Industrial production method for directly producing iron and vanadium-titanium-aluminum alloy from iron concentrate

A production method and technology for iron concentrate are applied in the field of vanadium-titanium-aluminum alloy production, which can solve the problems of difficult operation and high production cost, and achieve the effects of no environmental pollution, high production efficiency, and easy industrialization promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The iron concentrate extracted from the vanadium-titanium magnetite ore in Chengde, Hebei is used.

[0061] The iron concentrate (80% of the particle size is less than 0.076mm) is mainly composed of FeO content of 27.73%, Fe 2 o 3 The content is 48.13%, TiO 2 The content is 10.02%, V 2 o 5 The content is 0.66%, SiO 2 The content of MgO is 3.5%, the content of MgO is 4.1%, the content of CaO is 3.2% and the rest of impurities (impurities refer to trace amounts of S, P).

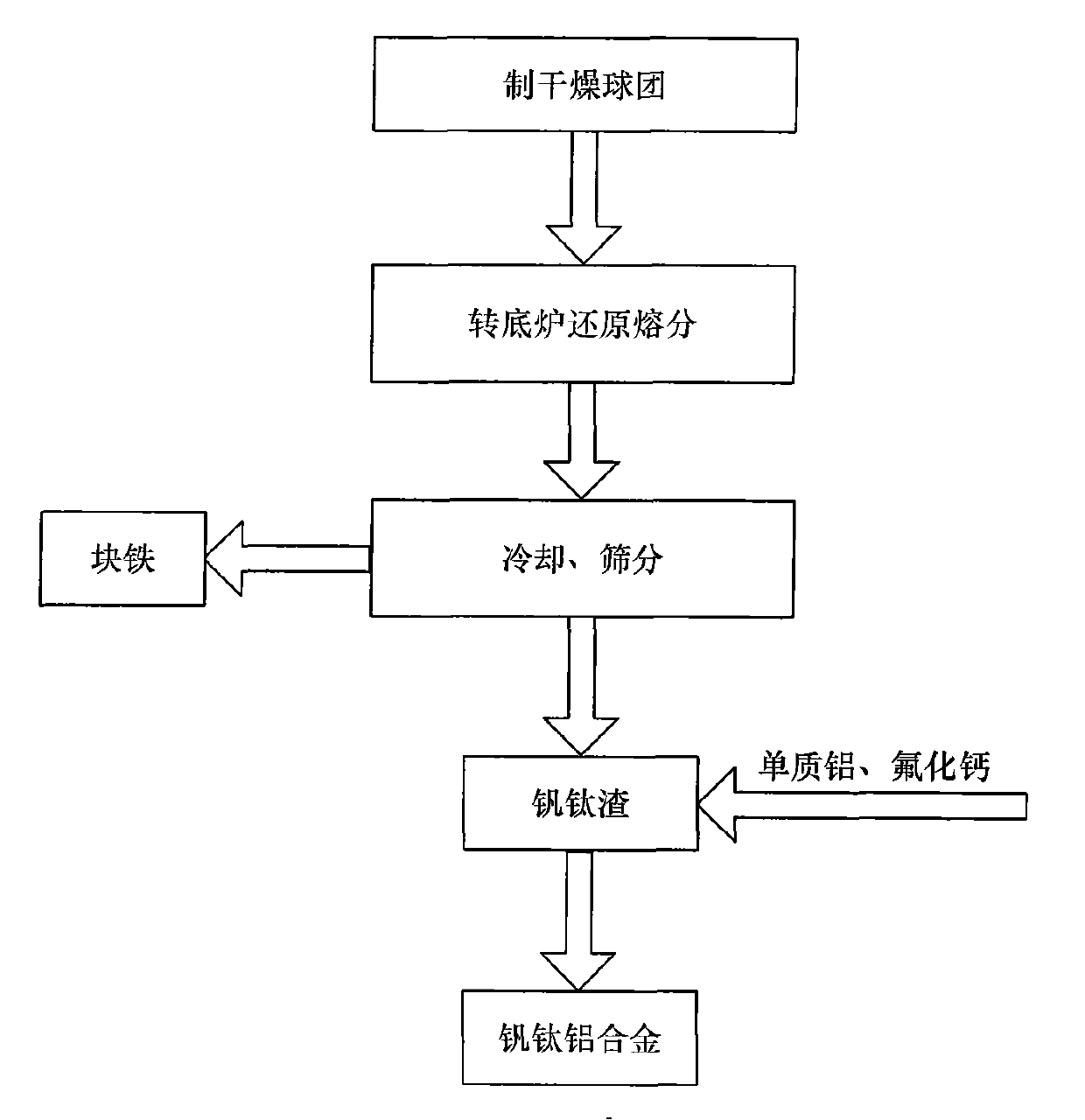

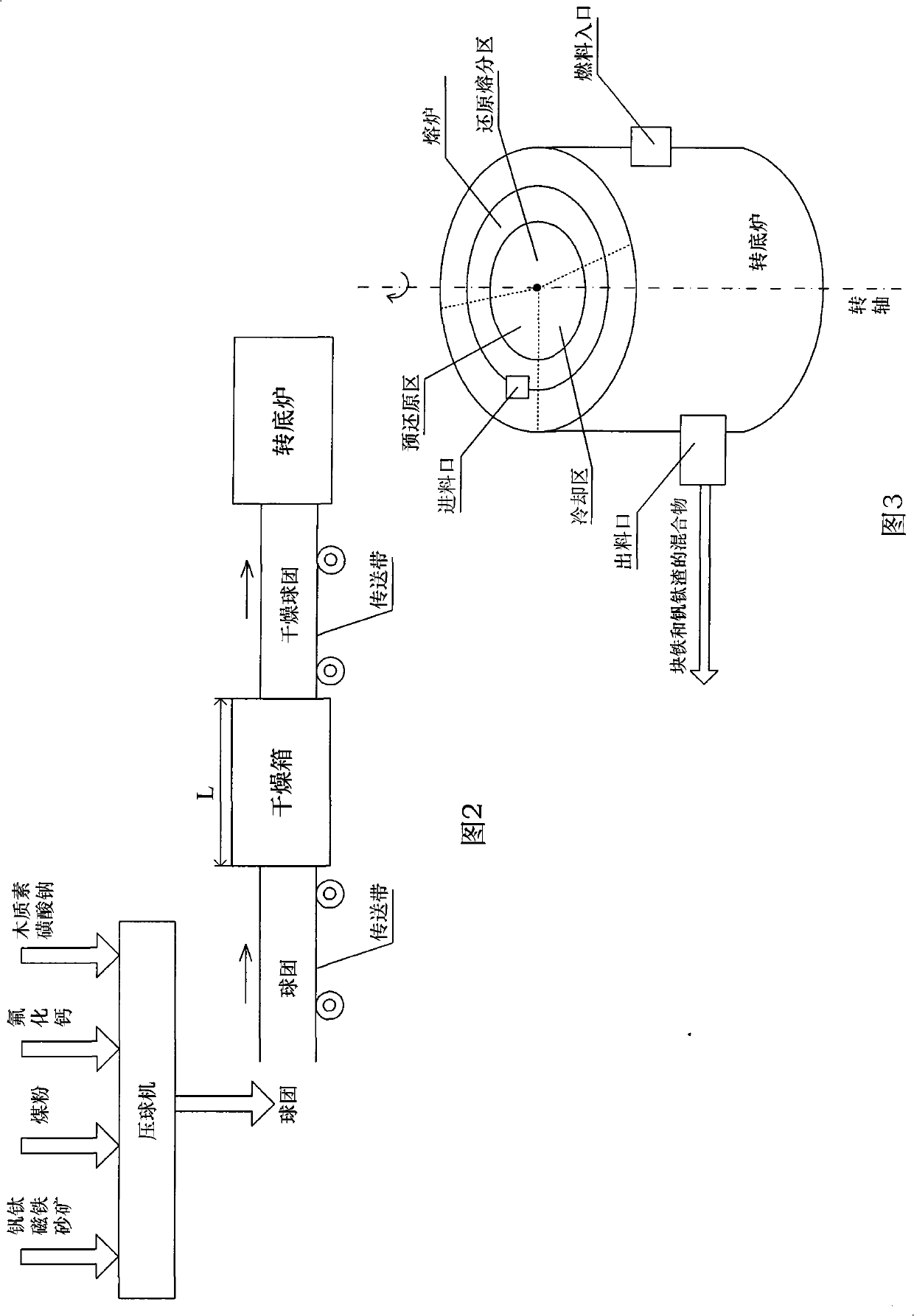

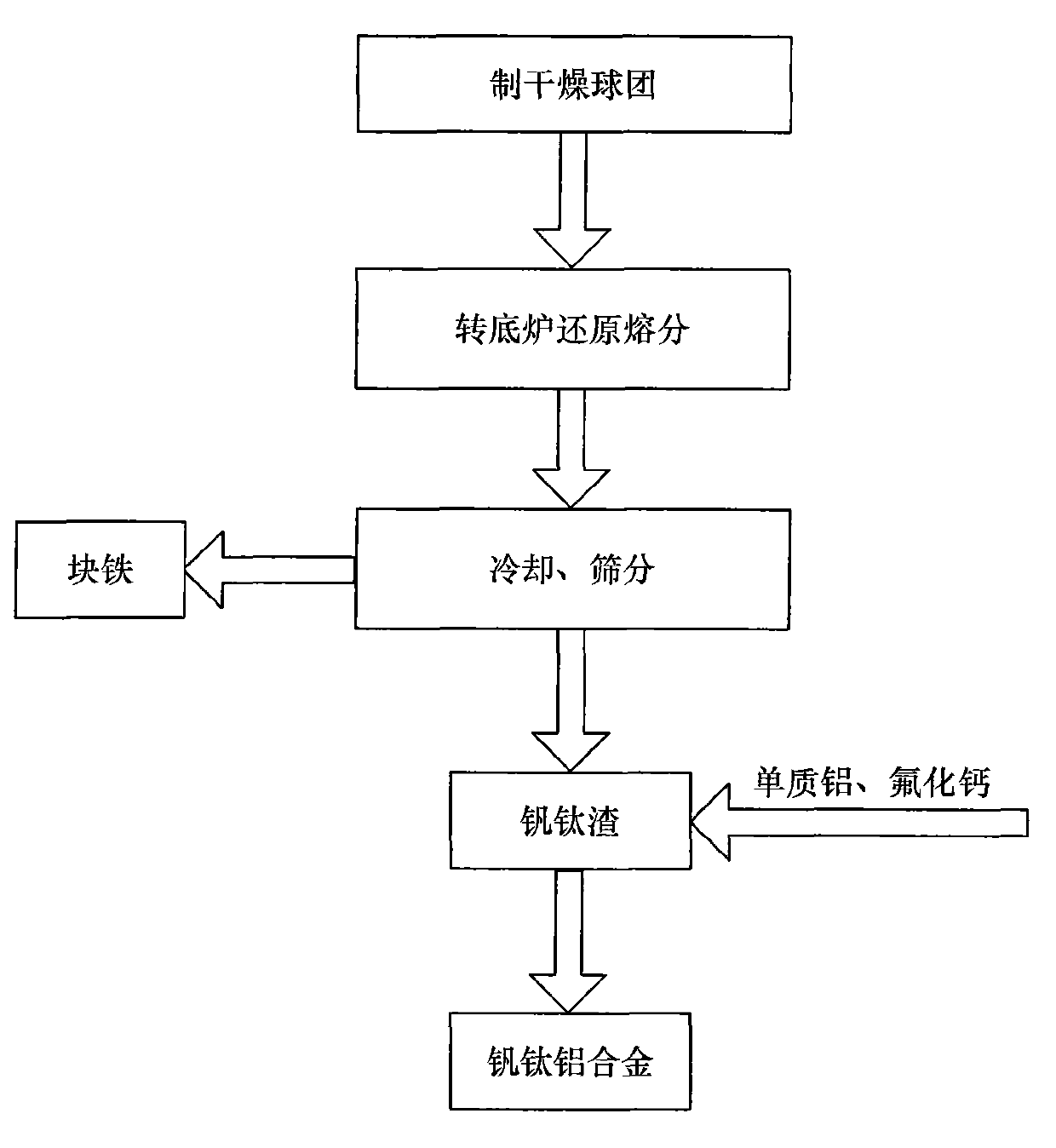

[0062] The industrial production preparation steps of using iron concentrate to produce lump iron and vanadium-titanium-aluminum alloy are as follows:

