Rubbish drying machine

A dryer and garbage technology, applied in dryers, drying solid materials, drying gas layout, etc., can solve problems such as low energy utilization rate, achieve high energy conversion efficiency, fast drying, and eliminate environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

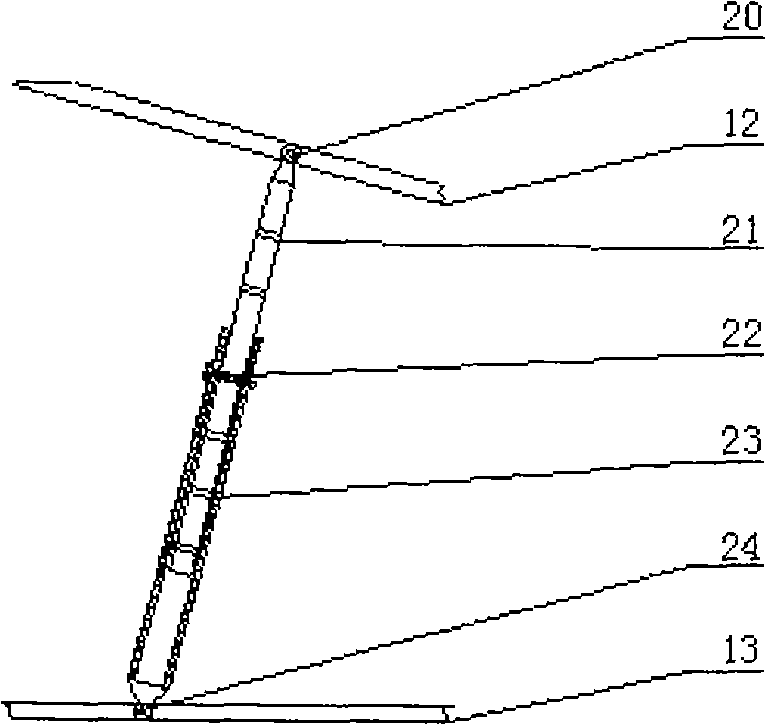

[0021] see figure 1 , the present invention consists of a feed hopper 2, a screw propeller 1, a discharge pipe 16, a material delivery pipe 3, a rotary transmission device, an angle adjustment device, a microwave cavity 4, a microwave generator 5, a microwave choke 6, and an air distribution pipe 17 , an air inlet pipe 7, an air outlet pipe 8 and a heat pump machine 9. The feeding end of the material conveying pipe 3 is connected with the feeding hopper 2, and the discharging end passes through the microwave cavity 5 and connects with the discharging tube 16. Its main part is located in the microwave cavity 4, and the feeding end is inclined higher than the discharging end. set up. The screw propeller 1 is installed on the feeding end of the material conveying pipe 3, and is used to enhance the power of the garbage moving from the feeding end to the discharging end. There are three microwave generators 5, which are installed in the microwave cavity 4 inclined at the same ang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com