Industrial production method for directly producing iron and vanadium-titanium-aluminum alloy from vanadium-titanium magnet placer

A vanadium-titanium magnet and production method technology, applied to the improvement of process efficiency, furnace type, furnace, etc., can solve the problems of high production cost and difficult operation, and achieve high production efficiency, no environmental pollution, social benefits and economic benefits significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

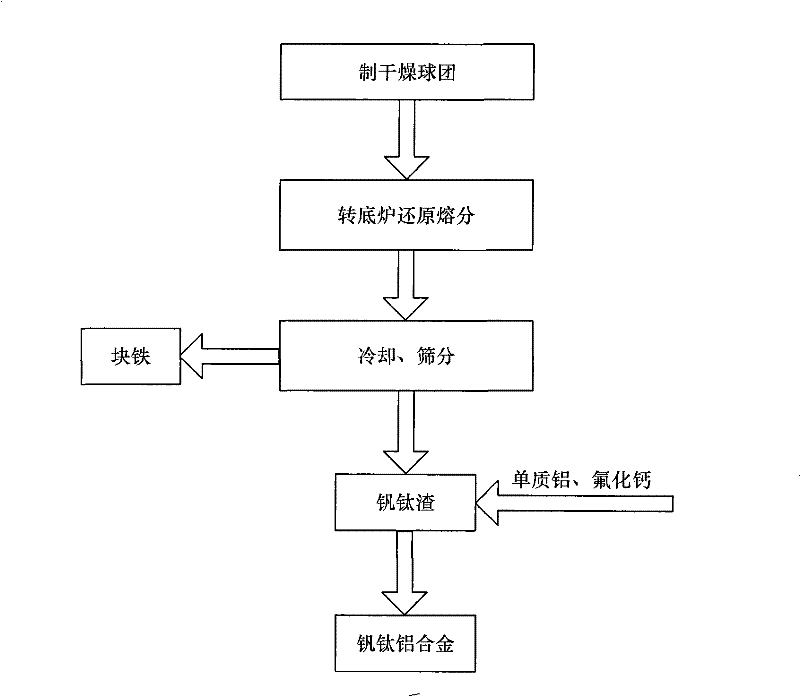

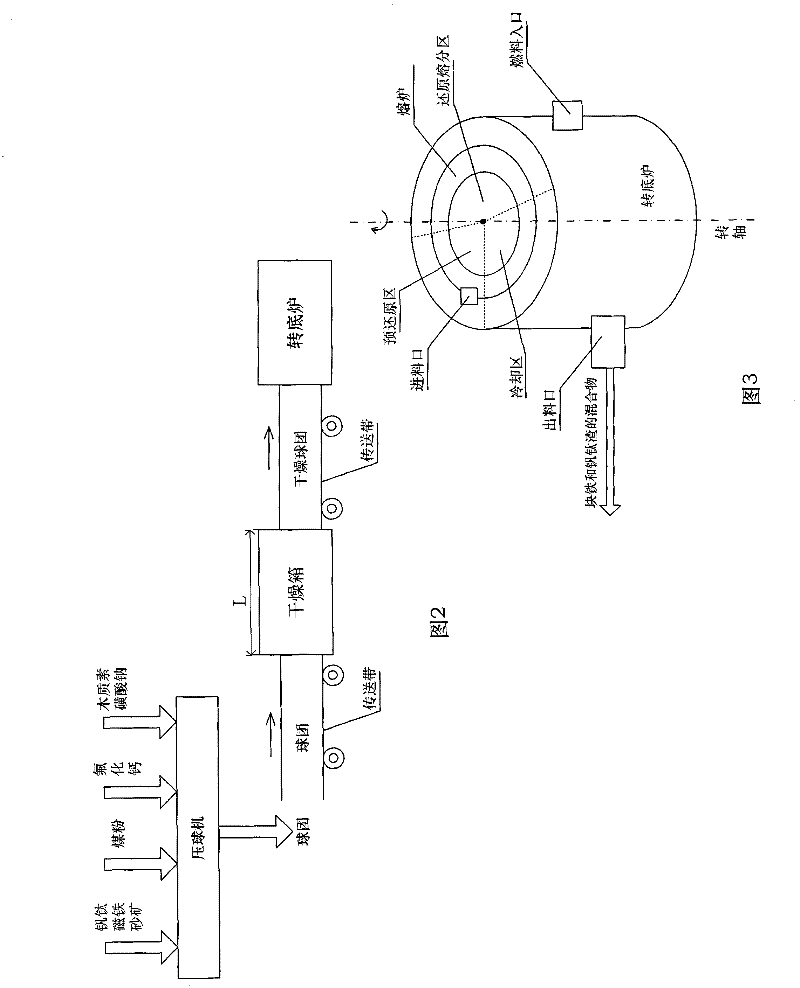

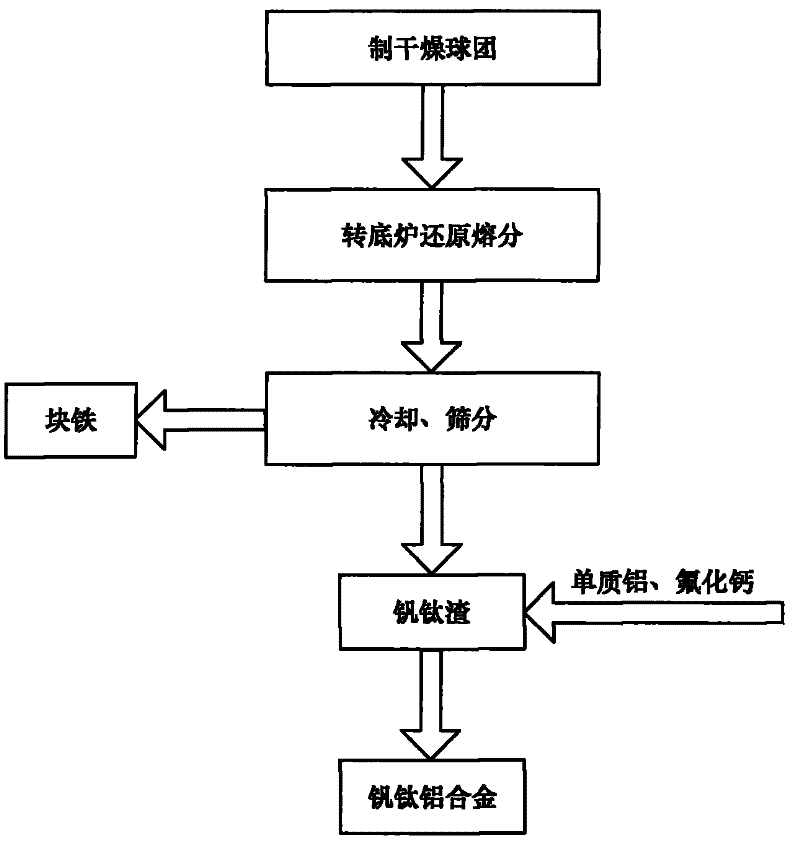

Method used

Image

Examples

Embodiment 1

[0060] The vanadium-titanium magnetite placer (80% of the placer particle size is less than 0.2mm) is collected from the Ulan area of Indonesia abroad. The main components are FeO content of 27.73%, Fe 2 o 3 The content is 47.73%, TiO 2 The content is 14.01%, V 2 o 5 The content is 0.66%, SiO 2 The content of MgO is 2.5%, the content of MgO is 2.1%, the content of CaO is 3.2% and the rest of impurities (impurities refer to trace amounts of S, P).

[0061] The industrial production preparation steps of producing lump iron and vanadium-titanium-aluminum alloy from the vanadium-titanium magnetite sand ore collected from the Ulan area of Indonesia are as follows:

[0062] Step 1: Use the ball pressing mechanism to pellet

[0063] Stir the vanadium-titanium magnetite ore, coal powder, calcium fluoride, and sodium lignosulfonate evenly, and then use a briquetting machine to make pellets with a diameter of 20mm;

[0064] The pressure required for the briquetting mechanism t...

Embodiment 2