[0063] Step 1: Use the ball pressing mechanism to pellet

[0064] After stirring iron concentrate, coal powder, calcium fluoride and sodium lignosulfonate evenly, pellets with a diameter of 20 mm are produced through a briquetting machine;

[0065] The pressure required for the briquetting mechanism to pelletize is 25MPa.

[0066] Dosage: Add 25...

Embodiment 2

[0083] Iron concentrate extracted from vanadium-titanium magnetite ore in Panzhihua, Sichuan.

[0084] The iron ore concentrate (87% of the particle size is less than 0.1mm) has a main component FeO content of 29.13%, Fe 2 o 3 The content is 43.43%, TiO 2 The content is 14.52%, V 2 o 5 The content is 0.59%, SiO 2 The content of MgO is 3.1%, the content of MgO is 3.0%, the content of CaO is 3.0% and the rest of impurities (impurities refer to trace amounts of S and P).

[0085] The industrial production preparation steps of producing lump iron and vanadium-titanium-aluminum alloy from iron concentrate are as follows:

[0086] Step 1: Use the ball pressing mechanism to pellet

[0087] After stirring the iron concentrate, coal powder, calcium fluoride and sodium lignosulfonate evenly, the pellets with a diameter of 60 mm are obtained through a briquetting machine;

[0088] The pressure required for the briquetting mechanism to pelletize is 30MPa.

[0089] Dosage: Add 150g...

Embodiment 3

[0105] Iron concentrate extracted from vanadium-titanium magnetite ore in Linyi, Shandong.

[0106] The iron ore concentrate (70% of the particle size is less than 0.4mm) has a main component FeO content of 24.38%, Fe 2 o 3 Content is 55.19%, TiO 2 The content is 13.42%, V 2 o 5 The content is 0.59%, SiO 2 The content of MgO is 1.7%, the content of MgO is 1.0%, the content of CaO is 1.0% and the rest of impurities (impurities refer to trace amounts of S and P).

[0107] The industrial production preparation steps of producing lump iron and vanadium-titanium-aluminum alloy from iron concentrate are as follows:

[0108] Step 1: Use the ball pressing mechanism to pellet

[0109] After stirring the iron concentrate, coal powder, calcium fluoride and sodium lignosulfonate evenly, the pellets with a diameter of 50 mm are obtained through a briquetting machine;

[0110] The pressure required for the briquetting mechanism to pelletize is 25MPa.

[0111] Dosage: Add 200g of coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com