Aluminum alloy strip assembly for umbrella framework and machining technique thereof

An aluminum alloy strip and processing technology technology, which is applied in the field of aluminum alloy strip material assembly and processing technology for umbrella skeleton, can solve the problem of low tensile strength, poor 180° bending effect, and can not meet the production of high-grade umbrella skeleton. Use and other problems to achieve the effect of excellent mechanical properties and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

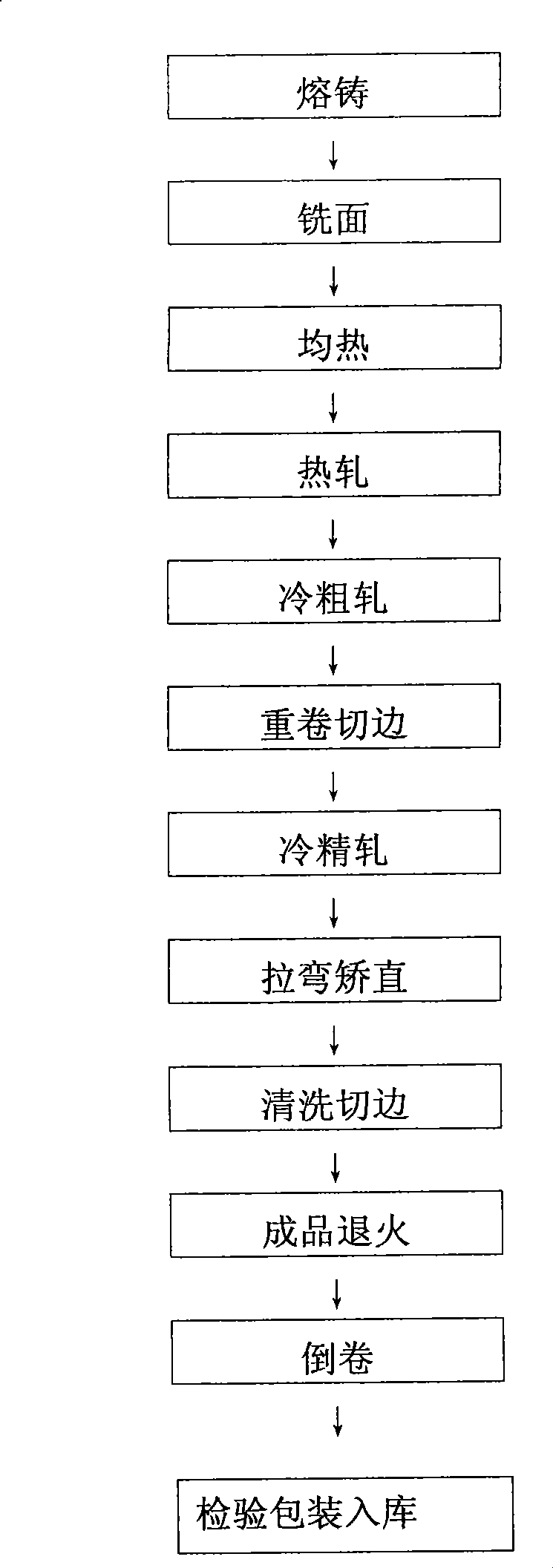

Method used

Image

Examples

Embodiment 1

[0029] 5052H38-0.49×1200mm:

[0030] Melting and casting: Firstly, batching according to weight percentage: Fe: ≤0.35, Si ≤ 0.25, Cu: ≤0.1, Mn: ≤0.1, Mg: 2.3~2.7, Zn: 0.1, Cr: 0.15~0.25, other impurities in total ≤0.15% , the balance is Al; the sum of each component is 100%; the ingredients are smelted in a smelting furnace, and then the chemical composition is tested before being cast into an ingot;

[0031] Face milling: the ingot is milled with a milling machine, the milling amount of the large face of the ingot is 8mm, and the milling amount of the side is 5mm. It is necessary to mill out all kinds of metallurgical defects that affect the subsequent production and the final use performance of the product.

[0032] Heating: Use a heating furnace to heat the milled billet. After the furnace temperature rises to 500-560°C, it turns to a constant temperature and heat preservation: 4-6h. After the billet temperature rises to 450-500°C, the furnace gas drops to 500-530°C. Keep...

Embodiment 2

[0043] 5052H38-0.69×1200mm

[0044] Melting and casting: Firstly, batching according to weight percentage: Fe: ≤0.35, Si≤0.25, Cu: ≤0.1, Mn: ≤0.1, Mg: 2.3-2.7, Zn: 0.1, Cr: 0.15-0.25, other impurities in total ≤0.15% , the balance is Al; the sum of each component is 100%; the ingredients are smelted in a smelting furnace, and then the chemical composition is tested before being cast into an ingot;

[0045] Face milling: the ingot is milled with a milling machine, the milling amount of the large face of the ingot is 12mm, and the milling amount of the side is 8mm. It is necessary to mill out all kinds of metallurgical defects that affect the subsequent production and the final use performance of the product.

[0046] Heating: Use a heating furnace to heat the milled billet. After the furnace temperature rises to 500-560°C, it turns to a constant temperature and heat preservation: 4-6h. After the billet temperature rises to 450-500°C, the furnace gas drops to 500-530°C. Keep war...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com