Sewage treatment device with pretreatment function

A sewage treatment device and pretreatment technology, applied in water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc., can solve the problem of inconvenient sewage rapid treatment, increase quality, and realize waste heat recovery Organization, the effect of increasing the efficiency of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

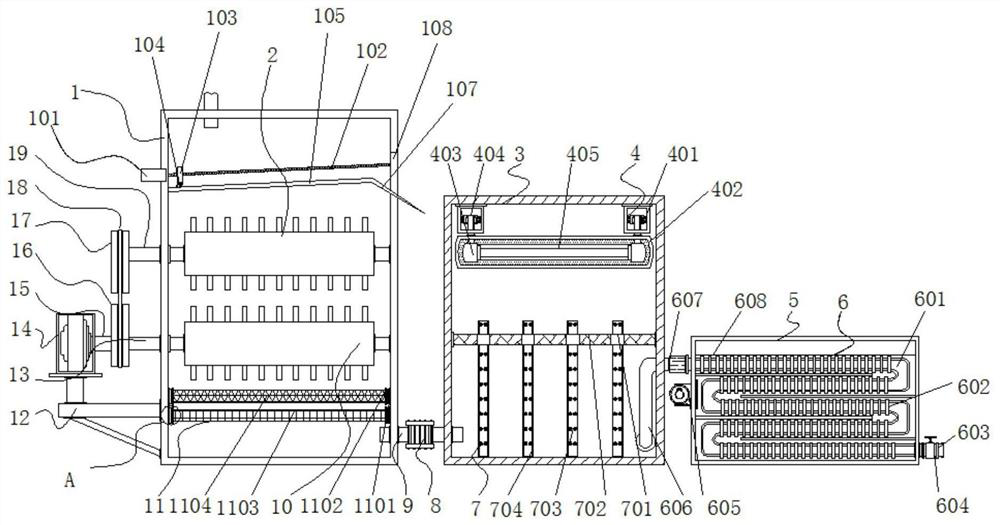

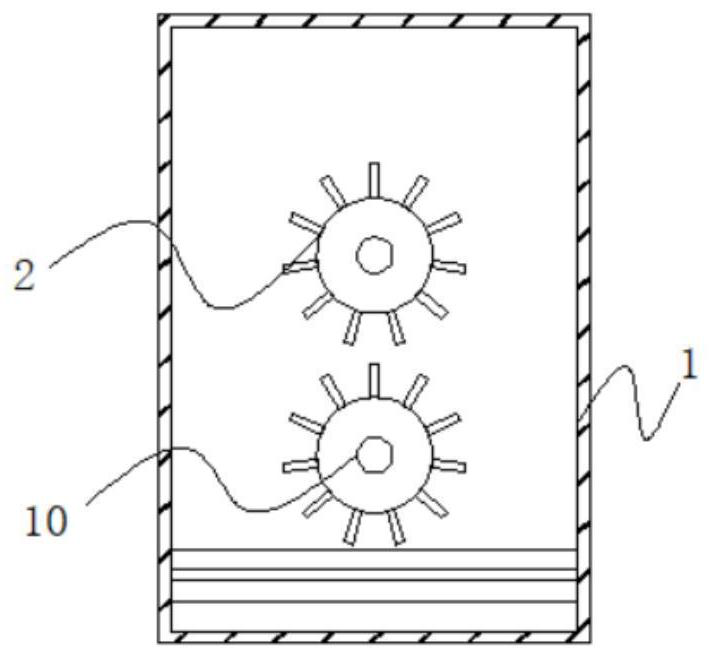

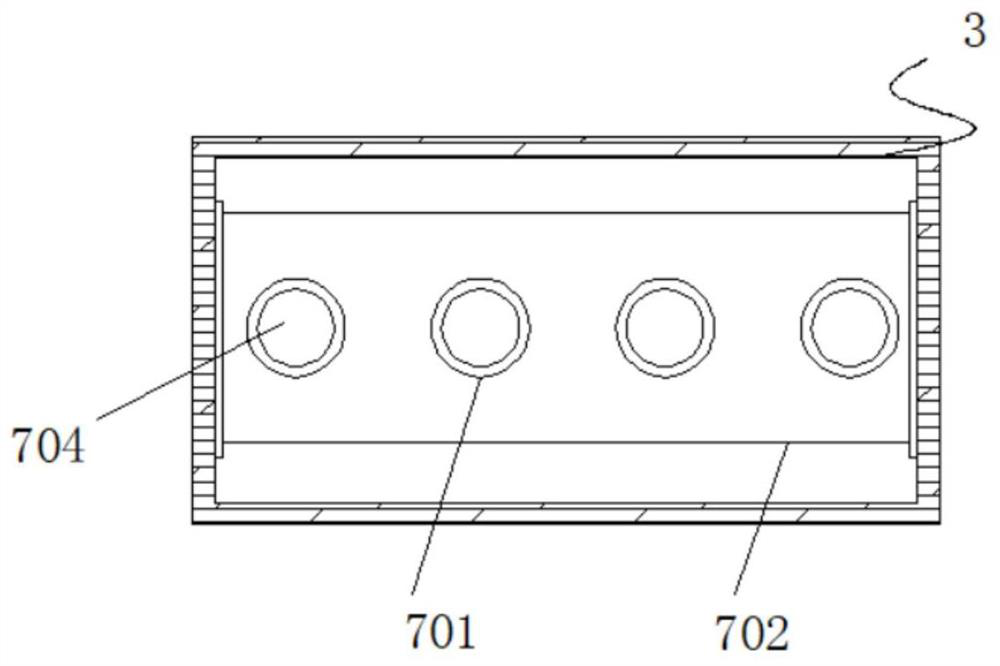

[0040] Example 1: See Figure 1-7 , a sewage treatment device with a pretreatment function, comprising a box body 1, a tank body 3 and a discharge box 5;

[0041] The upper part of the inner cavity of the box body 1 is obliquely equipped with a lead-out plate 105, the upper left side of the inner cavity of the box body 1 is fixedly installed with a rotating motor 101, and the right side of the motor 101 is fixedly connected with a reciprocating screw rod 102. The reciprocating screw rod 102 is located on the top of the lead-out plate 105, and a scraper 103 is movably connected between the inner walls on both sides of the upper part of the box body 1, and the scraper 103 is located on the upper side of the lead-out plate 105. The scraper 103 and the The reciprocating screw rod 102 is spirally connected, the lower side of the scraper 103 is fixedly connected with a brush 104, and several groups of through holes 106 are opened through the guide plate 103, and the side wall of the...

Embodiment 2

