Novel low odor, low carbon emitting PC/ABS alloy material and preparation

An alloy material and low-odor technology, applied in the field of polycarbonate/acrylonitrile-butadiene-styrene copolymer alloy materials and preparation, can solve problems such as complex molding and processing technology, and achieve physical and mechanical properties that are not affected, The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] Preparation of PP-g-MAH: dry mix 70% ABS resin, PP30%, maleic anhydride (MAH) 1.5%, initiator 1%, stearic acid 0.4% in a high-speed mixer for 3-5 minutes and enter the double Screw extruder, melt extruded, granulated for use. The processing technology is as follows: the temperature in the first zone is 170-190°C, the temperature in the second zone is 180-200°C, the temperature in the third zone is 180-200°C, the temperature in the fourth zone is 170-190°C; the residence time is 1-3 minutes, and the pressure is 12-18MPa .

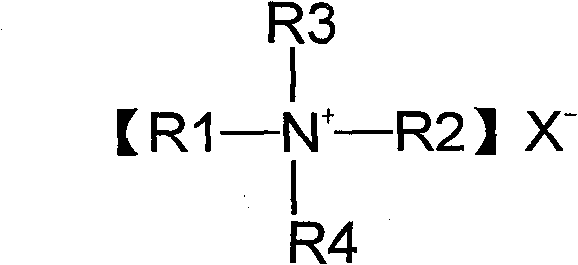

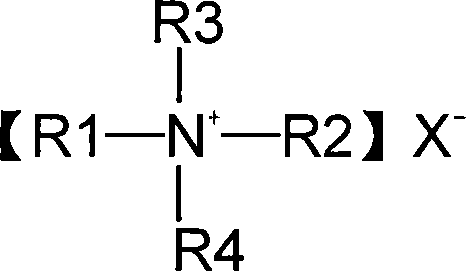

[0055] Preparation of hydrophobic odor inhibitor: Weigh 200g of attapulgite, add 2500ml of deionized water, and stir at high speed to form a suspension solution; stir at 80°C for 3 hours, and at the same time add 0.1g / ml of cetyltrimethyl Ammonium bromide aqueous solution 75ml; the reaction product was repeatedly suction filtered and washed several times, then dried in vacuum, activated at 200°C for 2 hours, crushed and sieved.

[0056] Preparation ...

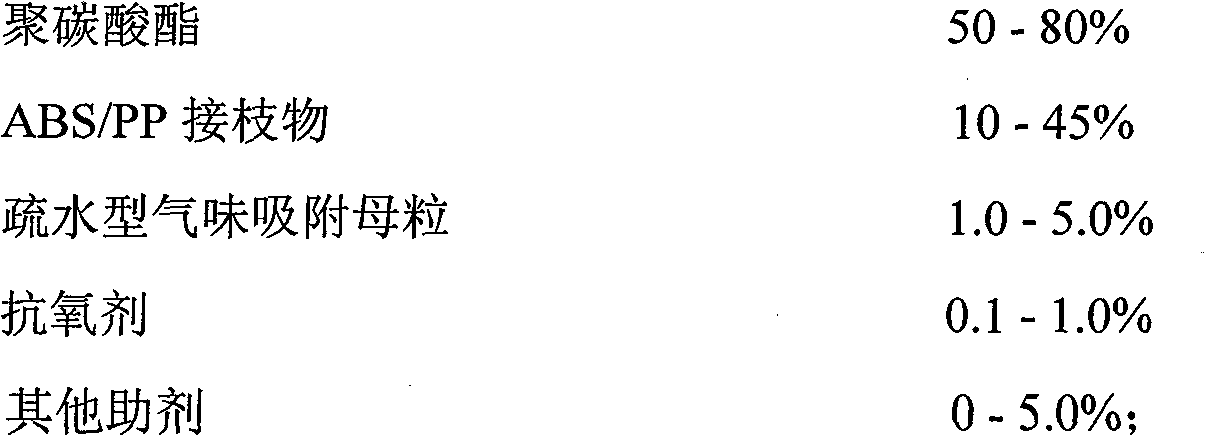

Embodiment 1

[0058] Preparation of PC / ABS alloy material: 52.6% polycarbonate, 45% ABS / PP graft, 2% hydrophobic odor adsorption masterbatch, 0.1% antioxidant 1010 and 0.2% antioxidant 168 and 0.1% lubrication The agent is dry-mixed in a high-speed mixer for 3 to 5 minutes, then melted and extruded in a twin-screw extruder, and granulated. -240°C, four zone 215-225°C; residence time 1-2 minutes, pressure 8-10MPa.

Embodiment 2

[0060] 50.6% polycarbonate, 45% ABS / PP graft, 4% hydrophobic odor absorption masterbatch, 0.1% antioxidant 1010, 0.2% antioxidant 168 and 0.1% lubricant, and all the other operations are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com