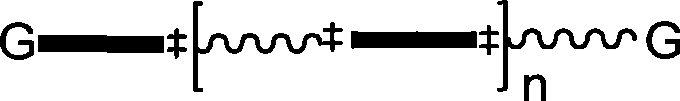

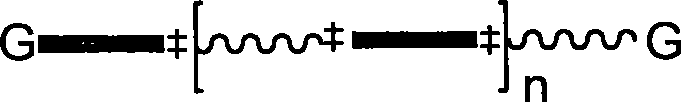

Multi-block biodegradable shape memory polymeric compound with regular structure and preparation thereof

A memory polymer, biodegradable technology, applied in the field of multi-block biodegradable shape memory polymer and its preparation, can solve the problems of high content of non-degradable chain segments, random arrangement, narrow adjustment range, etc., to achieve deformation fixation High recovery rate and recovery rate, controllable deformation recovery rate, and excellent biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

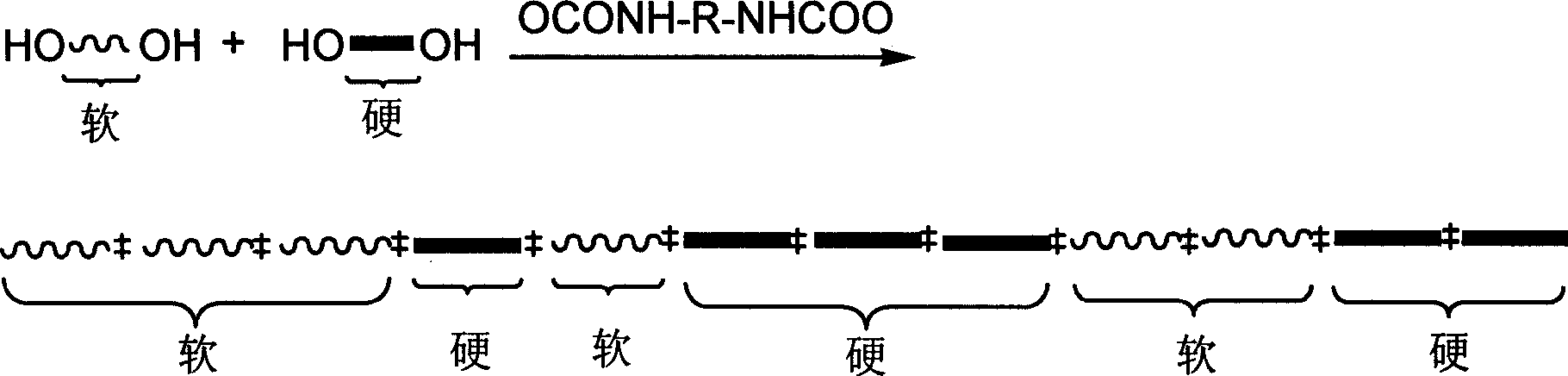

[0055] Example 1 Synthesis of ε-caprolactone / glycolide copolymer macromolecular diol (PCG-diol)

[0056] Add ε-caprolactone (CL, 51.3g, 0.45mol), glycolide (5.8g, 0.05mol), 1,4-butanediol (0.52g, 5.8 mmol), stir evenly, then add the catalyst stannous octoate (28.6mg, 0.05wt%), mix well, seal the tube after vacuumizing, and react at 120°C for 8h; the product is dissolved in chloroform, precipitated with excess methanol, and precipitated After repeated washing, the product was dried under vacuum at 50°C for 48 hours, and the obtained sample was recorded as PCG-diol (90 / 10, 10000), where 90 / 10 represents the molar ratio of ε-caprolactone to glycolide, and 10000 represents the designed number average molecular weight. The number average molecular weight of PCG-diol (90 / 10, 10000) is 10000, the polydispersity index is 1.49, and the melting point is 49.5°C.

[0057] Change the ratio of ε-caprolactone and glycolide or the ratio of monomer (the sum of ε-caprolactone and glycolide) a...

Embodiment 2

[0060] Example 2 Synthesis of L-lactide / glycolide copolymer macromolecular diol (PLLG-diol)

[0061] Add LLA (64.8g, 0.45mol), GA (5.8g, 0.05mol), BDO (0.52g, 5.8mmol) in the reaction flask that has been fully pumped / roasted, stir evenly, then add catalyst stannous octoate (35.3 mg, 0.05wt%), mix well, seal the tube after vacuuming, and react at 160°C for 8h; the product is dissolved in chloroform, precipitated with excess methanol, and the precipitate is dried under vacuum at 75°C for 48h after repeated washing. The obtained sample is recorded as PLLG-diol (90 / 10, 10000), with a number average molecular weight of 10500, a polydispersity index of 1.10, a glass transition temperature of 44.3 and a melting point of 136°C.

[0062] Table 2 Synthesis conditions and results of PLLG-diol macromolecular diol

[0063]

Embodiment 3

[0065] Add PCG-diol (90 / 10, 6000, 5.1 g, 0.81 mmol) into a three-necked flask equipped with a constant pressure dropping funnel, a thermometer and a nitrogen tube. TDI (1.7mmol, molar ratio to PCG-diol is 2.1:1), pre-polymerized at 80°C for 4 hours after the dropwise addition; then, add PLLG-diol (90 / 10, 6000, 5 grams, 0.81mmol) , chain extension reaction was carried out at 110°C for 8 hours; the temperature was lowered to 110°C, and 1 g of n-butanol was added for post-treatment, and the reaction was carried out for 1 hour; vacuum was applied to remove excess n-butanol to obtain P(LLG- mb-CG) multi-block copolymer with a molecular weight of 53000 and a soft segment / hard segment molar ratio of 50 / 50.

[0066] After the reaction is over, the polymer melt is added into the mold while it is hot, and a flake-like sample is obtained after cooling. A dumbbell-shaped sample is pressed with a dumbbell-shaped mold, and its effective size is 20×4×0.2~0.3 (mm). On a universal material t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com