Anti-protease acidic alpha-galactosidase Aga-F75 and gene and application thereof

A technology of galactosidase and aga-f75, which is applied in the field of genetic engineering and can solve problems such as inability to hydrolyze various substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

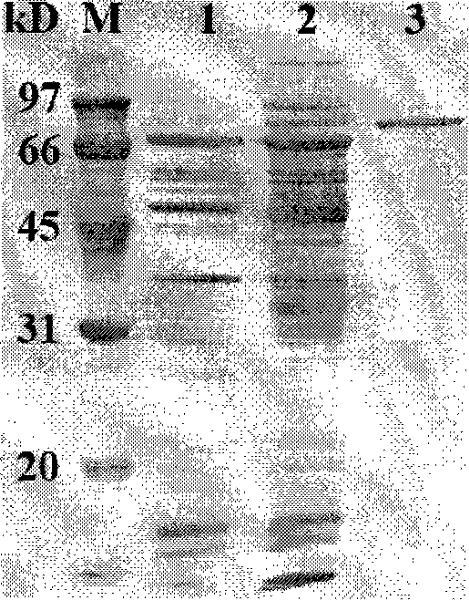

Embodiment 1

[0152] Example 1 Isolation of Gibberela.sp.F75 and its enzyme-producing properties

[0153] After the strain Gibberela.sp.F75 grew on PDA medium for 3-5 days, the hyphae were white and the roots were red. Primers designed according to the conserved sequence of 18S rDNA of filamentous fungi were used to amplify the 18S rDNA of the strain by PCR, and the sequencing results were compared with the nucleotide sequences in the Genbank database. accession No.AB237662) has the highest similarity of 99%. Combined with morphological observation, it can be proved that the strain is Rhizopus, named Gibberella.sp.F75. Soybean meal was added as an inducer and carbon source to the enzyme-producing medium (4% K 2 HPO 4 , 0.28% (NH 4 ) 2 SO 4 , 0.12% CaCl 2 , 0.12% Urea, 0.12% MgSO 4 , 0.02% Mannanose, 0.02% Yeast extract, 3% soybean meal as carbon source), 30°C, 250rpm shaking culture for 5 days, the bacterial liquid was centrifuged, and the supernatant was taken to measure the enzyme...

Embodiment 2

[0154] Example 2 Cloning of gibberella α-galactosidase coding gene aga-F75

[0155] Extraction of Gibberela (Gibberela.sp.F75) genomic DNA: centrifuge the Gibberela liquid cultured at 30°C for 7 days at 6000rpm for 10min. Take 100mg of mycelia and add 500μL of sterile water to wash, centrifuge to get the precipitate. The precipitate was resuspended in 500 μL extract mixture, incubated at 37°C for 60 min, and centrifuged at 10,000 rpm for 10 min to remove the precipitate. The supernatant was extracted sequentially with equal volumes of phenol, phenol:chloroform, and chloroform. Take the upper layer solution and add 0.6-1 times the volume of isopropanol to precipitate at room temperature for 10 minutes. Centrifuge at 12000rpm for 15min. The precipitate was washed with 70% ethanol, centrifuged slightly, dried and dissolved in 30 μL sterile water for later use.

[0156] According to the published conserved sequence of α-galactosidase, degenerate primers P1, 5′-GAYGAYGGNTGGTTYG...

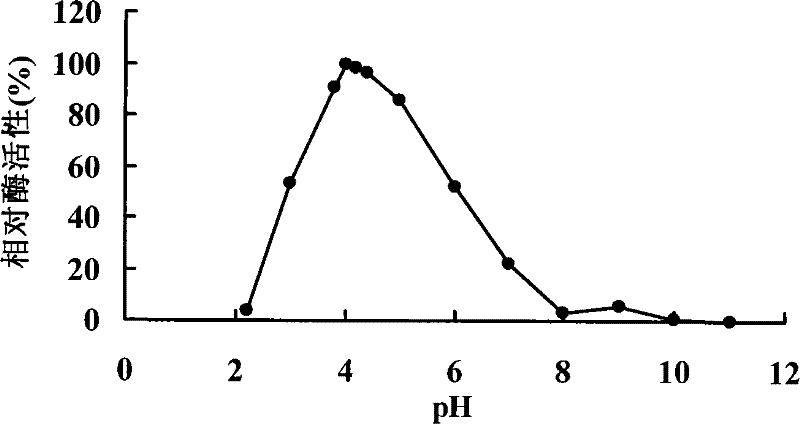

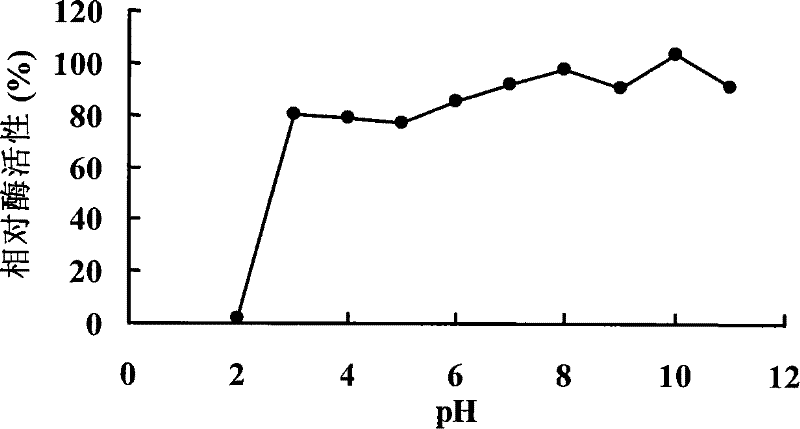

Embodiment 3

[0158] Example 3 Activity analysis of α-galactosidase.

[0159] Enzyme activity was determined by the pNPG method. Dissolve pNPG in 0.1mol / L McIlvaine buffer to make the final concentration 2mmol / L. Mix 20 μL of enzyme solution, 230 μL of McIlvaine buffer and 250 μL of 2mM pNPG, and shake well. After incubating at 37°C for 5 min, 1.5 mL of 1M Na was added to the reaction solution 2 CO 3 solution to terminate the reaction. The OD value was measured at 405nm, and the enzyme activity was expressed by the production of p-nitrophenol (pNP). After adding enzyme solution and buffer to the control tube, add Na first 2 CO 3 The solution was then added with pNPG solution.

[0160] Enzyme activity (U / mL) unit definition: The amount of enzyme needed to decompose pNPG to release 1 μmol pNP per minute at 37°C is defined as one enzyme activity unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com