating solution 1 and ammonium sulfide in Example 2 and spray and impregnate carrier A according to water absorption rate 74ml / 100g, the volume ratio of impregnating solution 1 and ammonium sulfide is 1: 1, heat treatment at 200 ℃ for 5 hours, obtains catalyst C, The main physical properties are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com