Ultra-high purity medium transporting integration process

A pure medium, ultra-high technology, used in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] An ultra-high-purity medium conveying integrated device, consisting of a heat exchanger 11, a cooling water circulation device, and a water-for-injection circulation device, is characterized in that: a pure steam access pipe 12, a first temperature sensor 131, a second The temperature sensor 132 and the control panel 14, the cooling water inlet pipe is connected to the refrigerant inlet of the heat exchanger through the first valve 151, the cooling water outlet pipe is connected to the refrigerant outlet of the heat exchanger through the second valve 152; The three valves 153 are connected to the water-for-injection inlet of the heat exchanger, the water-for-injection inlet pipe is connected to the pure steam inlet pipe 12 through the fourth valve 154, and the water-for-injection outlet pipe is connected to the fifth valve 155; the point of use is through the fifth valve 155 is connected to the water outlet of the water for injection of the heat exchanger; the cooling wa...

Embodiment 2

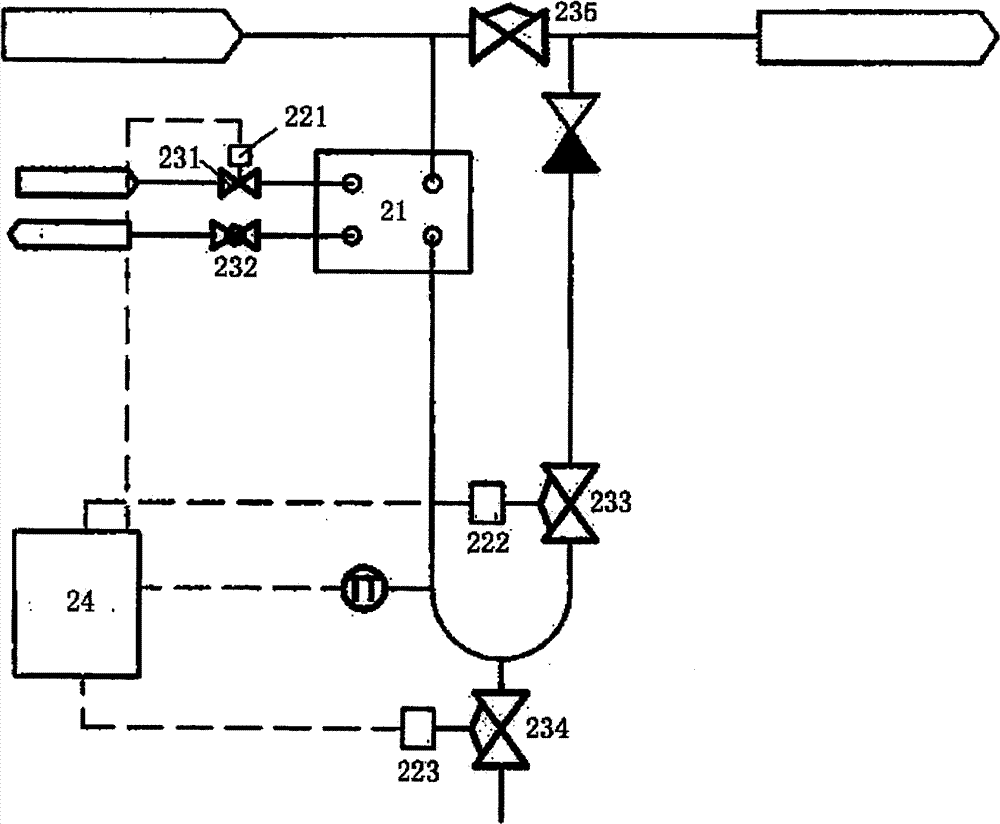

[0027]An ultra-high-purity medium conveying integrated equipment is composed of a heat exchanger 21, a cooling water circulation device, and a water-for-injection circulation device, and a third temperature sensor 221, a fourth temperature sensor 222, a fifth temperature sensor 223, a An automatic valve 231, a second automatic valve 232, a third automatic valve 233, a fourth automatic valve 234, a fifth automatic valve 235 and the control panel 24, the cooling water inlet pipe is connected to the refrigerant of the heat exchanger through the first automatic valve 231 The inlet, the cooling water outlet pipe is connected to the refrigerant outlet of the heat exchanger through the second automatic valve 232: the water for injection water inlet pipe is connected to the water injection water inlet of the heat exchanger, and the water injection water outlet pipe is connected to the water injection water outlet of the heat exchanger , the water outlet pipe of water for injection is c...

Embodiment 3

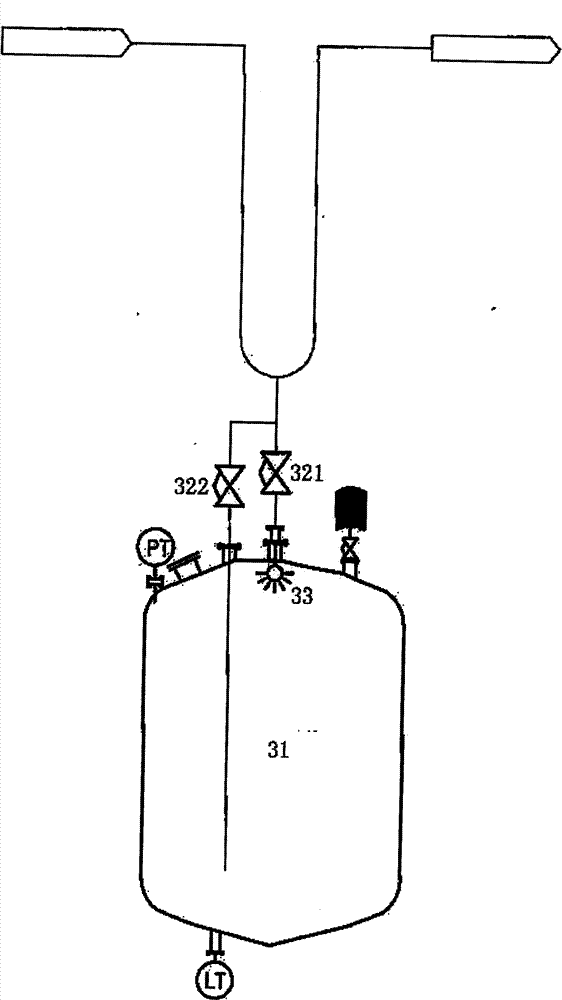

[0029] A batching device such as image 3 As shown, it is composed of a batching tank 31 and a water-for-injection circulation device. The water-for-injection water inlet pipe is divided into two paths, one of which is connected to the spray ball 33 at the top of the batching tank 31 through the valve 321, and the other through the valve 322 with a straight The tube goes directly below the liquid level inside the batching tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com