Measurement of harmful substance nonyl phenol polyethenoxy ether content in electric and textile

A nonylphenol polyoxyethylene ether, electronic and electrical technology, applied in the field of determination of nonylphenol polyoxyethylene ether content, can solve the problem of non-measurement of nonylphenol polyoxyethylene ether content, and meet the requirements of research and production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

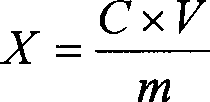

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, the mensuration of nonylphenol polyoxyethylene ether in earplug cloth cover:

[0023] Take the sample to be tested and pulverize it, accurately weigh 1.0005g, put it into a Soxhlet extraction device, add 180ml of methanol, and reflux for 6 hours; take it out and cool it to room temperature, use a rotary evaporator to concentrate the extract to nearly dryness at 40°C, and add 5ml of methanol .

[0024] Prepare a glass tube (20mm × 350mm), one end of which is plugged with glass wool washed with a solvent, and a 250ml flat-bottomed ground flask is placed below it for reception; add 1g of anhydrous sodium sulfate, 4g of diatomaceous earth and 1g of anhydrous sodium sulfate, rinse the column with 40ml of methanol, do not collect the rinse. Add the concentrated sample solution, then elute the column with 100ml of methanol and collect all the eluate. Concentrate to 2ml at 40°C with a rotary evaporator, then transfer to a 25ml brown volumetric flask, dilute to t...

Embodiment 2

[0048] Embodiment 2, the mensuration of nonylphenol polyoxyethylene ether in plastic color masterbatch (electronic product raw material):

[0049] Take the sample to be tested and pulverize it, accurately weigh 1.0005g, put it into a Soxhlet extraction device, add 180ml of methanol, and reflux for 6 hours; take it out and cool it to room temperature, use a rotary evaporator to concentrate the extract to nearly dryness at 40°C, and add 5ml of methanol .

[0050] Prepare a glass tube (20mm × 350mm), one end of which is plugged with glass wool washed with a solvent, and a 250ml flat-bottomed ground flask is placed below it for reception; add 1g of anhydrous sodium sulfate, 4g of diatomaceous earth and 1g of anhydrous sodium sulfate, rinse the column with 40ml of methanol, do not collect the rinse. Add the concentrated sample solution, then elute the column with 100ml of methanol and collect all the eluate. Concentrate to 2ml at 40°C with a rotary evaporator, then transfer to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com