Method and device for preparing high quality high ferrotitanium alloy based on aluminothermy reduction

A high-quality, ferroalloy technology, applied in the field of alloy preparation, can solve the problems of high production cost, high oxygen content, and high use restrictions of ferro-titanium, and achieve the effects of low production cost, wide source of raw materials, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

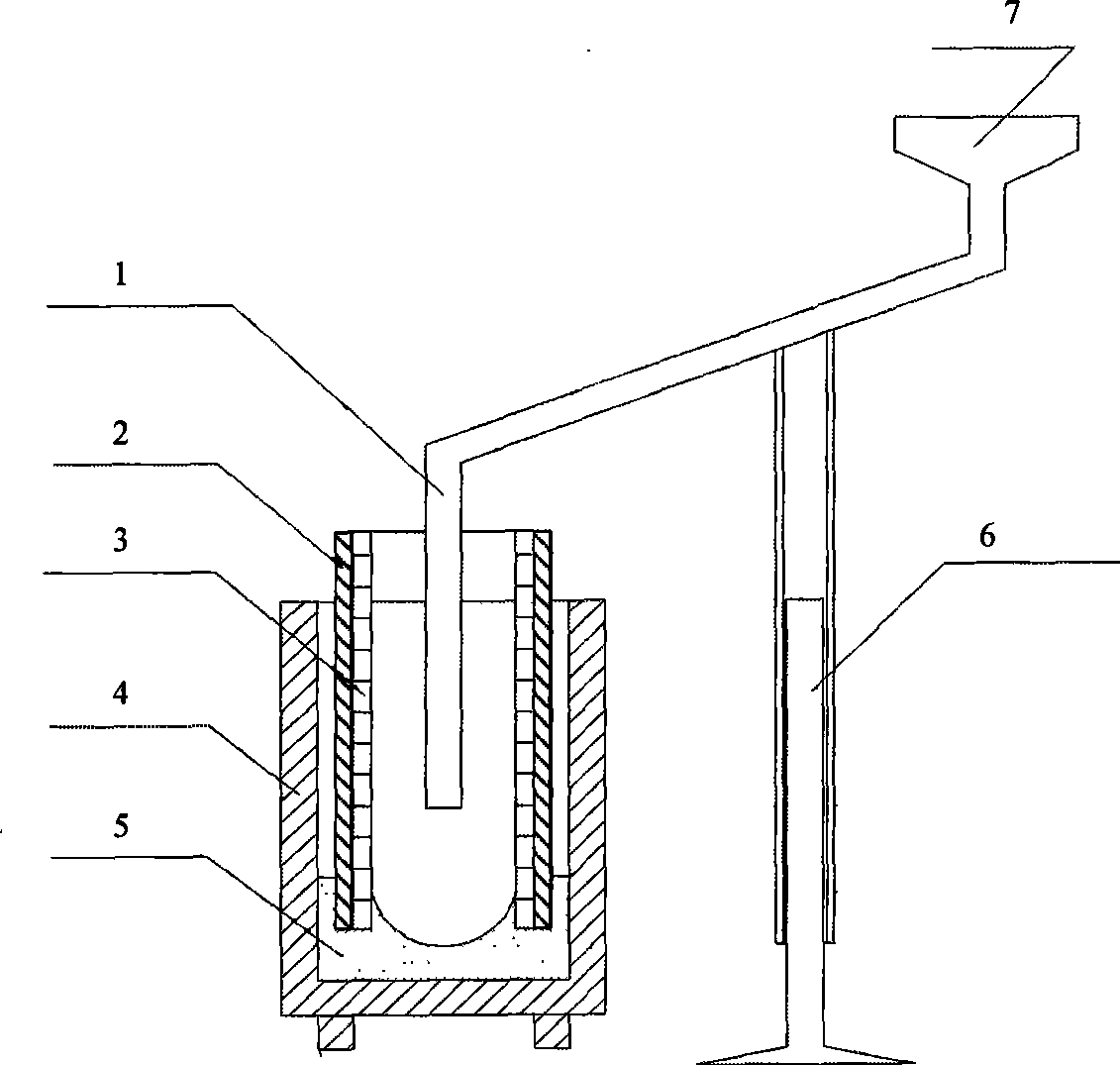

[0037] A device for preparing high-quality high-titanium ferroalloys based on aluminothermic reduction such as figure 1 As shown, the device includes a feeding device and a smelting device. The feeding device includes a feeding funnel 7 and a feeding pipe 1. The smelting device includes a resistance furnace 4, a magnesia bottom nest 5, a heat-resistant steel pipe 2, and a magnesia lining 3; the feeding device Connect the casing lifting and fixing device 6, and the height of the feeding device can be adjusted through the casing lifting and fixing device 6.

[0038] The inner wall of the heat-resistant steel pipe 2 is sprayed with magnesia lining 3 and fixed in the resistance furnace 4. A refractory material is provided between the heat-resistant steel pipe 2 and the inner wall of the resistance furnace 4, and the bottom of the resistance furnace 4 is provided with a magnesia bottom nest 5 The bottom of the feeding funnel 7 is connected to the feeding pipe 1, and the other end o...

Embodiment 2

[0043] The device that adopts is with embodiment 1.

[0044] The thermite reducing agent is preheated to 700°C and melted into a liquid state to form a molten metal pool. The aluminotherm reducing agent is an Al-based alloy containing 5wt% Mg; a layer of mold slag is covered on the surface of the aluminotherm reducing agent; rutile, iron concentrate Mix with slagging agent and ball mill until the particle size is less than 80 mesh, then preheat to 900°C, and add it into the metal molten pool formed by liquid thermite reducing agent through a feeding device, wherein the slag forming agent is composed of Na 2 O 10%, with CaF 2 20%, the balance is CaO; the feeding amount is rutile: iron concentrate: slagging agent: thermite reducing agent = 1.0: 0.05: 0.18: 0.48 by weight; smelting for 30 minutes after the feeding is completed.

[0045] Inject CaB6 into the metal molten pool in the resistance furnace through the injection pipe in the feeding pipe , The carrier gas is argon, and...

Embodiment 3

[0047] The device that adopts is with embodiment 1.

[0048] The thermite reducing agent is preheated to 800°C and melted into a liquid state to form a molten metal pool. The aluminotherm reducing agent is an Al-based alloy containing 20wt% Mg and 5wt% Li; a layer of mold slag is covered on the surface of the aluminotherm reducing agent; rutile, Iron concentrate and slagging agent are mixed and ball-milled until the particle size is less than 80 mesh, then preheated to 1200°C, and added to the metal molten pool formed by liquid thermite reducing agent through a feeding device, wherein the slag forming agent is composed of Na 2 O 10%, with CaF 2 20%, the balance is CaO; the feeding amount is rutile: iron concentrate: slagging agent: thermite reducing agent = 1.0: 0.06: 0.20: 0.50 by weight; smelting for 20 minutes after the feeding is completed.

[0049] Inject CaB into the molten metal pool in the resistance furnace through the injection pipe in the feeding pipe 6 , the carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com