[0082] The vanadium-titanium magnetite placer (87% of the placer's particle size is less than 0.4mm) was collected in Wuding, Yunnan, and the main components FeO content is 29.13%, Fe 2 o 3 The content is 50.43%, TiO 2 The content is 7.72%, V 2 o 5 The content is 0.59%, SiO 2 The content of MgO is 3.1%, the content of MgO is 3.0%, the content of CaO is 3.0% and the rest of impurities (impurities refer to trace amounts of S and P).

[0083] The industrial production steps for producing lump iron and vanadium-titanium-aluminum alloy from the vanadium-titanium magnetite sand ore collected in Wuding area of Yunnan Province are as follows:

[0084] Step 1: Use the ball pressing mechanism to pellet

[0085] Mix vanadium-titanium magnetite ore, coal powder, calcium fluoride, and sodium lignosulfonate evenly, and then use a briquette machine to produce pellets with a diameter of 60 mm;

[0086] The pressure required for the briquetting mechanism to pelletize is 30MPa.

[0087...

Embodiment 3

[0103] The vanadium-titanium magnetite sand ore (particle size less than 0.4mm) collected from the Caga area of Luzon, Philippines, mainly consists of 24.38% FeO, 24.38% Fe 2 o 3 Content is 55.19%, TiO 2 The content is 13.42%, V 2 o 5 The content is 0.59%, SiO 2 The content of MgO is 1.7%, the content of MgO is 1.0%, the content of CaO is 1.0% and the rest of impurities (impurities refer to trace amounts of S and P).

[0104] The industrialized production steps for producing lump iron and vanadium-titanium-aluminum alloy from the vanadium-titanium magnetite sand ore collected in Lusong Kaga, Philippines are as follows:

[0105] Step 1: Use the ball pressing mechanism to pellet

[0106] Stir the vanadium-titanium magnetite ore, coal powder, calcium fluoride, and sodium lignosulfonate evenly, and then use a briquette machine to produce pellets with a diameter of 50 mm;

[0107] The pressure required for the briquetting mechanism to pelletize is 25MPa.

[0108] Dosage: A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com