Method for manufacturing single-chip-integrated GaAs base PHEMT and PIN diode

A PIN diode, monolithic integration technology, applied in the field of compound semiconductor materials and devices, can solve the problems of unfavorable PHEMT circuit potential conversion, large on-resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail in conjunction with specific embodiments and with reference to the accompanying drawings.

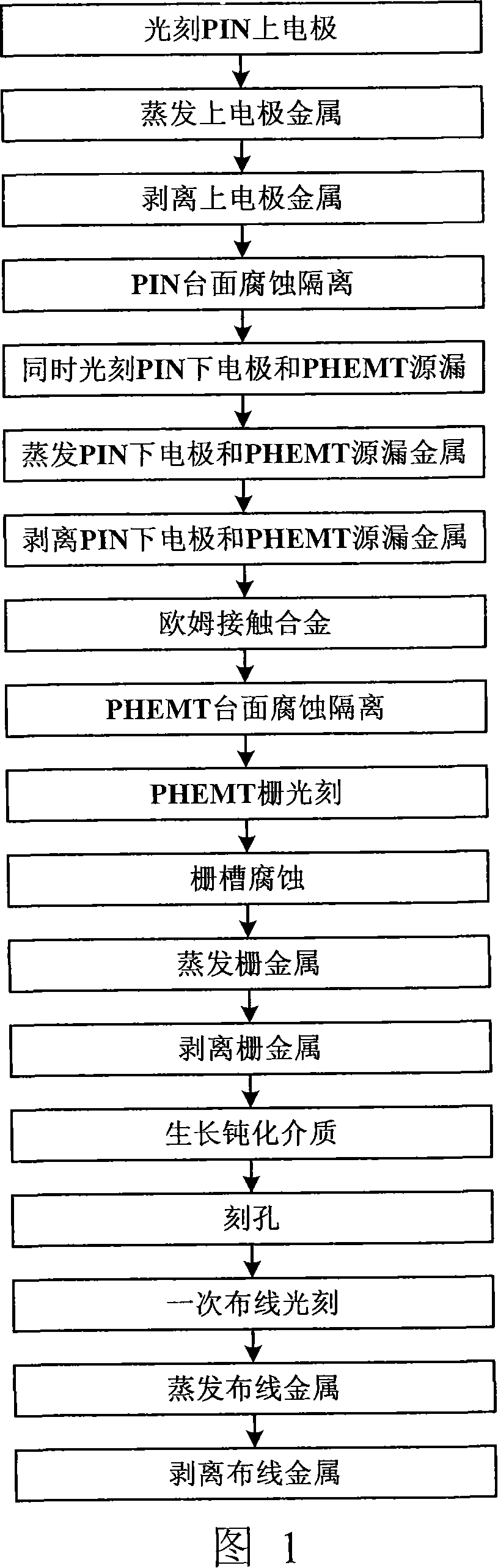

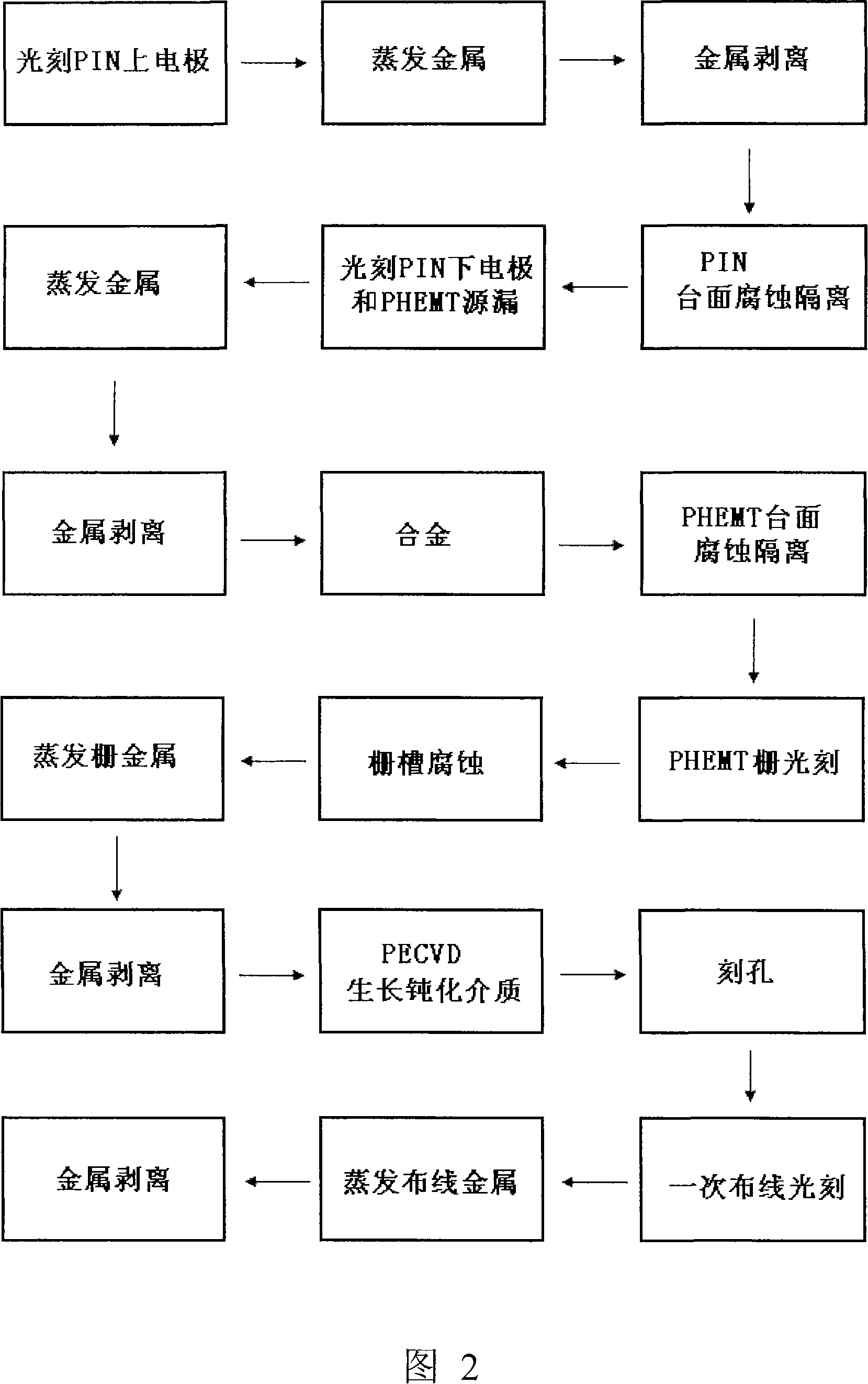

[0035] Such as figure 1 As shown, figure 1 It is a flow chart of the method for manufacturing monolithic integrated GaAs-based PHEMT and PIN diodes provided by the present invention. The method sequentially includes the following process steps: photoetching PIN upper electrode, evaporating upper electrode metal, stripping upper electrode metal, PIN mesa corrosion isolation, and simultaneous Lithography PIN bottom electrode and PHEMT source and drain, evaporation of PIN bottom electrode and PHEMT source and drain metal, stripping PIN bottom electrode and PHEMT source and drain metal, ohmic contact alloy, PHEMT mesa corrosion isolation, PHEMT gate photolithography, grid groove corrosion, evaporation gate Metal, stripping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com