UV cured fluorescent color conversion film for electroluminescence display device and preparation

A color conversion and electroluminescence technology, applied in chemical instruments and methods, luminescent coatings, luminescent materials, etc., can solve the problems of low brightness and unsatisfactory conversion efficiency, and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

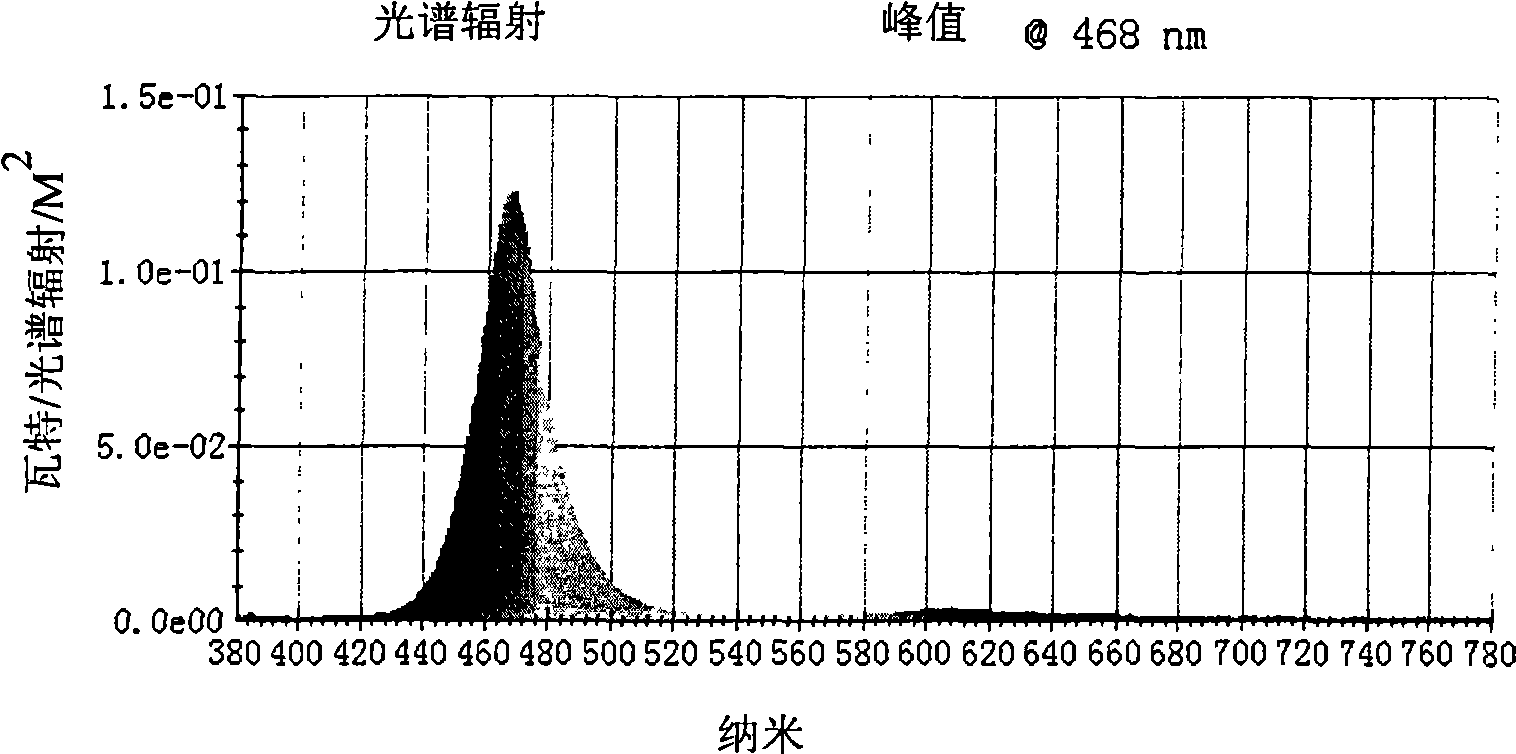

Embodiment 1

[0051]

[0052] Put the reactive diluent, polymer dispersant, and defoamer components into the pulping container, and use a high-speed adjustment disperser to stir for 5-120mins at a speed of 300-1000rmp. Then add the fluorescent pigment in the formulated amount, and stir with a high-speed adjustment disperser for 5-120mins, and the rotation speed is 700-4000rmp. Then add the active oligomer in the formulated amount, and grind with a grinder at a speed of 3000-10000 rpm for 1-24 hours until the fineness of the mixture in the pulping vessel is less than 10 μm. Finally, a photoinitiator dissolved with a certain active monomer is added, and a high-speed disperser is used for high-speed stirring to obtain an ultraviolet-curable organic fluorescent coating for a full-color electroluminescent display. After screen-printing the organic fluorescent paint on the light emitting surface of the electroluminescence display screen, a single-tube medium-pressure mercury lamp is used, and ...

