Method for synthesizing zinc oxide nano tube array by low-temperature hydrothermal method

A technology of zinc oxide nanotubes and hydrothermal method, which is applied in the direction of zinc oxide/zinc hydroxide, etc., can solve the problems of unfavorable environmental protection, large capital investment, large energy consumption, etc., and achieve short production cycle, low reaction temperature and high return on investment high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

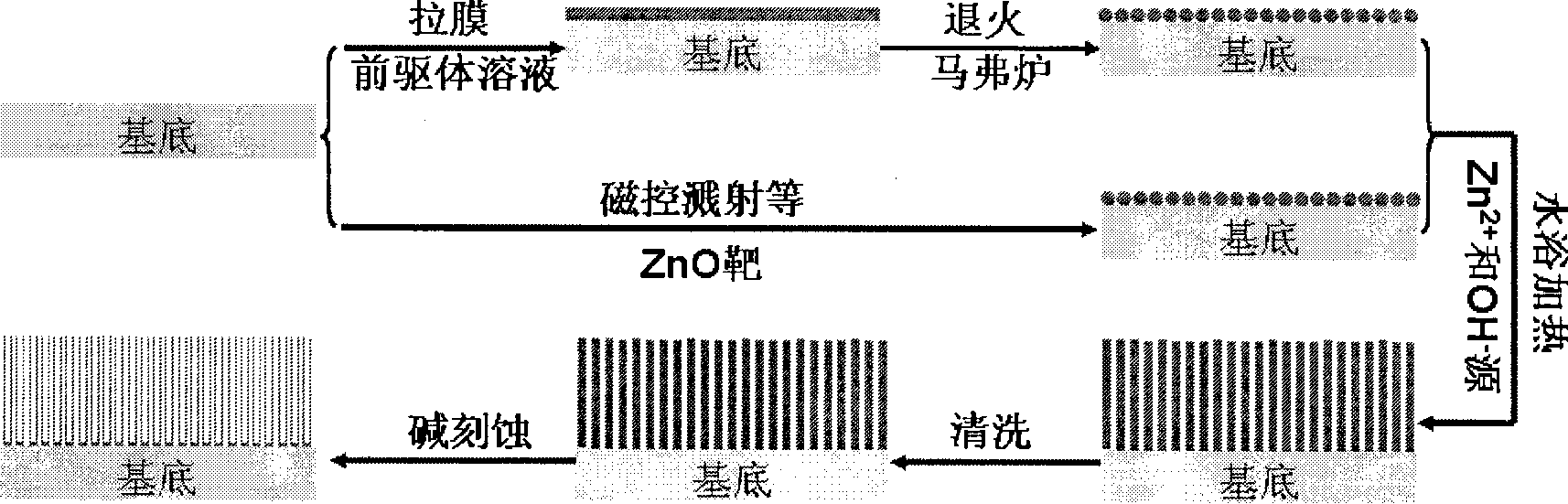

[0028] (1) Preparation of ZnO seed layer

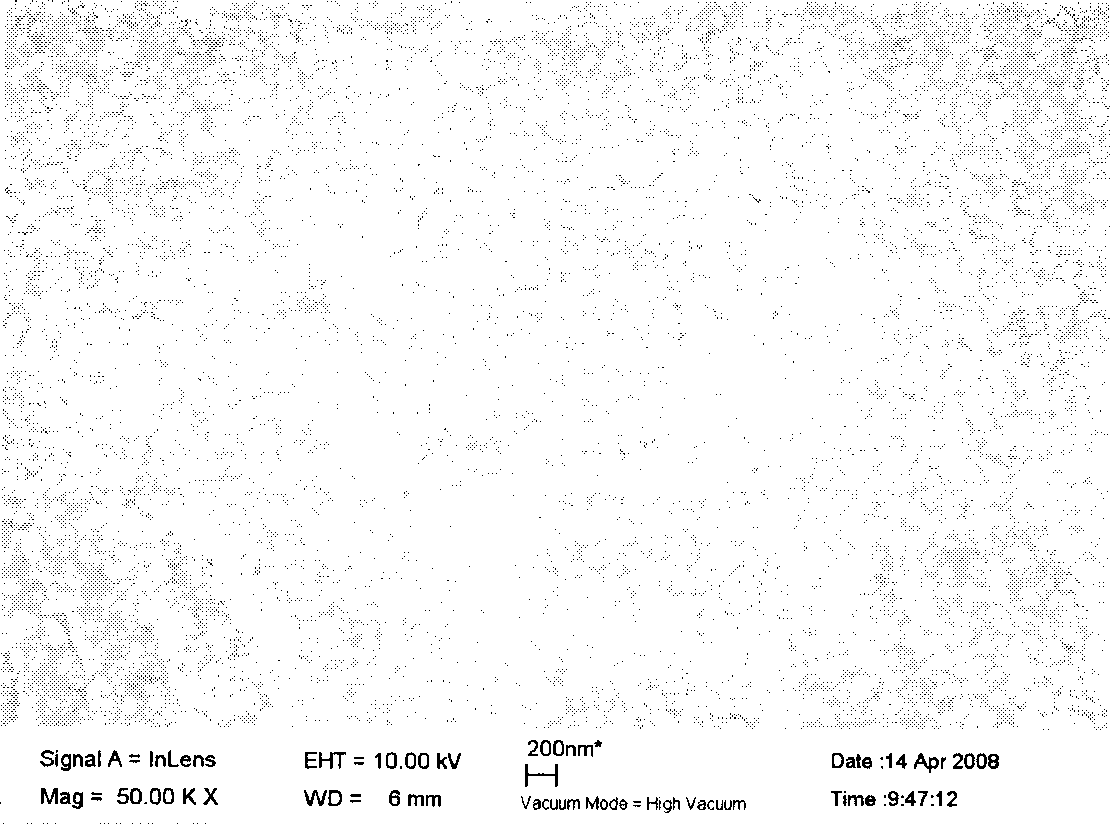

[0029] Zinc acetate and monoethanolamine are used as precursor raw materials, and they are dissolved in ethylene glycol methyl ether to form a solution with a concentration of 0.5M, stirred at 50°C for 10 minutes, and then formed on the conductive glass by film pulling. layer amorphous film. The sample is then transferred to a muffle furnace and annealed for 1 hour at a temperature of 300 °C, and the amorphous film is transformed into a ZnO nanocrystalline seed layer (such as image 3 ).

[0030] (2) Low temperature hydrothermal growth of ZnO nanowires

[0031] Using 0.01M zinc nitrate as zinc source, 0.01M hexamethylenetetramine provides OH - Source, grow ZnO nanowires for 2 hours under the condition of airtight and water bath temperature of 80°C, Figure 4 is a cross-sectional view of ZnO nanowire arrays on conductive glass. After finishing the growth of ZnO nanowires, the conductive glass with ZnO nanowires grown was washed wi...

Embodiment 2

[0035] (1) Preparation of ZnO seed layer

