Method for preparing mesoporous titanium silicate molecular sieve

A titanium-silicon molecular sieve and mesoporous technology, which is applied in the field of preparation of mesoporous molecular sieve catalytic materials, can solve the problems of titanium-silicon molecular sieves with great differences in catalytic performance, reduced catalytic reaction efficiency, poor product repeatability, etc., to achieve mild reaction conditions and synthetic raw materials The effect of easy availability, good selectivity and conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

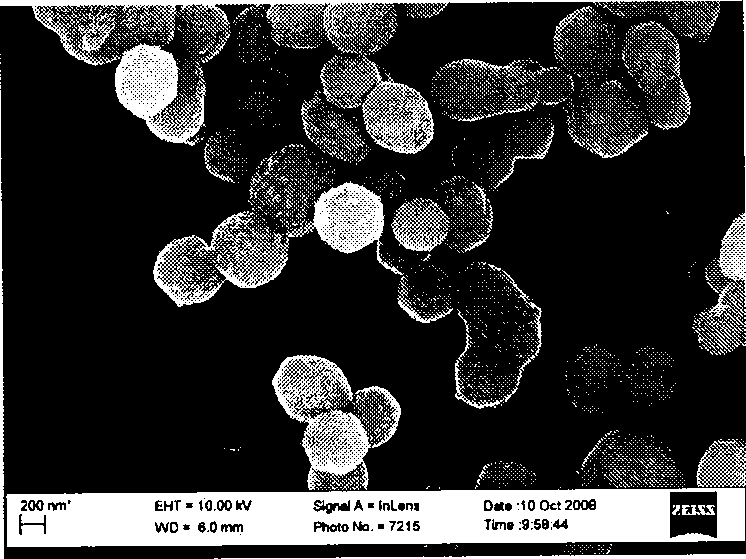

[0020] Dodecyltrimethylammonium bromide is dissolved in deionized water to form a uniform solution with a mass percentage concentration of 0.7%, adding ammonia water to adjust the pH value of the solution to 10, and ethyl tetrasilicate is added to the solution (silicon source The molar ratio to dodecyltrimethylammonium bromide is 7), and magnetically stirred for 4h. The product was filtered, washed with deionized water, and dried at 30 °C. Calcined at 550°C for 6h to obtain white silica mesoporous molecular sieves (see figure 1 ).

[0021] Take silica mesoporous molecular sieve and add it to ethanol for dispersion (mass percentage concentration is 3%), dissolve tetraethyl titanate in ethanol (molar ratio of titanium / silicon is 0.15) and add to silica mesoporous molecular sieve ethanol In the solution, stirred and reacted at 30°C for 4h, the product was filtered, washed with ethanol to obtain a white powder, dried at 90°C, and calcined at 300°C for 6h to obtain a mesoporous t...

Embodiment 2

[0024] Dissolve cetyltrimethylammonium bromide in deionized water to form a uniform solution with a mass percent concentration of 0.7%, add ammonia water to adjust the pH value of the solution to 10, and mix ethyl orthosilicate and diphenyldimethoxy Add silane into the solution (the molar ratio of silicon source to hexadecyltrimethylammonium bromide is 7), and magnetically stir for 6h. The product was filtered, washed with deionized water, and dried at 30 °C. Calcined at 550°C for 6 hours to obtain white silica mesoporous molecular sieves.

[0025] Take silica mesoporous molecular sieve and add it to ethanol for dispersion (mass percentage concentration is 3%), dissolve tetraethyl titanate in ethanol (molar ratio of titanium / silicon is 0.15) and add to silica mesoporous molecular sieve ethanol In the solution, stirred and reacted at 30°C for 4h, the product was filtered, washed with ethanol to obtain a white powder, dried at 90°C, and calcined at 300°C for 6h to obtain a meso...

Embodiment 3

[0028] Hexadecyltrimethylammonium bromide is dissolved in deionized water to form a uniform solution with a mass percent concentration of 1.7%, adding ammonia water to adjust the pH value of the solution to 10, adding sodium orthosilicate to the solution (silicon source and ten The molar ratio of hexyltrimethylammonium bromide is 7), and magnetic stirring is carried out for 6h. The product was filtered, washed with deionized water, and dried at 30 °C. Calcined at 550°C for 6 hours to obtain white silica mesoporous molecular sieves.

[0029] Get silica mesoporous molecular sieve and join in ethanol and disperse (mass percent concentration is 3%), dissolve titanium trichloride in isopropanol (the molar ratio of titanium / silicon is 0.15) add to silica mesoporous molecular sieve In the ethanol solution, stirred and reacted at 30°C for 4h, the product was filtered, washed with ethanol to obtain a white powder, dried at 90°C, and calcined at 300°C for 6h to obtain a mesoporous tita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com