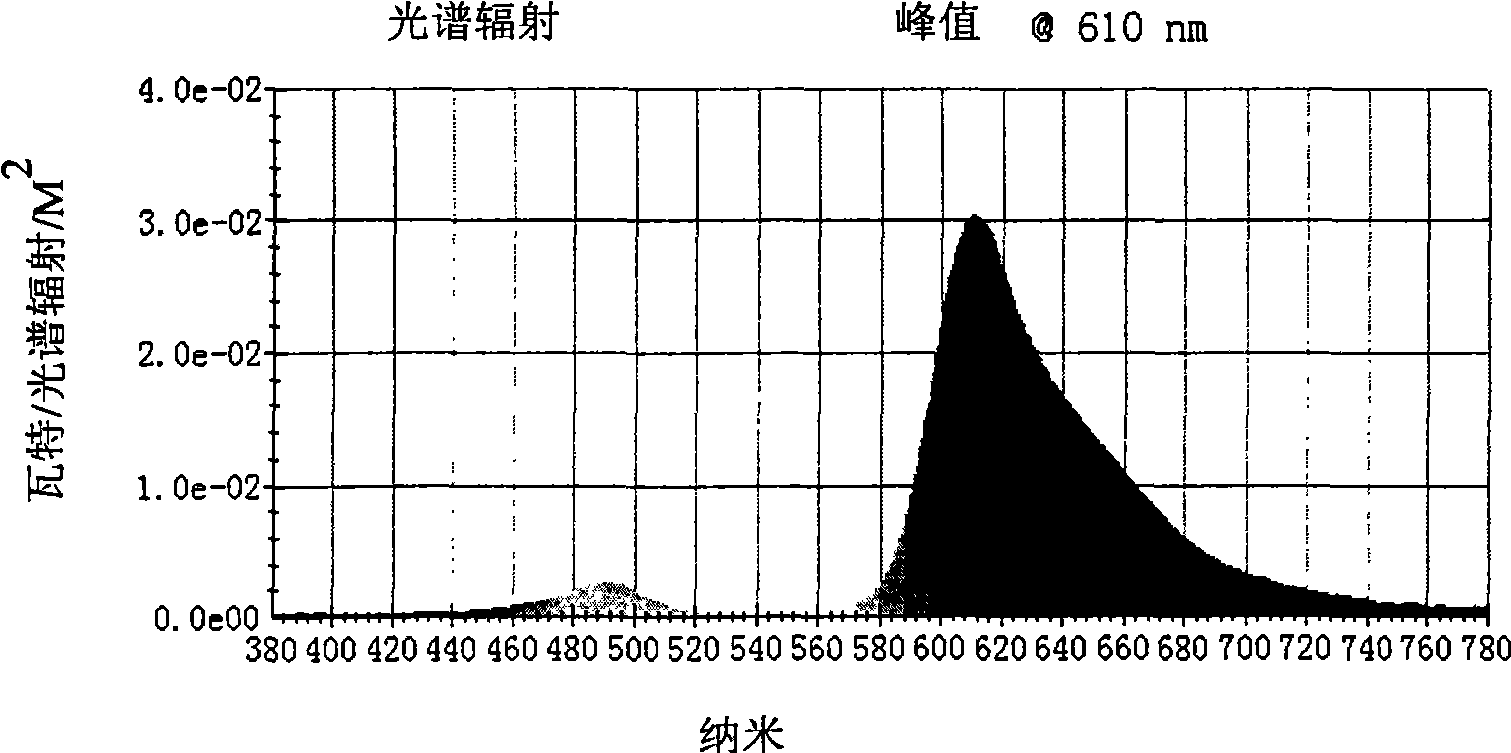

Embodiment 2

[0054]

[0055] Put the reactive diluent, polymer dispersant, and defoamer components into the pulping container, and use a high-speed adjustment disperser to stir for 5-120mins at a speed of 300-1000rmp. Then add the fluorescent pigment in the formulated amount, and stir with a high-speed adjustment disperser for 5-120mins, and the rotation speed is 700-4000rmp. Then add the active oligomer in the formulated amount, and grind with a grinder at a speed of 3000-10000 rpm for 1-24 hours until the fineness of the mixture in the pulping vessel is less than 10 μm. Finally, a photoinitiator dissolved with a certain active monomer is added, and a high-speed disperser is used for high-speed stirring to obtain an ultraviolet-curable organic fluorescent coating for a full-color electroluminescent display. After screen-printing the organic fluorescent paint on the light emitting surface of the electroluminescence display screen, a single-tube medium-pressure mercury lamp is used, and ...