[0036] Zinc acetate and monoethanolamine are used as precursor raw materials, and they are dissolved in ethylene glycol methyl ether to form a solution with a concentration of 0.5M, stirred at 50°C for 10 minutes, and then formed on the conductive glass by film pulling. layer amorphous film. The sample was then transferred to a muffle furnace and annealed at 300°C for 1 hour, and the amorphous film was transformed into a ZnO nanocrystalline seed layer on the conductive glass substrate.

[0037] (2) Low temperature hydrothermal growth of ZnO nanowires

[0038] Using 0.5M zinc sulfate as zinc source, 0.5M hexamethylenetetramine provides OH - Source, under the condition of airtight, water bath temperature is 80 ℃ for 2 hours to obtain ZnO nanowires. After finishing the growth of ZnO nanowires, the conductive glass with ZnO nanowires grown was washed with deionized water. Dry at 50° C. for 0.5 hours.

[0039] (3) ZnO nanowires are ch...

Embodiment 3

[0042] (1) Preparation of ZnO seed layer

[0043] A layer of ZnO seed layer was sputtered on the plastic substrate (PET) by magnetron sputtering, the sputtering parameters were: power 100W, air pressure 0.6Pa; Ar gas flow 120 / sccm; time 1 minute.

[0044] (2) Low temperature hydrothermal growth of ZnO nanowires

[0045] Using 0.025M zinc sulfate as zinc source, 0.025M hexamethylenetetramine provides OH -Source, under the condition of airtight, water bath temperature is 80 ℃ for 2 hours to obtain ZnO nanowires. After finishing the growth of ZnO nanowires, the conductive glass with ZnO nanowires grown was washed with deionized water. Dry at 50° C. for 0.5 hours.

[0046] (3) ZnO nanowires are chemically etched into ZnO nanotubes

[0047] Transfer the substrate grown with ZnO nanowires into a closed hydrothermal reactor. The reaction raw material in the hydrothermal reactor is 0.06M NaOH aqueous solution, etched at a reaction temperature of 40°C for 20 minutes, and can be obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com