Composite large V multi-wedge plate belt pulley and forming method

A molding method and pulley technology, applied in belts/chains/gears, molding tools, manufacturing tools, etc., can solve the problems of high mass production cost, narrow transmission power range, and difficult processing, and achieve low equipment accuracy and tonnage requirements. , The effect of a wide range of transmission power and less processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

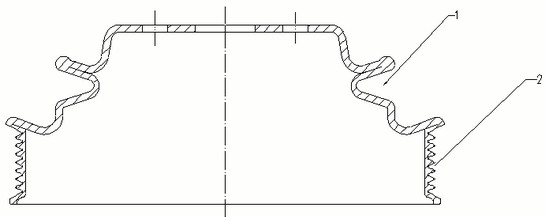

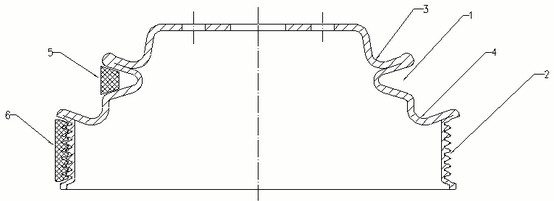

[0036] figure 1 Among them, the present invention is made of a thin steel plate, and the thickness of the thin steel plate is 3mm. The V-shaped groove 1 and the PK-shaped groove 2 are integrated. The difference between the outer diameter D of the PK-shaped groove 2 and the outer diameter d of the V-shaped groove 1 is: D-d=20mm. The quantity range of PK type groove is 8PK. The side of the wheel body includes a V-shaped groove 1 on the upper part and a PK-shaped groove 2 on the lower part. The concave lower arc surface 4 is connected with the PK type groove 2 .

[0037] figure 2 Among them, the V-shaped groove 1 is equipped with a V-belt 5, and the PK-shaped groove 2 is equipped with a PK belt 6.

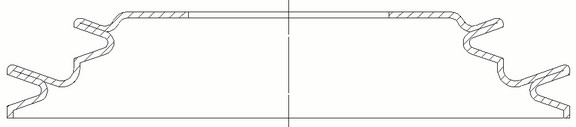

[0038] Figure 5 , 6 , 7, 8, forming method of the present invention is a kind of processing method that adopts thin steel plate to be manufactured into composite large V multi-ribbed belt pulley, and it comprises following main operations:

[0039] A. Blanking: Punch the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com