Stalk light body energy-saving heat preserving building blocks and manufacturing method thereof

A technology of thermal insulation block and straw, which is applied in the direction of building structure, building components, construction, etc., can solve the problems of high price, and achieve the effect of low cost, huge economic and social benefits, and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

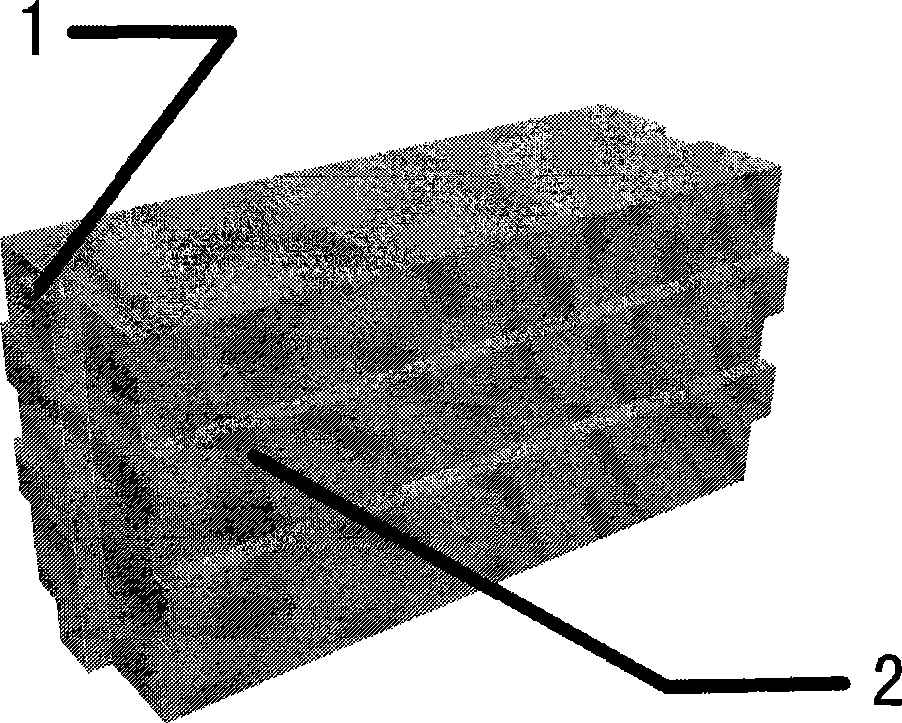

[0014] according to figure 1 with figure 2 As shown, the top surface 1 of the block is provided with a convex groove structure, the strip surface 2 is provided with several raised rib structures in the transverse direction, and the protective layer 3 structure is provided on both sides of the strip surface.

Embodiment 2

[0016] Get 10Kg of high-strength and low-alkali cement; 5Kg of fly ash; 1Kg of superfine active mixed material silica fume; 5Kg of crushed straw (modified PVFM latex surface modifier with low formaldehyde content self-made by surface spraying); ethylene-vinyl acetate copolymer Latex 0.5Kg; waterproof and anti-seepage agent 0.01Kg; preservative 0.01Kg; superplasticizer UNF 0.075Kg; activator 0.5Kg; water 5Kg. Stir evenly, after forming, demoulding and curing, after the block is formed, apply cement waterproof liquid on the outside and maintain to make a finished product.

Embodiment 3

[0018] Get 10Kg of high-strength and low-alkali cement; 1Kg of fly ash; 0.5Kg of superfine active mixed material silica fume; 10Kg of crushed straw (surface spraying self-made low formaldehyde content modified PVFM latex surface modifier); ethylene-vinyl acetate copolymer latex 0.1Kg; waterproof and impervious agent 0.01Kg; preservative 0.01Kg; superplasticizer UNF 0.05Kg; activator 0.05Kg; water 7Kg. Stir evenly, after molding, demoulding, maintenance, after the block is formed, apply cement waterproof liquid on the outside, and make a protective layer on both sides with ordinary Portland cement, sand, slag, UNF high-efficiency water reducing agent and water, and then maintain it. finished product (see figure 1 with figure 2 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com