[0046] Embodiment 2: The sterilization and disinfection mechanism 4 is made up of fixed seat 401, mounting seat 402, connecting sleeve block 403, connecting rod 404, ultraviolet sterilizing lamp tube 405, connecting block 406, connecting seat 407 and limit seat 408. Fixedly connected to both sides of the top inside the tank body 3, the inside of the fixed seat 401 is provided with a connecting rod 404, and both sides of the top of the connecting rod 404 are fixedly connected with a connecting block 406, and the width of the connecting block 406 outside is smaller than that of the connecting seat 407. The width of the connecting block 406 is symmetrically distributed with respect to the vertical center line of the connecting rod 404. The bottom end of the connecting rod 404 is fixedly connected with a connecting block 403, and an ultraviolet germicidal lamp tube 405 is arranged between the connecting block 403. The ultraviolet germicidal lamp The model of the tube 405 can be 320...

Embodiment 3

[0048] Embodiment 3: The waste heat recovery mechanism 6 is composed of a conduit 601, a fin 602, an outlet pipe 603, a valve 604, a hot air blower 605, a suction pipe 606, a first water pump 607 and a placement tank 608, which is fixedly connected to the discharge box 5, the inside of the placement groove 608 is provided with a conduit 601, the outside of the conduit 601 is fixedly connected with fins 602, the bottom end of the conduit 601 is fixedly connected with an outlet pipe 603, and one side of the outlet pipe 603 is provided with a valve 604, The top of the conduit 601 runs through the inside of the tank body 3, a first water pump 607 is provided on one side of the top of the suction pipe 606, and the model of the first water pump 607 can be WQ, and the hot air blower 605 is arranged on one side of the placement tank 608 , the model of the hot air blower 605 can be FP-51WA;

[0049] The inner diameter of the placement groove 608 is greater than the outer diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com