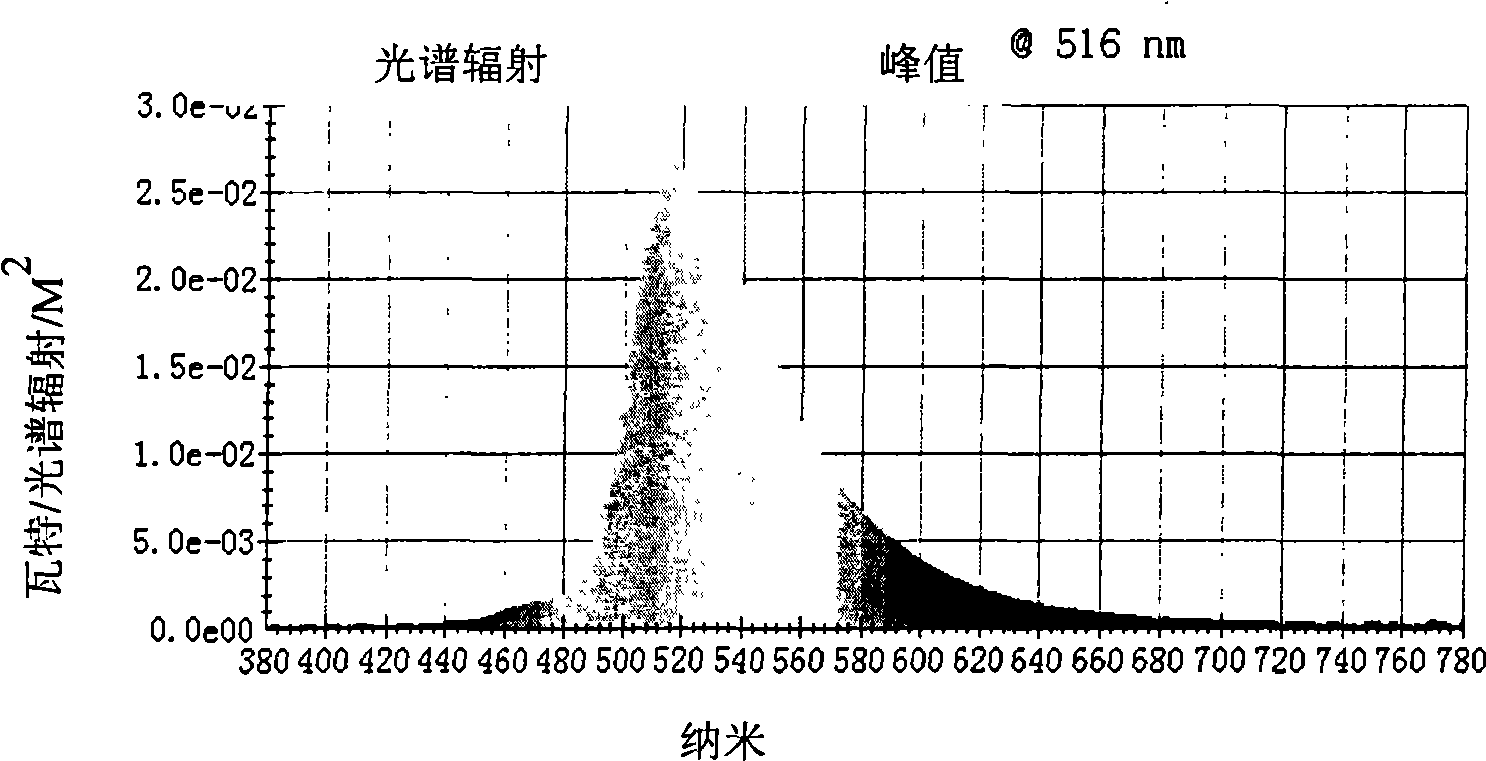

Embodiment 3

[0057]

[0058] Put the reactive diluent, polymer dispersant, and defoamer components into the pulping container, and use a high-speed adjustment disperser to stir for 5-120mins at a speed of 300-1000rmp. Then add the fluorescent pigment in the formulated amount, and stir with a high-speed adjustment disperser for 5-120mins, and the rotation speed is 700-4000rmp. Then add the active oligomer in the formulated amount, and grind with a grinder at a speed of 3000-10000 rpm for 1-24 hours until the fineness of the mixture in the pulping vessel is less than 10 μm. Finally, a photoinitiator dissolved with a certain active monomer is added, and a high-speed disperser is used for high-speed stirring to obtain an ultraviolet-curable organic fluorescent coating for a full-color electroluminescent display. After screen-printing the organic fluorescent paint on the light emitting surface of the electroluminescent display screen, a single-tube medium-pressure mercury lamp is used to cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com