Method for smelting nickel-iron alloy from laterite nickel oxide ore

A technology for nickel oxide ore and nickel-iron alloy, applied in the field of nickel-iron alloy smelting, can solve the problems of high energy consumption and large amount of slag, and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

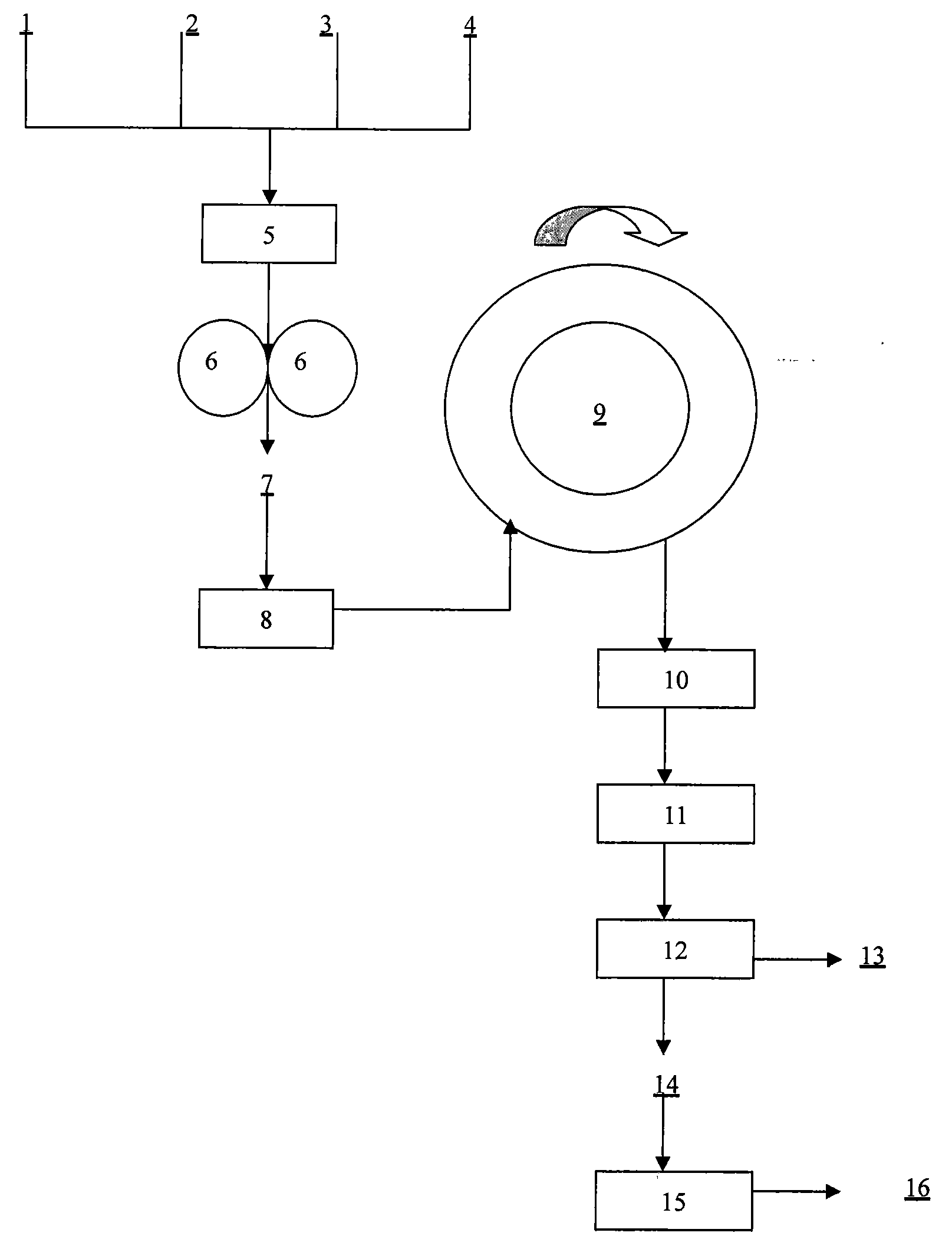

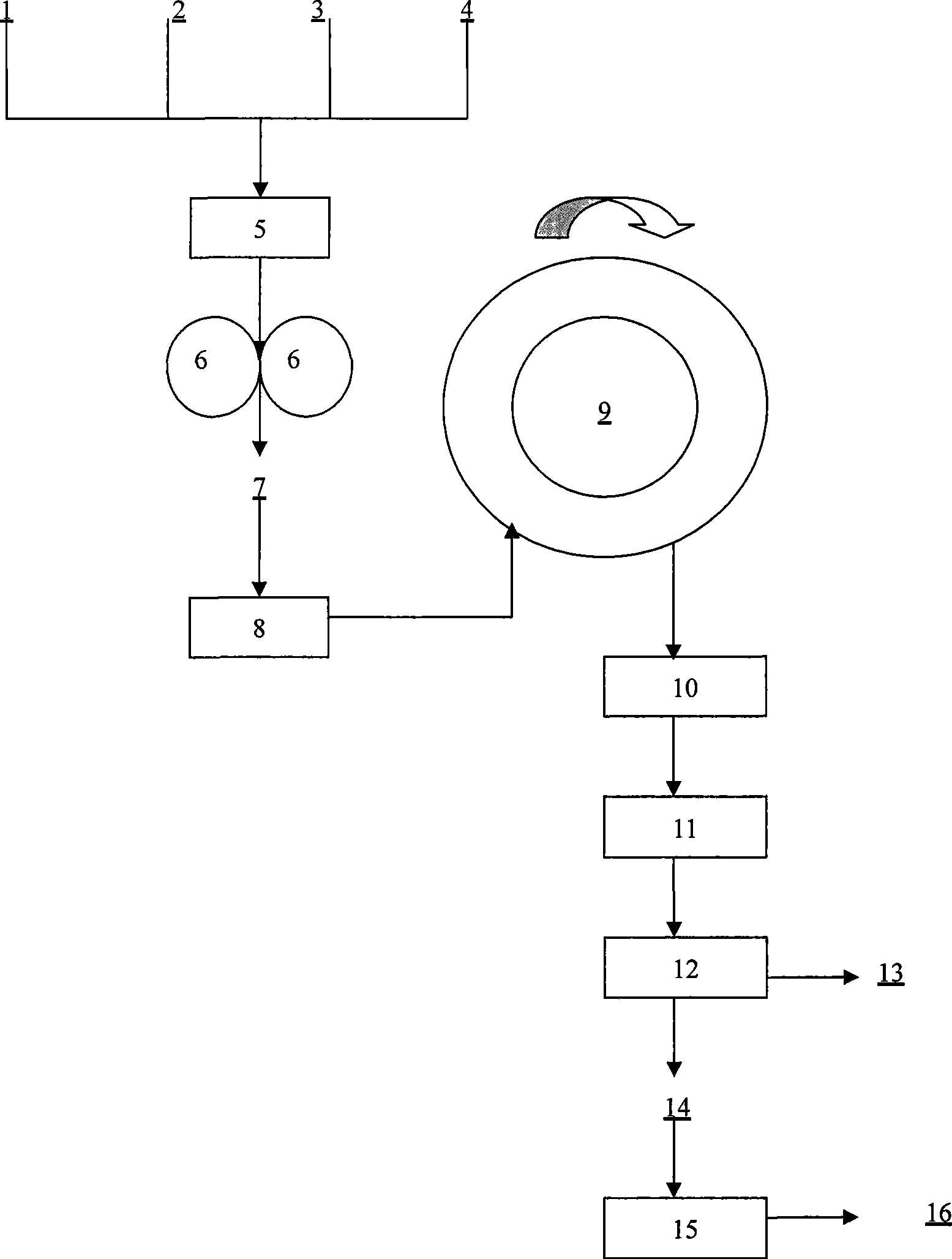

Method used

Image

Examples

Embodiment

[0023] Mix 80% by weight of lateritic nickel oxide ore powder, 5% by weight of coal powder, and 15% by weight of flux to uniformly press the ball. Most of the pellets obtained after reduction, melting and cooling are slag phase, while the granular nickel-iron alloy is embedded in the slag, and its particle size is about 0.5mm~5mm. After water quenching and crushing, magnetic separation, Most of the slag phase is removed, and the obtained magnetic substance is a coarse nickel-iron alloy containing a small amount of slag. Since the ferronickel content in the lateritic nickel oxide ore is only 10% in total and the ratio of metal to slag is low, the liquid ferronickel contained in the slag bears high pressure, and their dispersion degree in the slag is also large, so mutual aggregation is achieved. The distance of diffusion is long, and the chance of collision and contact with each other is small, so smaller granular nickel-iron is often formed according to the principle of proxim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com